Core Cognition: CNC Machined Components—Beyond “Machined Parts”

Core Traits of CNC Machined Components: What Makes Them Unique

1. Program-Driven Precision (Tolerances Measured in Microns)

- Definition: CNC’s preprogrammed toolpaths mean components meet ultra-tight tolerances (often ±0.001–0.005mm)—1/20 the width of a human hair. This precision isn’t accidental; it’s coded into every G-code line. For example, a CNC-machined aerospace fastener must fit into a turbine blade hole with zero play—even a 0.002mm mismatch could cause vibration at 30,000ft.

- Real-World Example: Last year, I machined titanium EV motor shafts with a tolerance of ±0.003mm. The client tested each shaft with a laser scanner—if it deviated even 0.001mm, it was rejected. Every shaft we made passed.

- Craftsman’s Insight: “Precision here isn’t about ‘being careful’—it’s about writing good code. I once made a mistake in a G-code line (typed X20.005 instead of X20.000), and the first 10 shafts were too big. Now, I double-check every program with a simulator before hitting ‘cycle start.’ Code is your blueprint—get it right, and the parts follow.”

2. Multi-Axis Versatility (Complex Shapes No Manual Process Can Match)

- Definition: Unlike manual machines (limited to 2–3 axes), CNC machines (3-axis, 5-axis, even 7-axis) can cut complex 3D shapes: curved aerospace turbine blades, hollow medical implant stems, or angled EV battery tray brackets. 5-axis CNC, for example, tilts the workpiece and tool simultaneously—letting you cut every surface of a component in one setup.

- Common Complex Examples:

|

Component Type

|

CNC Axis Type

|

Key Feature (Impossible with Manual Machining)

|

|

Aerospace Turbine Blade

|

5-axis

|

Curved leading edge (0.5mm thick) + internal cooling channels

|

|

Medical Hip Implant

|

5-axis

|

Tapered stem with porous surface (for bone integration)

|

|

EV Battery Tray Bracket

|

3-axis

|

Multiple angled holes (±0.005mm alignment)

|

- Craftsman’s Insight: “I once made a 5-axis CNC-machined robotic surgery tool—a thin, curved forceps tip (0.8mm wide) that had to fit through a 5mm incision. Manual machining would have broken the tool 10 times. With 5-axis, we cut it in one pass, no bending, no breakage. CNC turns ‘impossible’ shapes into ‘routine.’”

3. Automated Consistency (10,000 Parts = 10,000 Identical Results)

- Definition: CNC machines run 24/7 with minimal human intervention—automatic tool changers (ATCs) swap tools mid-job, chip conveyors clear waste, and in-machine probes check dimensions. This means every component in a batch is identical: a CNC shop can produce 100,000 EV door hinges with a rejection rate <0.05% (Source: Automotive CNC Quality Report 2025).

- Real-World Impact: A client once needed 50,000 plastic sensor housings for a smart home device. We set up a CNC router with an ATC (10 tools) and ran it overnight. In 8 hours, it made 2,000 housings—all with the same hole alignment, no burrs, no size variation. Manual machining would have taken 5 people a week to make that many.

- Craftsman’s Insight: “Consistency is CNC’s superpower. I used to manually machine 100 brackets a day—by the 80th one, my hands were tired, and the parts got slightly off. With CNC, the 100th part is the same as the first. It frees you from repetition so you can focus on solving problems, not repeating cuts.”

4. Material Adaptability (From Titanium to Carbon Fiber)

- Definition: CNC machines handle nearly any rigid material—from hard metals (titanium, Inconel) to lightweight plastics (PEEK, ABS) and high-strength composites (carbon fiber). CNC’s adjustable cutting parameters (speed, feed rate, coolant) let you tailor the process to the material’s “personality”: slow speeds for tough titanium, high speeds for soft aluminum.

- Material-Specific CNC Tips:

|

Material

|

CNC Cutting Speed (Vc)

|

Key Adjustment

|

|

Titanium (Ti-6Al-4V)

|

30–50 m/min

|

High coolant pressure (10MPa) to reduce heat

|

|

Aluminum (6061-T6)

|

300–400 m/min

|

Sharp carbide tools to avoid burring

|

|

Carbon Fiber Composite

|

100–150 m/min

|

Diamond-coated tools to prevent fiber fraying

|

- Craftsman’s Insight: “Carbon fiber was my worst enemy at first—CNC tools would fray the fibers, making the component weak. I switched to diamond-coated end mills and slowed the feed rate by 20%—now the edges are smooth, no fraying. Every material speaks a different language; CNC lets you learn its dialect.”

Key CNC Processes for Making CNC Machined Components

1. CNC Turning (For Rotational Components—The “Digital Potter’s Wheel”)

- How It Works: A CNC lathe spins the raw material while a computer-controlled tool cuts it into cylindrical shapes: EV motor shafts, aerospace fasteners, medical implant stems. Advanced CNC lathes (turn-mill centers) add milling capabilities—letting you cut slots or drill holes in the same setup.

- Example: A CNC lathe makes an EV motor shaft (φ20mm, 100mm long) in 3 minutes: it spins the steel stock, cuts the main diameter (±0.003mm), adds a chamfer (0.5×45°), and drills a 5mm hole in the end—all without stopping.

- Craftsman’s Insight: “CNC turning is all about balancing speed and precision. I once tried to turn a stainless steel shaft at 3000r/min—too fast, it vibrated, and the diameter was off. Slowed to 2000r/min, added more coolant—perfect. CNC gives you control, but you still need to understand the material’s limits.”

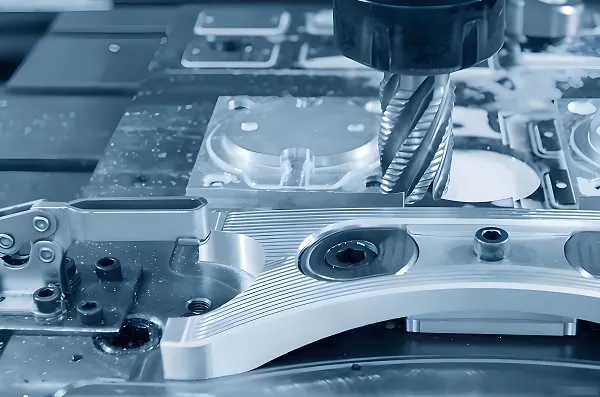

2. 5-Axis CNC Milling (For Complex 3D Components—The “Digital Sculptor”)

- How It Works: A 5-axis CNC mill moves the tool along X, Y, Z axes and tilts it around A (X-axis rotation) and B (Y-axis rotation) axes. This lets you cut complex shapes in one setup—no re-clamping, no alignment errors.

- Example: A 5-axis mill machines an aerospace turbine blade (titanium) in 15 minutes: it cuts the curved leading edge, mills internal cooling channels (1mm wide), and adds a porous surface for heat dissipation—all in one run.

- Craftsman’s Insight: “Re-clamping is the enemy of precision. I once made a turbine blade with manual milling—had to re-clamp it 3 times, and the final shape was off by 0.01mm. With 5-axis, it’s one setup, one program, zero deviation. It’s like carving a statue without moving the stone.”

3. CNC EDM (For Hard Materials—The “Digital Spark Cutter”)

- How It Works: CNC Electrical Discharge Machining (EDM) uses electrical sparks to erode hard materials (tungsten, tool steel) that CNC mills/lathes can’t cut. Wire EDM uses a thin copper wire (0.1mm) to cut complex shapes; sinker EDM uses a custom electrode to create internal cavities.

- Example: CNC wire EDM cuts a tool steel mold for EV battery covers—with tiny slots (0.2mm wide) and sharp corners (no rounded edges). No mill could cut those slots without breaking.

- Craftsman’s Insight: “EDM is CNC’s ‘secret weapon’ for hard materials. I once cut a tungsten aerospace component (HRC 65) with wire EDM—it took 2 hours, but the tolerance was ±0.001mm. A mill would have dulled 10 tools and still not gotten the shape right. EDM doesn’t ‘cut’—it ‘erodes’—and that’s why it works for the hardest stuff.”

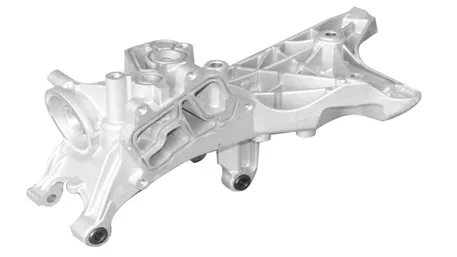

4. CNC Routing (For Large/Soft Components—The “Digital Carpenter”)

- How It Works: A CNC router uses a rotating spindle (similar to a mill) to cut large, soft materials: EV battery trays (aluminum sheets), plastic medical device housings, carbon fiber aerospace panels. It’s ideal for flat or slightly curved components that need large worktables (up to 4m×8m).

- Example: A CNC router cuts an EV battery tray (1.2m×0.6m, aluminum sheet) in 10 minutes: it cuts the outer shape, drills 20 mounting holes (±0.005mm alignment), and adds chamfers to avoid sharp edges.

- Craftsman’s Insight: “CNC routing is perfect for large components—manual routing would take hours and leave uneven edges. We made 100 EV battery trays last month with a CNC router—all the holes lined up, all the edges smooth. It’s like having a giant, precise pair of scissors for metal or plastic.”

Critical Applications: Where CNC Machined Components Shine

1. Electric Vehicle (EV) Industry (The “Mass-Precision Leader”)

- Key CNC Components: Motor shafts, battery trays, inverter housings, charging port brackets.

- Why CNC?: EVs need 1,000+ components that fit perfectly (to avoid short circuits or vibration) and are lightweight (to boost range). CNC delivers both: a CNC-machined aluminum battery tray is 30% lighter than a welded one, with holes aligned to ±0.005mm.

- Data Point: 95% of EV motor components are CNC-machined (Source: EV Manufacturing Trends 2025).

- Craftsman’s Insight: “I make CNC-machined inverter housings for EVs—they hold sensitive electronics, so the surface must be flat (Ra≤0.8μm) to seal properly. Manual machining would leave bumps; CNC leaves it smooth. One bad seal, and the inverter fails. CNC makes sure every housing seals right.”

2. Aerospace Industry (The “Extreme Precision Pioneer”)

- Key CNC Components: Turbine blades, landing gear parts, avionics housings, fasteners.

- Why CNC?: Aerospace components must withstand extreme conditions (600℃ engine heat, 30,000ft pressure) and be lightweight. 5-axis CNC machines make titanium turbine blades with internal cooling channels—something no other process can do.

- Example: A CNC-machined aerospace fastener (titanium, φ5mm) has a tolerance of ±0.001mm—if it’s too big, it won’t fit; too small, it will vibrate loose.

- Craftsman’s Insight: “Aerospace is ‘zero defect’—one bad component can bring down a plane. We test every CNC-machined turbine blade with X-ray and ultrasonic inspection. It’s time-consuming, but when I see a plane fly with our blades, I know it’s worth it.”

3. Medical Industry (The “Life-Saving Precision Expert”)

- Key CNC Components: Hip/knee implants (titanium), surgical robot arms, insulin pump housings (PEEK), dental crowns (zirconia).

- Why CNC?: Medical components need biocompatibility (no toxic materials), ultra-smooth surfaces (no tissue irritation), and tight tolerances (implants that fit bone perfectly). CNC machines cut titanium implants with Ra≤0.2μm surfaces—smooth enough to avoid inflammation.

- Example: A CNC-machined surgical robot joint (stainless steel) moves with 0.001mm precision—letting surgeons make incisions as small as 2mm.

- Craftsman’s Insight: “I once machined a titanium hip implant for a patient. The surgeon said it ‘integrated with the bone faster than any other implant’ because of the CNC-cut porous surface. That’s when CNC feels like more than a job—it feels like saving lives.”

4. Industrial Automation (The “Robotic Precision Backbone”)

- Key CNC Components: Robot arm joints, conveyor belt gears, sensor mounts, automated grippers.

- Why CNC?: Automation relies on components that move smoothly and repeatably. A CNC-machined robot arm joint (aluminum) has zero play—letting the robot pick up a 0.5mm electronic component without dropping it.

- Data Point: 90% of industrial robot components are CNC-machined (Source: Automation Technology Report 2025).

- Craftsman’s Insight: “We make CNC-machined grippers for a packaging robot—they need to gently hold eggs without breaking them. The gripper’s surface has tiny CNC-cut grooves (0.1mm deep) that create friction. Manual machining would never get those grooves consistent. CNC makes the robot reliable.”

Common Misconceptions: What People Get Wrong About CNC Machined Components

1. “CNC machined components are too expensive for small batches.”

- Reality: CNC is cost-effective for small batches (10–100 parts) because programs are reusable. Once you write a G-code for a component, you can run it again anytime—no need to retool. I once made 20 custom plastic sensor housings for a startup; the program took 1 hour to write, and the parts took 2 hours to make. Manual machining would have taken 8 hours.

- Fix: Think “program cost, not per-part cost.” Small batches benefit from CNC’s speed and precision—you pay for the program once, then run parts cheaply.

2. “CNC machines can make any shape—no need for design rules.”

- Reality: CNC has limits—you can’t cut a component with an internal cavity that’s unreachable by the tool (e.g., a closed box with no opening). Designing for CNC (DFM) is critical: add draft angles (1–3°) to avoid tool binding, use minimum wall thickness (1.5mm for aluminum), and avoid sharp internal corners (use 0.5mm radii).

- Example: A client once designed a plastic housing with a 0.8mm wall thickness—CNC cut it, but it cracked during testing. We redesigned it to 1.5mm, and it worked. CNC can’t fix bad design—only follow good design.

3. “CNC operation doesn’t need skill—just press ‘start’.”

- Reality: CNC operators need deep skill: they must understand G-code, adjust parameters for different materials, troubleshoot errors (e.g., tool breakage), and interpret blueprints. I once had a new operator press “start” on a titanium part without checking coolant levels—the tool overheated and broke. Skill turns CNC from a machine into a solution.

- Craftsman’s Insight: “Pressing ‘start’ is the easy part. The hard part is knowing when to stop—if the machine makes a strange noise, or the part looks off. Skill lets you catch mistakes before they become scrap.”

Q&A: Wisdom from the CNC Shop Floor

Q1: “I need 50 custom titanium components—should I use CNC turning or 5-axis milling?”

- My Answer: It depends on the shape:

-

- If it’s rotational (e.g., a shaft, fastener), use CNC turning (faster, cheaper).

-

- If it’s complex (e.g., a curved implant, angled bracket), use 5-axis milling (only way to get the shape).

Q2: “What’s the maximum precision I can get from CNC machined components?”

- My Answer: It depends on the machine and material:

-

- Standard CNC mills/lathes: ±0.005mm (good for EV parts, industrial components).

-

- High-precision CNC (with linear scales): ±0.001mm (for aerospace, medical parts).

-

- Titanium (harder material) holds tighter tolerances than aluminum (softer material).

Q3: “How do I choose between aluminum and titanium for my CNC component?”

- My Answer: Ask three questions:

-

- Weight matters? Aluminum is 50% lighter than titanium (good for EVs, aerospace).

-

- Strength/heat resistance needed? Titanium is stronger at high temperatures (good for engine parts, medical implants).

-

- Budget? Aluminum is 70% cheaper than titanium (good for cost-sensitive parts).

Q4: “Can CNC machined components be recycled?”

- My Answer: Yes—most CNC machined components are made of recyclable materials (aluminum, steel, titanium). The scrap from CNC cutting (chips, offcuts) is melted down and reused. We recycle 95% of our aluminum scrap—it’s good for the planet and reduces material costs.