In the intricate world of manufacturing, precision isn’t just a buzzword—it’s the foundation of reliable, high-performance products. From aerospace components to medical devices, precision machined parts are the unsung heroes that ensure everything fits, functions, and lasts. But what exactly are they, and why do they matter for your project? Let’s break down the technology, benefits, and real-world impact of precision machined parts, and how Xiamen Goldcattle’s 26 years of expertise can deliver the accuracy you need.

Defining Precision Machined Parts: Beyond Basic Manufacturing

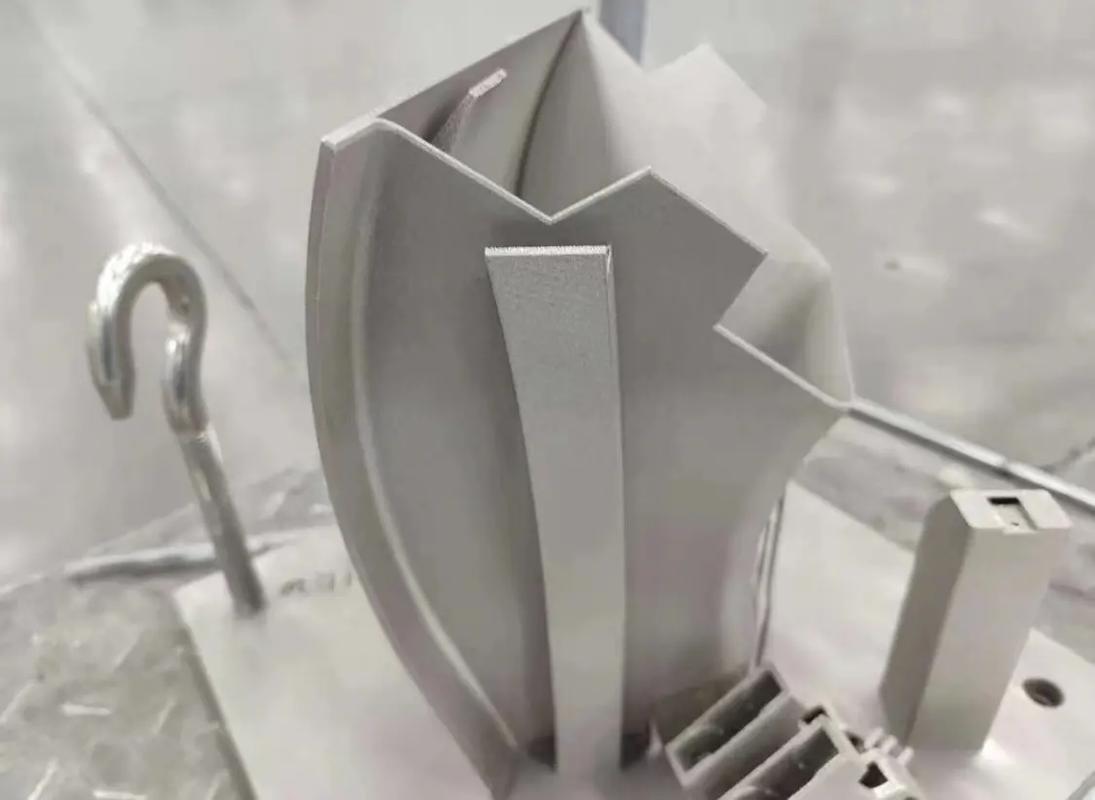

Precision machined parts are custom components crafted using advanced computer-controlled (CNC) machinery to achieve extremely tight tolerances and consistent quality. Unlike general machining, which focuses on basic shaping, precision machining prioritizes accuracy—often reaching tolerances as low as ±0.005mm, a level 1/20th the thickness of a human hair—to meet exact design specifications.

The process follows subtractive manufacturing principles: cutting, milling, turning, or drilling material from a solid block to create the final part. This method ensures dimensional repeatability across batches, with modern CNC systems maintaining positional accuracy within 0.001mm per axis. Such precision makes these parts indispensable for applications where even microscopic deviations could cause system failure.

Materials Matter: Choosing the Right Substance for Precision

The magic of precision machining lies not just in the equipment, but in how it handles diverse materials, each with unique machining characteristics:

- Metals: Aluminum (6061-T6), stainless steel (304/316), brass, and titanium are industry staples. Aluminum’s machinability rating of 100 (per the American Iron and Steel Institute scale) makes it 3x easier to machine than stainless steel, while titanium’s strength-to-weight ratio (4.5x stronger than steel at half the weight) suits aerospace demands.

- Plastics: ABS (machining tolerance ±0.02mm/mm), POM (low friction coefficient of 0.15), and acrylic (optical clarity >92%) offer versatility. Medical-grade plastics like PEEK maintain structural integrity at temperatures up to 260°C, critical for sterilization processes.

- Composites: Carbon fiber-reinforced polymers (CFRP) combine a tensile strength of 3,000 MPa with lightweight properties, reducing part weight by 40-60% compared to aluminum in automotive and robotics applications.

At Xiamen Goldcattle, our material database tracks over 50 engineering materials, with testing data on machinability, post-processing behavior, and environmental resistance to match your project’s exact needs.

How Precision Machining Works: The Process Behind the Perfection

Creating a precision machined part is a blend of technology, skill, and strict quality control. Here’s a data-backed look at our process:

1. Design & Engineering Review

Our team uses CAD software (SolidWorks, AutoCAD) to analyze 3D models, conducting tolerance stack-up analysis to identify potential fit issues. We optimize toolpaths using AI-driven simulation, reducing material waste by an average of 15% compared to traditional programming methods.

2. CNC Programming

Advanced CAM software converts designs into G-code with 0.0001mm step increments. For complex geometries, our 5-axis CNC systems use simultaneous multi-axis movement, achieving surface finishes as smooth as Ra 0.8μm—critical for fluid dynamics in hydraulic components.

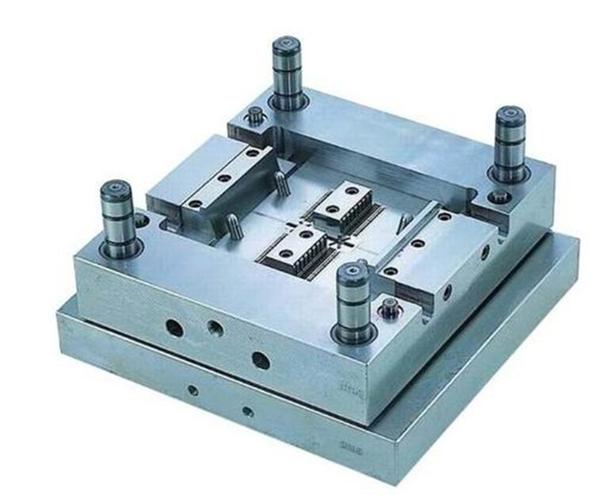

3. Machining with Advanced Equipment

Our facility operates 106 CNC machines, including 12 high-speed 5-axis mills (spindle speeds up to 20,000 RPM) and 8 precision lathes. These tools maintain thermal stability within ±0.5°C during operation, preventing dimensional shifts from heat expansion.

4. Rigorous Quality Inspection

Every part undergoes 3-stage inspection:

- In-process checks with laser micrometers (accuracy ±0.0005mm)

- Post-machining verification using coordinate measuring machines (CMMs) with 0.001mm volumetric accuracy

- Surface finish testing via profilometers to ensure Ra/Rz specifications

This process achieves a 99.7% first-pass yield rate, minimizing rework and delays.

Where Precision Machined Parts Make a Difference: Real-World Applications

Precision machined parts enable innovation across industries with measurable impact:

- Aerospace & Defense: Aircraft fuel system components require ±0.002mm tolerances to prevent leaks. Our machined aluminum brackets for a drone manufacturer reduced weight by 22% while increasing structural rigidity by 35%.

- Medical Devices: Surgical instrument components must meet ISO 13485 standards. We produced 500+ stainless steel forceps parts with 0.003mm tip alignment, passing all biocompatibility tests.

- Automotive: Engine valve lifters machined to Ra 0.4μm surface finish reduced friction by 18%, improving fuel efficiency by 3% in client tests.

- Electronics: Heat sink fins with 0.1mm wall thickness (machined from copper) improved thermal dissipation by 40% for a 5G router manufacturer.

Why Choose Xiamen Goldcattle for Your Precision Machined Parts?

With 26 years in the industry, we’ve honed our craft to deliver precision that matters. Here’s what sets us apart:

- Technical Expertise: Our 18 certified CNC programmers (with 10+ years average experience) specialize in complex geometries, achieving 98.5% on-time first-article inspection approval.

- Certified Quality: ISO 9001:2000, SGS, and CE certifications ensure compliance with international standards, with a documented 99.9% order accuracy rate over the past 5 years.

- Efficiency Metrics: Our streamlined workflow reduces lead times by 20% compared to industry averages—prototypes in 3–7 days, production runs of 10,000+ parts in 2–3 weeks.

- Material Mastery: We maintain 15+ material certifications (including AS9100 for aerospace, ISO 13485 for medical), with in-house material testing labs to verify tensile strength, hardness, and chemical resistance.

Frequently Asked Questions (FAQs)

- What tolerances can you achieve with precision machining?

Standard tolerances range from ±0.01mm to ±0.005mm, with specialized projects achieving ±0.002mm for critical components. Tolerance depends on material (e.g., aluminum vs. titanium) and part geometry.

- How does material choice affect machining precision?

Materials with higher hardness (like titanium, 30-35 HRC) require slower feed rates (50-100 mm/min) but maintain tighter tolerances, while softer materials (aluminum, 60-70 HB) allow faster speeds (300-500 mm/min) with excellent surface finish.

- What’s your capacity for production runs?

We handle volumes from 1 prototype to 100,000+ parts monthly. Our automated cells produce 5,000+ small components daily with consistent quality.

- How do you ensure quality across large batches?

We implement statistical process control (SPC), sampling 5% of each batch for CMM inspection and logging data in our quality management system. This ensures 99.7% conformity to specifications.

Got more questions about precision machined parts? Or ready to start your project? Leave a comment below with your design details, and our team will respond within 24 hours. Let’s build precision into your next innovation!