- Answer

Five common types of CNC machine tools include:

CNC milling machine: Milling planes, grooves, or complex curved surfaces through a rotating cutting tool.

CNC lathe: Clamping the workpiece for rotation and using a turning tool to cut cylindrical parts.

CNC machining center: Integrating multiple functions such as milling, drilling, and boring, with an automatic tool – changing device.

CNC grinding machine: Using a grinding wheel to grind the workpiece surface to achieve high – precision smoothness.

CNC laser cutting machine: Utilizing a laser beam to melt or vaporize materials, cutting thin plates or metal pipes. - Explanation

The CNC machine tool family is like a “combination of hardware stores in the industrial world”:

CNC milling machine: It’s like a “carving knife that can turn corners”, capable of “drawing” various planes or curved surfaces on materials (such as milling the tooth surface of a gear).

CNC lathe: Similar to a “rotating pencil sharpener”, it clamps a cylindrical material (such as an aluminum rod), rotates it while cutting, and produces pen – shaped parts.

Machining center: It’s like an “all – around Swiss Army knife”. It can both mill and drill, and can automatically change tools, completing complex parts in one go.

CNC grinding machine: Just like a “precision polisher”, it uses a grinding wheel to make the part surface as smooth as a mirror (such as parts of medical devices).

Laser cutting machine: It’s like a “lightsaber cutter”, quickly “cutting” out complex shapes of metal sheets with a laser beam (such as hollow decorative parts). - Problem Expansion

Core Functions and Application Scenarios of Various Machine Tools

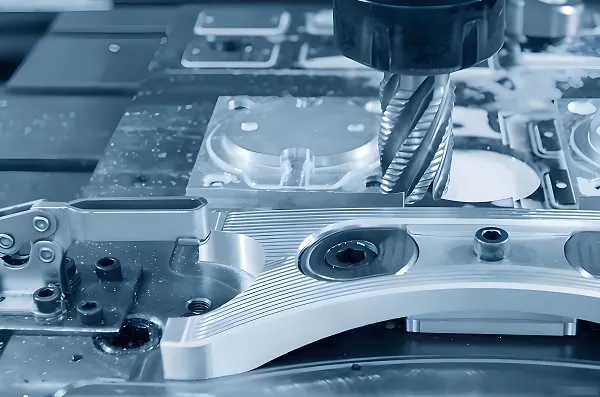

CNC milling machine (3 – axis / 5 – axis)

Features: A 3 – axis milling machine can process planes and simple curved surfaces, while a 5 – axis milling machine can rotate the cutting tool at multiple angles to handle complex structures such as impellers and aero – engine blades.

Applications: Machining the cavity of automotive molds, milling the aluminum – alloy frame of unmanned aerial vehicles.

CNC lathe

Features: The main motion is the rotation of the workpiece. It is suitable for processing axis – symmetric parts (such as shafts and discs), with an accuracy up to IT6 level (±0.01mm).

Applications: Producing motor shafts, bicycle frame tubes, and the valve cores of bathroom faucets.

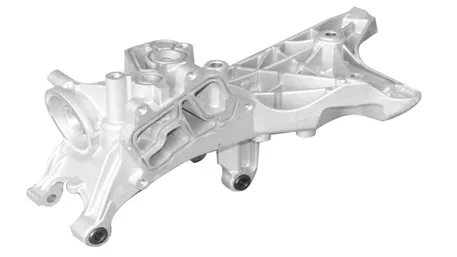

CNC machining center

Core advantages: Multiple processes (milling, drilling, tapping) can be completed in one clamping, reducing the error of manual tool – changing. For example, when machining a transmission housing, it can continuously complete milling the plane → drilling → boring → chamfering, with an efficiency 3 times higher than that of traditional machine tools.

Typical scenarios: Mass – producing mobile phone mid – frames (requiring integrated milling of curved surfaces + drilling + polishing).

CNC grinding machine (surface grinding / cylindrical grinding)

Accuracy level: The surface roughness can reach Ra 0.1μm (mirror level), used for the final processing of precision parts (such as gauge blocks and guide rails).

Medical applications: Grinding the surface of artificial joints to ensure fit and wear resistance (error < 0.005mm).

CNC laser cutting machine

Technological breakthroughs: Fiber – optic laser cutting machines can cut 20mm – thick steel plates, with a speed 5 times that of traditional tools and minimal thermal deformation.

Creative scenarios: Cutting hollow patterns in sheet metal processing (such as elevator panel decorations), and cutting lithium – battery electrode sheets in the new energy field.