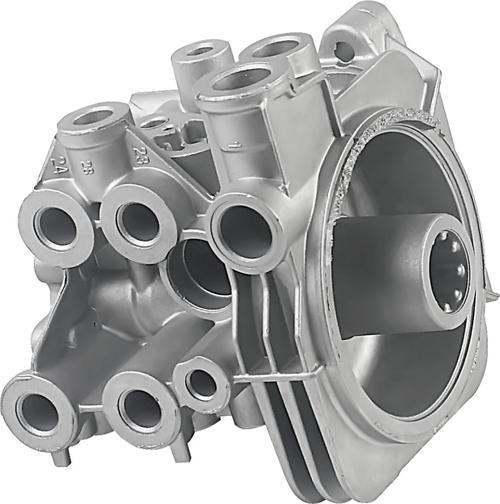

Die casting is a popular metal forming process for mass-producing complex parts (e.g., automotive components, electronics housings) due to its high efficiency and precision. However, it’s not a one-size-fits-all solution—several inherent limitations can impact cost, design flexibility, and application suitability. Below are the 6 core disadvantages of die casting, along with insights into why they occur and how to mitigate their effects.

1. High Initial Investment & Tooling Costs

The biggest barrier to die casting is its steep upfront cost, primarily driven by custom die (mold) manufacturing and specialized equipment.

- Why it’s a problem: Dies are typically made from high-strength steel (e.g., H13 tool steel) to withstand repeated high-pressure (1,000–15,000 psi) and high-temperature (up to 700°C for aluminum) cycles. A single complex die can cost (10,000–)100,000+ depending on size, cavity count, and precision. Additionally, die casting machines (hot chamber for zinc, cold chamber for aluminum/magnesium) require significant capital expenditure ((50,000–)500,000+).

- Impact: Small-batch production (e.g., <10,000 units) often cannot justify these costs—die expenses may outweigh savings from fast production speeds.

-

- For low volumes, use prototype dies (simpler, lower-cost materials like P20 steel) or share die costs with similar projects.

-

- Opt for multi-cavity dies if producing high volumes (spreads tooling costs across more parts).

2. Limited Material Options (High-Melting-point Metals Are Excluded)

Die casting works best with non-ferrous metals that have low melting points, which restricts its use for high-strength or high-temperature applications.

- Why it’s a problem: The process relies on forcing molten metal into tight die cavities—metals with high melting points (e.g., steel, iron, titanium, nickel alloys) would damage steel dies or require impractical heating/cooling systems.

- Commonly compatible metals: Zinc, aluminum, magnesium, and copper alloys (e.g., Zamak 3, A380 aluminum).

- Impact: Industries like aerospace (needing titanium parts) or heavy machinery (needing steel components) cannot use die casting for critical parts.

-

- Combine die casting with other processes (e.g., die-cast an aluminum housing, then assemble with steel inserts for strength).

-

- For high-temperature needs, switch to investment casting (suitable for stainless steel) or sand casting (for iron).

3. Design Limitations: Thin Walls, Deep Cavities, and Complex Geometries

While die casting excels at complex shapes, it has strict constraints on wall thickness, depth, and undercuts that can limit design freedom.

-

- Thin walls: Molten metal may not flow evenly into walls thinner than 0.8mm (for aluminum) or 0.5mm (for zinc), leading to incomplete filling or weak spots.

-

- Deep cavities: Cavities deeper than 4x their width risk trapped air (causing porosity) or difficulty ejecting parts from the die.

-

- Undercuts: Features like grooves or tabs that face the die’s ejection direction require complex, expensive slides or retractable cores—adding tooling costs and production time.

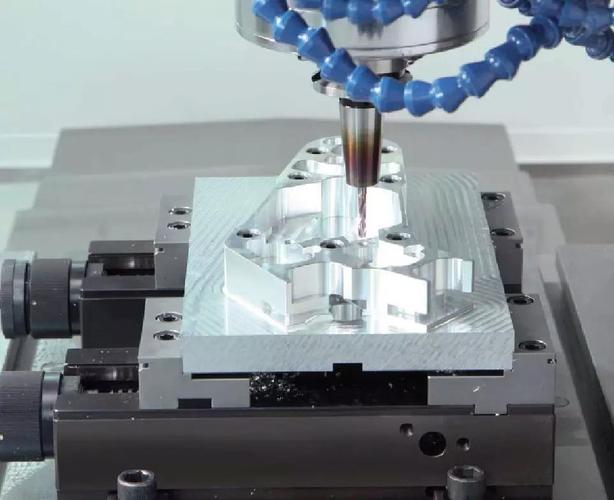

- Impact: Parts with intricate details (e.g., micro-channels, ultra-thin brackets) may require secondary machining, increasing lead times and costs.

-

- Work with die casters early in the design phase to follow DFM (Design for Manufacturability) rules (e.g., minimum wall thickness, draft angles of 1–3° for easy ejection).

-

- Use secondary machining (e.g., CNC milling) for undercuts or thin features after casting.

4. Porosity and Surface Defects

Die-cast parts often suffer from internal porosity (tiny air bubbles) or surface flaws, which can compromise strength and aesthetics.

-

- Porosity: Molten metal traps air as it fills the die cavity—especially with high-pressure injection or improper die venting. Porosity weakens parts under stress (e.g., in structural automotive components) and makes them unsuitable for pressure-tight applications (e.g., hydraulic valves).

-

- Surface defects: Common issues include flash (excess metal along die seams), sink marks (indentations from uneven cooling), and die lines (scratches from die surfaces).

- Impact: Defective parts may require rework (e.g., grinding flash) or rejection, increasing waste and costs. Porous parts also cannot be heat-treated (heat causes bubbles to expand, ruining the part).

-

- Optimize die design with proper venting (small channels to release air) and gate placement (controls metal flow).

-

- Use vacuum die casting (removes air from the die before injection) to reduce porosity by up to 80%.

-

- Apply post-processing: Hot isostatic pressing (HIP) compacts pores, or coating/painting hides surface flaws.

5. Dependency on High Production Volumes

Die casting is only cost-effective for large-batch production—it struggles to compete for small runs or custom parts.

- Why it’s a problem: Tooling and setup costs are amortized over the number of parts produced. For small volumes (e.g., 500–5,000 units), the per-unit cost remains high (often 2–5x more than sand casting or 3D printing).

- Impact: Startups, prototype developers, or businesses needing custom parts cannot leverage die casting’s speed without overspending.

-

- For prototypes: Use 3D printing (e.g., SLM for metal) or sand casting (lower tooling costs) to test designs before investing in dies.

-

- For mid-volume runs: Explore semi-permanent mold casting (balances cost between die casting and sand casting).

6. High Post-Processing Requirements

Die-cast parts rarely come “ready-to-use”—most require secondary operations to meet quality or assembly standards, adding time and cost.

- Common post-processing steps:

-

- Trimming: Removing flash or excess metal from gates/runners (done with trim presses or CNC routers).

-

- Machining: Refining critical features (e.g., holes, threads) to meet tight tolerances (die casting alone typically achieves ±0.1mm tolerance).

-

- Finishing: Polishing, plating (e.g., chrome for aesthetics), or coating (e.g., anodizing for corrosion resistance).

- Impact: Post-processing can add 10–30% to the total part cost and extend lead times by 1–2 weeks.

-

- Design parts to minimize post-processing (e.g., integrate threads into the die instead of machining them).

-

- Partner with die casters that offer one-stop services (casting + trimming + finishing) to reduce logistics and costs.

When Should You Avoid Die Casting?

Die casting is not ideal if:

- You need small production runs (<10,000 units).

- Your part requires high-melting-point metals (e.g., steel) or extreme strength (e.g., load-bearing aerospace components).

- Your design has ultra-thin walls, deep undercuts, or pressure-tight requirements (without post-processing).

Final Takeaway

While die casting is efficient for mass-produced, non-ferrous parts, its disadvantages—high upfront costs, material limits, and design constraints—require careful evaluation. The key to success is aligning your project’s volume, material needs, and design goals with the process’s strengths. For uncertainty, consult a die casting specialist to conduct a feasibility analysis (e.g., cost vs. volume, design optimization) before committing to tooling.

Got questions about die casting for your specific project? Leave a comment below, and we’ll help you assess if it’s the right fit!