Ever wondered how a block of metal transforms into a perfectly shaped component for an airplane, medical device, or electric car? The answer lies in the CNC process—a series of carefully orchestrated steps that blend technology, expertise, and precision. CNC (Computer Numerical Control) machining isn’t just about pushing a button; it’s a structured workflow that ensures every part meets exact specifications. At Goldcattle, with 26 years of mastering this craft, we’ve refined these steps to deliver consistency and quality across industries. Let’s break down the key stages of the CNC process, how they work, and why Goldcattle stands out in executing them flawlessly.

The Core of the CNC Process: Why Steps Matter

The CNC process is built on order—each step depends on the one before it, and skipping or rushing any stage risks errors, delays, or subpar parts. Whether producing a single prototype or 10,000 production parts, following these steps ensures accuracy (tolerances as tight as ±0.001mm), repeatability, and efficiency. Now, let’s walk through each stage.

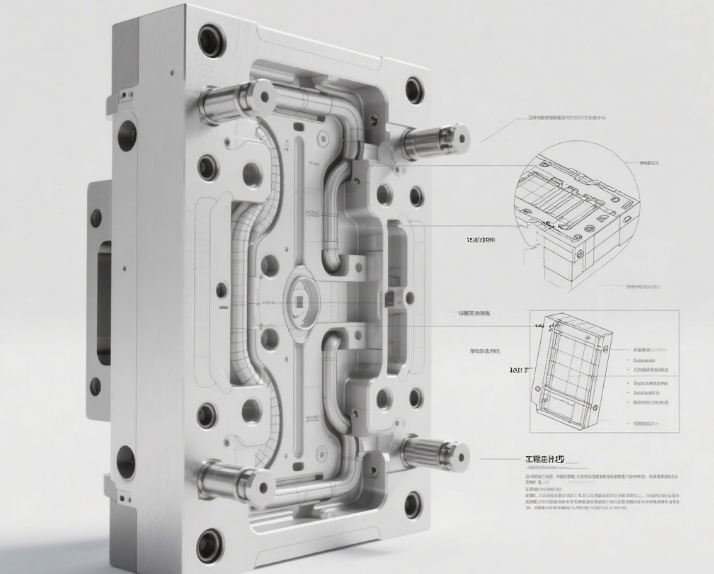

Step 1: Design & DFM Analysis – Laying the Foundation

Every CNC project starts with a design. This step involves:

- CAD Modeling: Engineers create 3D models using software like SolidWorks or AutoCAD, defining dimensions, features (holes, slots, curves), and tolerances. For example, a medical bracket might require a 2mm hole with ±0.01mm tolerance to fit a screw perfectly.

- DFM Review: Before machining, Goldcattle’s team conducts Design for Manufacturability (DFM) analysis. We check for potential issues—like a 0.5mm thin wall that might warp during machining—and suggest tweaks (e.g., increasing thickness to 1mm) to improve quality and reduce costs .

Goldcattle Insight: Our DFM experts save clients an average of 15% in production costs by optimizing designs upfront. A recent aerospace client’s turbine part design was adjusted to reduce tool changes, cutting production time by 20%.

Step 2: Material Selection & Preparation – Choosing the Right Foundation

The right material makes or breaks a part. This step involves:

- Material Matching: Selecting materials based on the part’s purpose. For example:

-

- Aluminum 6061 for lightweight aerospace parts (tensile strength 310 MPa)

-

- Stainless Steel 316 for corrosion-resistant medical tools

-

- Brass C36000 for high-conductivity electrical connectors

- Material Inspection: Raw materials (bars, sheets, blocks) undergo checks—like ultrasonic testing for hidden defects—to ensure they meet quality standards. Goldcattle sources materials from certified suppliers, with traceability documents for every batch .

- Cutting to Size: Large materials are cut into workable blanks, reducing waste and making handling easier during machining.

Step 3: CNC Programming – Translating Design to Machine Code

CNC machines don’t “read” CAD files directly—they need code. This step includes:

- CAM Software Conversion: Engineers use CAM (Computer-Aided Manufacturing) software to convert CAD models into G-code or M-code—the language CNC machines understand. This code defines tool paths, cutting speeds (3,000–15,000 RPM for metals), and feed rates.

- Tool Path Optimization: Programmers ensure tools move efficiently to minimize idle time. For complex 5-axis parts, paths are simulated to avoid collisions between the tool and workpiece .

Goldcattle Edge: Our master programmers use advanced CAM software to program 5-axis CNC machines, reducing setup time by 30% compared to traditional 3-axis programming.

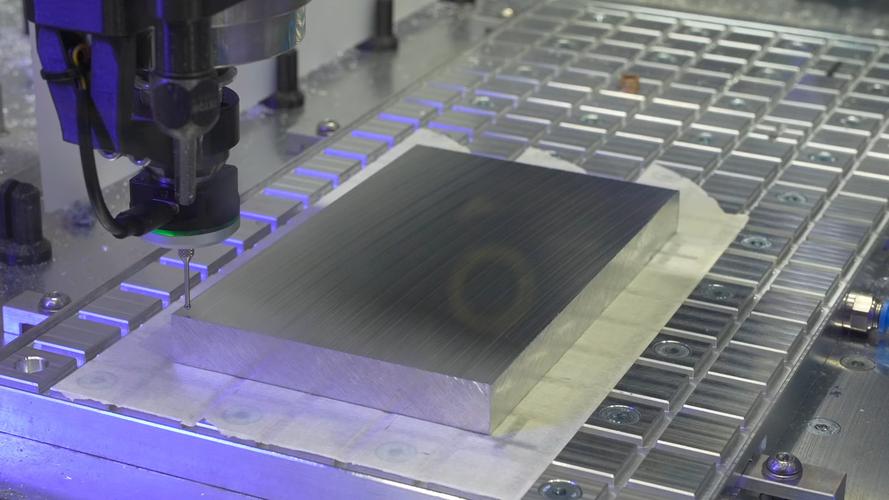

Step 4: Machining Execution – Turning Design into Reality

This is where the magic happens. The CNC machine follows the programmed code to shape the material:

- Setup: The blank is clamped into the machine (vices, chucks, or custom fixtures) to prevent movement during cutting. For large parts, Goldcattle uses rotary tables or 5-axis setups to access all sides in one run.

- Cutting: Tools (carbide, diamond, or ceramic) remove material layer by layer. Mills create flat surfaces or complex 3D shapes; lathes spin the workpiece to craft cylindrical parts like shafts. Our 5-axis machines handle geometries that would require 3–4 setups on older equipment .

- Real-Time Monitoring: Operators oversee the process, checking for tool wear or anomalies. Goldcattle’s machines have sensors that alert operators to issues like excessive vibration, preventing defects.

Step 5: Quality Inspection – Ensuring Perfection

No part leaves the shop without rigorous checks:

- Dimensional Testing: Using tools like micrometers, calipers, and Coordinate Measuring Machines (CMMs) to verify dimensions. A CMM can measure 500+ points on a part with ±0.0005mm accuracy .

- Surface Finish Checks: Instruments like profilometers measure roughness (Ra values as low as 0.02μm for optical parts).

- Functional Testing: For critical parts (e.g., aerospace brackets), load or pressure tests ensure they perform under stress.

Goldcattle Standard: We 实行 100% inspection for medical and aerospace parts, with digital reports stored for traceability—meeting ISO 9001 and AS9100 standards.

Step 6: Post-Processing & Finishing – The Final Touch

Parts often need extra steps to meet performance or aesthetic needs:

- Deburring: Removing sharp edges to prevent injury or wear.

- Surface Treatments: Anodizing (for aluminum corrosion resistance), plating (chrome for durability), or passivation (for stainless steel).

- Assembly: For multi-part projects, components are assembled to ensure fit.

A recent automotive client’s aluminum parts received anodizing (thickness 10–15μm) to withstand road salt and humidity, extending their lifespan by 3 years.

Why Goldcattle’s CNC Process Stands Out

- 26 Years of Expertise: Our team knows how to optimize each step, from design to finishing, to deliver parts that exceed expectations.

- Advanced Equipment: 5-axis mills, Swiss-type lathes, and automated inspection tools handle complexities other shops can’t.

- Flexibility: We adapt the process for small batches (10 parts) or large runs (100,000+), maintaining consistency at every scale.

FAQs About the CNC Process

Q: How long does the CNC process take for a custom part?

A: It depends on complexity. Prototypes with simple designs take 1–3 days; complex 5-axis parts or large batches take 2–6 weeks. Goldcattle offers rush options for urgent projects .

Q: Can the process handle different materials?

A: Yes! We machine metals, plastics, and composites. The steps adjust slightly—e.g., slower cutting speeds for titanium vs. aluminum—to ensure quality.

Q: What if my design needs changes mid-process?

A: Our team works with you to update CAD models and reprogram machines, minimizing delays. We prioritize communication to keep projects on track.

Q: Do you offer design help if I don’t have a CAD file?

A: Absolutely! Goldcattle’s engineers can create 3D models from sketches or specifications, including DFM feedback to optimize your part.

Q: How do you ensure consistency across large batches?

A: We use automated tool changers, SPC (Statistical Process Control), and regular machine calibration to keep variation below ±0.001mm .

Ready to Start Your CNC Project?

The CNC process is a blend of science, skill, and technology—and Goldcattle has mastered every step to deliver precision parts that power your success. Whether you need a prototype or mass production, we’re with you from design to delivery.

Got questions about your specific project? Share your requirements below, and our CNC experts will guide you through the process!