Answer

To start metal stamping, you need:

- Equipment: Press machine (mechanical/hydraulic) and stamping dies;

- Materials: Metal sheets (e.g., carbon steel, aluminum alloy);

- Auxiliary tools: Feeder, lubricants, measuring gauges;

- Workspace: Load-bearing floor (presses can weigh tons) and safety protections.

Expansion

1. Core Equipment Selection

-

Press Types:

- Mechanical presses: Suitable for medium-speed stamping (100–300 strokes/min), 30–2,000 tons, ideal for automotive sheet metal (e.g., door panels).

- Hydraulic presses: Low-speed high-pressure (20–50 strokes/min), 500–5,000 tons, for thick plate forming (e.g., construction machinery bases).

- Servo presses: High-precision control (adjustable speed/pressure), for micro-stamping of electronic components (e.g., 0.1mm copper foil forming).

-

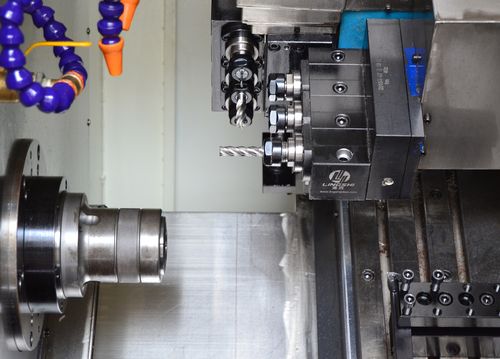

Die Composition:

- Upper/lower dies: Made of Cr12MoV tool steel (HRC58–62), requiring heat treatment for wear resistance;

- Guiding mechanism: Guide pillars/sleeves (clearance ≤0.02mm) to prevent die misalignment;

- Unloading device: Elastic stripper plate (prevents scrap adhesion).

2. Materials and Pretreatment

-

Common Metals:

Material Type Thickness Range Typical Applications Low-carbon steel (Q235) 0.5–4mm Brackets, structural parts Aluminum alloy (5052) 0.3–2mm Phone casings, heat sinks Stainless steel (304) 0.1–3mm Kitchenware, medical casings -

Pretreatment Requirements:

- Sheet flatness: Warpage ≤1mm/m (to avoid feeding jams);

- Surface cleanliness: Degreasing (stamping oil residue affects plating), burrs ≤0.05mm.

3. Auxiliary System Configuration

-

Feeding Automation:

- Roller feeders: Suitable for regular sheets (10–50 strokes/min);

- Robotic feeders: For multi-stage progressive dies (e.g., continuous stamping of terminals).

-

Lubrication & Safety:

- Lubricants: Extreme pressure emulsions (for thick plates) or solid lubricants (stainless steel anti-sticking);

- Safety devices: Photoelectric protection (prevents finger entry) and emergency stops (response time <0.1s).

4. Cost and Capacity Planning

-

Initial Investment:

- Small production line (30-ton press + simple die): ~$28,000–$70,000;

- Automotive-grade line (800-ton servo press + progressive die): $1.4M–$4.2M.

-

Capacity Calculation:

- Single-operation die: 50–200 parts/hour (e.g., simple punching);

- Progressive die: 500–1,500 parts/hour (e.g., continuous drawing).

5. Compliance and Quality Control

-

Industry Standards:

- Dimensional tolerance: Follow ISO 2768-mk (medium precision), custom tolerances for precision parts (e.g., ±0.03mm);

- Safety certifications: CE (EN 693 for presses), OSHA (workshop safety regulations).

-

Testing Tools:

- Routine: Calipers (0.01mm accuracy), projectors (contour inspection);

- Advanced: Coordinate measuring machines (CMM, 0.005mm accuracy) for aerospace parts.

6. Typical Startup Process

- Requirement analysis: Confirm batch size (e.g., 100,000 pieces), material (SPCC cold-rolled steel), precision (±0.1mm);

- Die design: 3D modeling (UG/NX) → die factory machining (4–8 weeks);

- Tool trial and debugging: First-piece inspection (dimensions/burrs) → die optimization (adjust punch-die clearance);

- Mass production: Set stamping parameters (150 strokes/min, 80-ton pressure) → first inspection + patrol inspection (every 2 hours).

Notes:

- For low-volume trials (500 pieces), use Simple mold (zinc alloy dies, 70% cheaper than steel);

- Environmental requirements: Stamping oils must meet VOCs standards, and waste should be sorted (metal recycling rate ≥95%).