CNC is the abbreviation of Computer Numerical Control. Its core is to automatically control machining equipment through computer programs, achieving high – precision and high – efficiency production processes.

I. Basic Concepts of CNC Machining

CNC machining is a technology that uses a digital control system to automatically control machine tools. Through pre – written numerical control programs (such as G – code and M – code), parameters such as the tool path, cutting speed, and feed rate of the machine tool are controlled to achieve precision machining of materials such as metals, plastics, and wood. CNC machine tools include various types such as CNC milling machines, CNC lathes, and CNC grinders, and can complete multiple machining tasks such as cutting, drilling, milling, and grinding.

II. Steps for Machining Parts by CNC

Analyze the part drawing to understand the general situation of the workpiece (geometric shape, workpiece material, process requirements, etc.).

Determine the CNC machining process of the part (machining content, machining route).

Conduct necessary numerical calculations (coordinate calculations of base points and nodes).

Compile the program list (it may vary for different machine tools, follow the user manual).

Check the program (input the program into the machine tool and perform graphic simulation to verify the correctness of programming).

Machine the workpiece (good process control can save time and improve machining quality).

Accept the workpiece and analyze quality errors (inspect the workpiece. If it is qualified, it proceeds to the next process. If unqualified, find out the reasons for errors and corrective methods through quality analysis).

III. Overview of CNC Production

Output Suitability: Suitable for both single – piece and large – batch production.

Quality: High surface quality, determined by the grinding and polishing processes in CNC.

Speed: Fast single – piece forming speed, specifically determined by the finished product size and the number of CNC operation steps set.

Applicable Materials: Basically suitable for all materials, such as plastics, metals, wood, glass, ceramics, and synthetic materials.

Design Considerations:

The number of axes of the CNC determines the shape of the finished product. For example, a lathe can only perform 2 – axis cutting (2 axes: x and y directions), while a milling machine can perform 5 – axis forming (5 axes: x, y, z directions plus 2 rotation axes).

CNC can directly import CAD data into the workbench, has strong material adaptability, and low cost. Therefore, it is often used by designers to make product prototypes, which is an indispensable part of the transition from design to production.

Whether the product shape is simple or complex, the CNC process treats them as multiple connectable sequential points for machining. You can join QQ group 304214709 to get UG learning materials and courses if you want to learn UG programming, providing unlimited design possibilities.

The cost of the CNC process is generally converted according to the unit time of finished product production.

IV. Detailed Explanation of the CNC Process

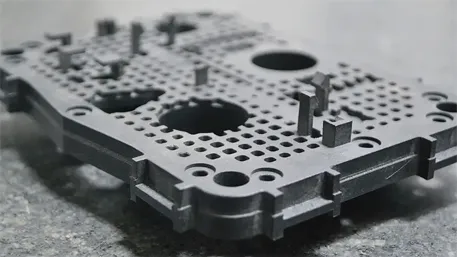

Type 1: 3 – axis CNC: The tool head can move on the horizontal x, y axes and the vertical z – axis. The forming process is completed by switching multiple tool heads, such as slot drills, taper drills, flute drills, and ball – nose end mills.

Type 2: 5 – axis CNC: The tool head can move on the horizontal x, y, z axes and 2 rotation axes. The forming process is completed by flexible cutting in multiple directions with a single tool head.

V. What is CNC Programming

CNC programming belongs to the field of CNC machining. It is divided into manual programming and computer – aided programming. If it is only simple planar machining and machining of regular angles (such as 90°, 45°, 30°, 60°), manual programming can be used. For machining complex curved surfaces, it depends on the computer.

Computer – aided programming depends on various programming software (such as UG, CAXA, PM, etc.).