In the context of cutting, CNC stands for Computer Numerical Control—a technology that uses computer programs to automate and precision-control cutting tools (e.g., lasers, plasma torches, routers, or saws) to shape materials like metal, wood, plastic, or fabric.

How does CNC work in cutting applications?

In cutting, CNC transforms digital designs into precise physical cuts through a structured process:

- Digital design: A 2D or 3D model of the desired shape is created using CAD (Computer-Aided Design) software.

- Programming: CAM (Computer-Aided Manufacturing) software converts the design into G-code, a numerical language that specifies cutting paths, tool speed, and feed rate.

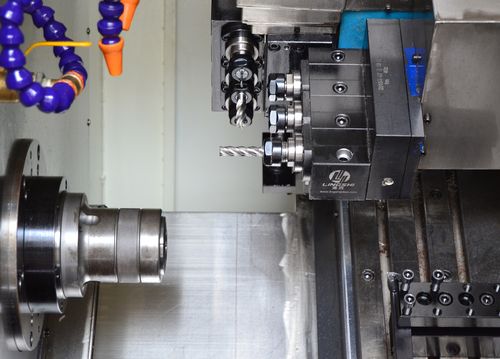

- Automated cutting: The CNC controller interprets the G-code, guiding the cutting tool (e.g., a laser beam or router bit) along the programmed path. Movements are precise, with tolerances as tight as ±0.001 inches, ensuring consistent cuts across multiple workpieces.

What makes CNC cutting different from manual cutting?

- Precision: CNC cutting follows digital coordinates, eliminating human error from manual guiding of tools (e.g., hand saws or plasma cutters). This is critical for complex shapes or tight tolerances.

- Automation: Once programmed, CNC machines run unattended, enabling 24/7 operation and reducing labor costs.

- Versatility: A single CNC machine can switch between cutting materials (e.g., steel, plywood, acrylic) by adjusting tools and parameters, unlike manual tools limited to specific materials.

Common CNC cutting technologies

In cutting, CNC powers various tools, each suited to specific materials:

- CNC laser cutting: Uses a high-energy laser beam to melt or vaporize materials (e.g., metal sheets, plastics). Ideal for intricate designs with fine edges.

- CNC plasma cutting: Uses ionized gas (plasma) to cut thick metals (e.g., steel, aluminum) quickly, often in industrial fabrication.

- CNC router cutting: Employs rotating bits to carve or cut wood, plastic, or soft metals, common in sign-making or furniture production.

- CNC waterjet cutting: Uses high-pressure water (mixed with abrasives) to cut heat-sensitive materials (e.g., glass, stone) without thermal damage.

Why is CNC essential in cutting?

In cutting applications, CNC ensures repeatability (identical parts from the same program), efficiency (faster cycle times than manual cutting), and complexity (ability to cut shapes with curves, angles, or nested patterns that manual methods can’t replicate). It’s widely used in industries like automotive (cutting metal panels), aerospace (precision parts), and construction (custom metal components).

Conclusion

In cutting, CNC stands for Computer Numerical Control—a technology that automates cutting tools via digital programs to achieve precise, consistent, and efficient material removal. By replacing manual tool control with computer-guided movements, CNC revolutionizes cutting processes across materials and industries, balancing accuracy and productivity.