3D printing, also known as additive manufacturing technology, is an advanced manufacturing technique that builds three-dimensional objects by adding material layer by layer. It stacks materials layer by layer based on a computer-generated three-dimensional model, ultimately forming a complete solid object. This technology is widely used in several fields with its unique advantages, including manufacturing, medical, aerospace, and art production.

1. Principle of 3D printing technology

3D printing works by cutting a digital model into multiple thin slices and then printing these slices layer by layer, stacking them one on top of the other to eventually form a complete solid object. In a 3D printer, the print material is heated to its melting point or otherwise processed into a flowable state and then ejected or deposited layer by layer through a nozzle following a preset path. As each layer is completed, the printing platform is lowered or the nozzle is raised in order to begin the next layer. This process is repeated until the entire object is completely fabricated.

2. 3D printed product customization

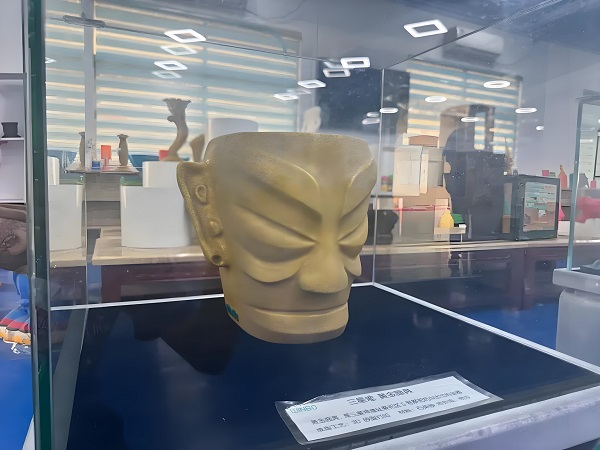

One of the biggest advantages of 3D printing technology is the ability to achieve highly personalized product customization. With CAD (Computer Aided Design) software, designers can create 3D models of any shape and size, without having to consider the mold or tooling limitations of traditional manufacturing. This ability allows consumers to customize products based on their needs and preferences, such as customized jewelry, shoes, eyewear, toys, and more. In addition, 3D printing can be used for rapid prototyping to help designers validate designs in the early stages of product development, reducing design cycles and costs.

3. Introduction to 3D printing materials

There are a variety of 3D printing materials, each with its own unique characteristics and application scenarios. The following are some common 3D printing materials and their characteristics:

Resin (Resin): commonly used in SLA (Stereo Light Curing) and DLP (Digital Light Processing) technology, with high precision and smooth surface, but the material cost is high and easy to brittle.

ABS resin (Acrylonitrile Butadiene Styrene): Used through FDM (Fused Deposition Molding) technology, relatively low price, a variety of materials, but lower precision and surface roughness.

Nylon: Commonly used in SLS (Selective Laser Sintering) technology, high strength and no need for support structures, but equipment is expensive and may generate dust.

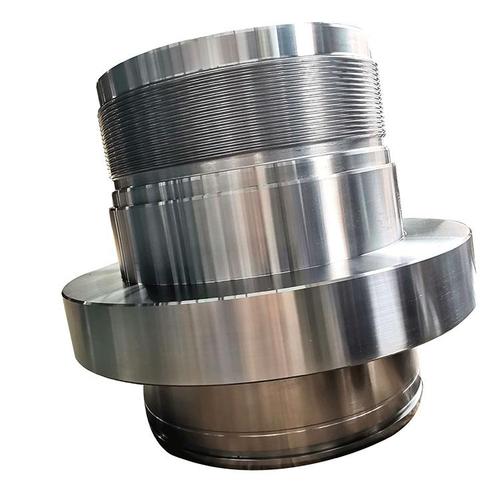

Metals (e.g. stainless steel, aluminum, titanium alloys): achieved through special 3D printing techniques (e.g. laser sintering or powder bed fusion), high strength and corrosion resistance, but costly and complicated to handle.

Rubber (Rubber): such as TPU (thermoplastic polyurethane), with good elasticity and abrasion resistance, suitable for printing products that require flexibility.

4. 3D printing product characteristics

3D printed products have a variety of unique characteristics, the following are a few aspects of the data show:

Design Freedom: 3D printing technology can realize the design of almost any complex shape, breaking the shape limitations of traditional manufacturing methods. Designers can take full advantage of the power of CAD software to create designs like never before.

Personalization: Due to 3D printing’s highly personalized customization capabilities, products can be customized to meet the individual needs of different consumers.

Reduce Waste: Traditional manufacturing methods usually require large amounts of raw materials and cutting processes, generating large amounts of waste. 3D printing technology, on the other hand, greatly reduces waste and waste of resources by adding materials layer by layer.

Short production cycle: 3D printing technology can directly transform a design into a physical product, eliminating multiple steps in traditional manufacturing and significantly shortening the production cycle.

Manufacturing Costs: Although the initial investment in 3D printer equipment and materials is relatively high, it can significantly reduce manufacturing costs when it comes to small batch production and customized manufacturing, especially in terms of reducing inventory risk and labor costs.

3D Printing FAQ

Q: Can ordinary people play with 3D printing?

A: Yes, ordinary people can play with 3D printing. As the technology becomes more popular and less expensive, more and more consumer-grade 3D printers are entering the market, making it easy for ordinary people to own and use 3D printers. With simple learning and practice, ordinary people can create a variety of interesting and useful items.

Q: What types of products can be made with 3D printing?

A: 3D printing technology can produce almost any type of three-dimensional object, including but not limited to household items, tools, artwork, medical devices, automotive parts, and more. As long as a 3D model can be designed and the right printing materials and technology are selected, it can be realized through 3D printing.

Q: What is the accuracy and surface quality of 3D printing?

A: The precision and surface quality of 3D printing depends on the technology and materials used. For example, SLA and DLP technologies can achieve high precision and smooth surface quality, while FDM technologies may produce lower precision and rough surfaces. In addition, post-processing steps (e.g. sanding, polishing, etc.) can further improve the surface quality of the product.

Q: What is the cost of 3D printing?

A: The cost of 3D printing varies by material, technology, and scale of production. For individuals and small businesses, consumer-grade 3D printers are relatively low cost and easy to operate. However, for application scenarios where mass production and high precision are required, more expensive equipment and materials may be needed. Overall, the cost of 3D printing is gradually decreasing as the technology continues to evolve and the market expands.