Precision Casting: The Complete Guide to Investment Casting Technology

Everything you need to know about precision casting processes, materials, applications, and how it compares to other manufacturing technologies

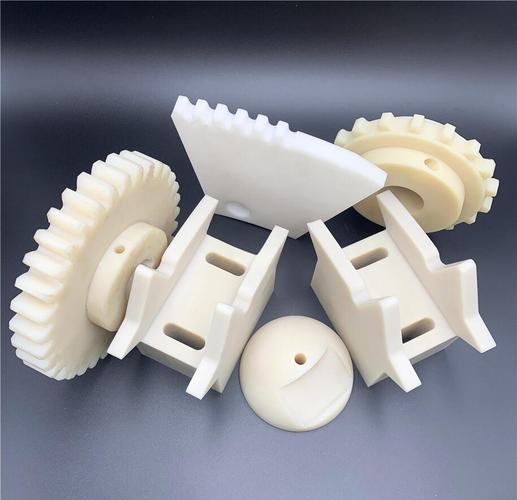

What is Precision Casting? I’ll Explain It Simply

Precision cast metal components with complex geometries and high dimensional accuracy

I’ve been working in precision manufacturing for over 15 years, and let me tell you, precision casting (also called investment casting or lost-wax casting) is one of the most versatile manufacturing processes out there. It’s a technique that lets you create complex metal parts with incredible accuracy, and it’s been around for thousands of years – yes, even the ancient Egyptians used similar methods!

Here’s how it works in simple terms. You start by making a wax pattern of the part you want to create. Then you coat this wax pattern with a ceramic material to create a shell. Once the ceramic shell hardens, you melt out the wax, leaving a perfect cavity. You pour molten metal into this cavity, let it cool, break away the ceramic shell, and you’ve got your finished part.

Why I Love Precision Casting

“What impresses me most is the design freedom it offers. You can create intricate internal channels, complex geometries, and thin walls that would be impossible or extremely expensive with other methods like CNC machining. It’s like sculpting with metal, but with industrial precision.”

The Complete Precision Casting Process: Step-by-Step

Let me walk you through the entire process from start to finish. I’ve done this hundreds of times, so I know every detail and what can go wrong at each stage.

Step 1: Pattern Making

Complex precision cast component showing the intricate details achievable with investment casting

This is where it all begins. We create an exact wax replica of the final part. For small production runs, we might use 3D printed patterns, but for larger volumes, we use injection molding to create wax patterns from metal molds.

I always say the pattern is the most critical part – if your pattern isn’t perfect, your final part won’t be either.

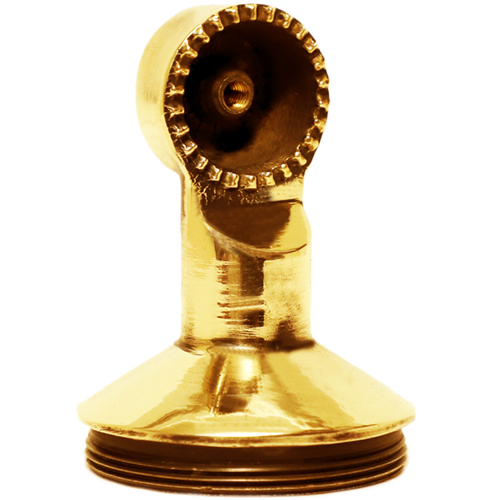

Step 2: Assembly and Gating

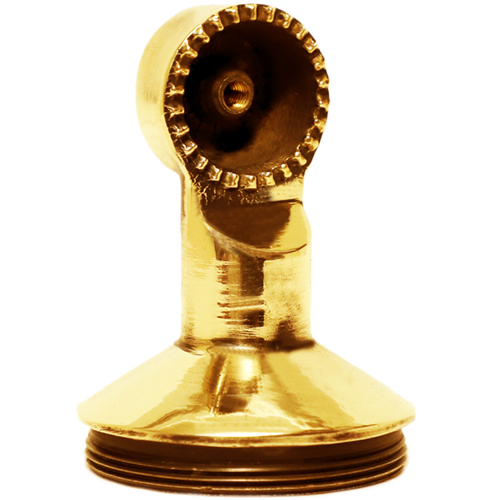

Intricate gold-colored investment casting showing complex internal features

We attach the wax patterns to a central sprue to create a “tree” of parts. This allows us to cast multiple parts at once. The gating system is designed to ensure proper metal flow and minimize defects.

Getting the gating right takes experience. You need to consider things like metal viscosity, cooling rates, and potential porosity issues.

Step 3: Ceramic Shell Creation

Precision cast metal fittings with various sizes and configurations

This is where the magic happens. We dip the wax tree into a ceramic slurry, then coat it with refractory sand. We repeat this process 5-7 times, building up a strong ceramic shell about 6-10mm thick.

The first coat is the most important – it determines the surface finish of the final part. We use very fine particles for this initial layer.

Step 4: Dewaxing

Complex engine block component produced using precision casting technology

We heat the ceramic shell to about 900°C to melt out the wax. The wax flows out through the gating system, leaving a perfect cavity that matches our original pattern.

We collect the wax and reuse it – it’s a very sustainable process with minimal waste.

Step 5: Metal Casting

Molten metal being poured into ceramic molds during the precision casting process

We preheat the ceramic shell to 800-1000°C, then pour molten metal into the cavity. The preheating helps prevent thermal shock and ensures proper metal flow.

Temperature control is crucial here. If the metal is too hot, you get excessive shrinkage. If it’s too cool, you get incomplete filling.

Step 6: Shell Removal and Finishing

Highly polished metal surface showing the smooth finish achievable with precision casting and finishing

Once the metal has solidified and cooled, we break away the ceramic shell using vibration, sandblasting, or water jetting. Then we cut the parts from the sprue and perform any necessary finishing operations.

This is where you really see the quality of the casting. A good precision casting should require minimal finishing work.

Materials for Precision Casting: What You Can Use

One of the great things about precision casting is that you can use almost any metal or alloy. I’ve worked with everything from stainless steel to titanium to superalloys like Inconel. Let me break down the most common materials and their applications.

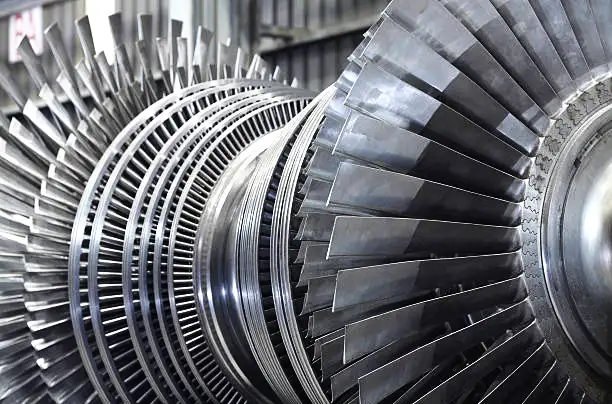

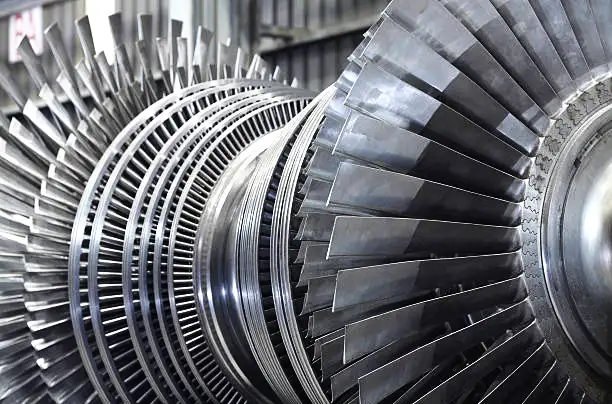

Superalloy turbine blade produced using precision casting for high-temperature applications

Complex turbine engine components showing the precision and detail achievable with investment casting

| Material Type | Common Alloys | Key Properties | Typical Applications |

|---|---|---|---|

| Stainless Steel | 304, 316, 17-4 PH | Excellent corrosion resistance, good strength | Valves, pumps, surgical tools, marine components |

| Carbon Steel | 1018, 1045, 4140 | High strength, good machinability | Mechanical parts, gears, automotive components |

| Superalloys | Inconel, Monel, Hastelloy | Excellent high-temperature properties, corrosion resistance | Aerospace components, turbine blades, chemical processing equipment |

| Titanium | Ti-6Al-4V, Ti CP | High strength-to-weight ratio, biocompatible | Medical implants, aerospace parts, marine components |

| Aluminum | 6061, 7075, A356 | Lightweight, good thermal conductivity | Automotive parts, electronics housings, aerospace components |

| Copper Alloys | Brass, bronze, copper nickel | Excellent electrical conductivity, corrosion resistance | Electrical components, marine hardware, plumbing fixtures |

Material Selection Tips from My Experience

“When choosing a material, I always start with the end application. If it needs to withstand high temperatures, I’ll go with a superalloy like Inconel. If weight is a concern, titanium or aluminum is the way to go. For corrosive environments, stainless steel or Hastelloy works best.”

“I also consider the casting process itself. Some materials flow better than others, which affects the complexity of parts you can create. Titanium, for example, requires special handling due to its high reactivity at high temperatures.”

Surface Finishing: Making Your Parts Look and Perform Their Best

Precision casting already gives you a good surface finish right out of the mold, but sometimes you need something better. Over the years, I’ve developed a lot of expertise in surface finishing techniques for cast parts.

Highly polished precision cast components with mirror-like surface finish

Decorative cast metal component with intricate detailing and polished surface

Common Surface Finishing Processes

Sandblasting

This is the most basic finishing process. We use compressed air to blast fine sand or glass beads at the part surface. It removes any remaining ceramic material and gives a uniform matte finish.

Ra value: 3.2-6.3μm. Great for preparing surfaces for painting or plating.

Tumbling

We put parts in a rotating barrel with abrasive media and compounds. It’s great for deburring and rounding edges on multiple parts at once.

Ra value: 1.6-3.2μm. Perfect for small to medium-sized parts that need consistent finishing.

Polishing

This is where we really make parts shine. We use abrasive wheels and compounds to create a smooth, reflective surface. It can be done manually or with CNC machines.

Ra value: 0.2-0.8μm. Used for decorative parts, medical devices, and components that need to be easy to clean.

Electroplating

We apply a thin layer of metal (chrome, nickel, zinc) to the part surface using electrolysis. It improves corrosion resistance and appearance.

Great for automotive parts, plumbing fixtures, and decorative components.

Anodizing

This is specifically for aluminum parts. We create a protective oxide layer on the surface that’s hard and corrosion-resistant.

Can be done in various colors. Common in aerospace, automotive, and consumer electronics.

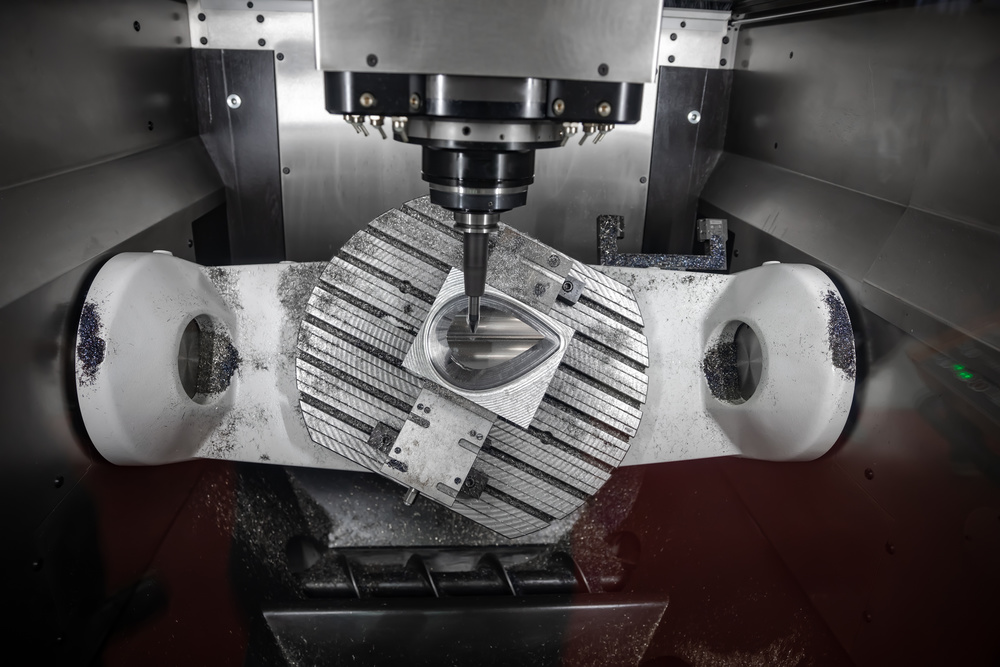

Precision Casting vs CNC Machining vs 3D Printing: Which is Best?

I get asked this question all the time. The truth is, there’s no one-size-fits-all answer. It depends on your specific requirements. Let me compare these three popular manufacturing methods based on my hands-on experience.

Complex precision cast component showing the intricate details that would be difficult or impossible to achieve with CNC machining

| Comparison Factor | Precision Casting | CNC Machining | 3D Printing |

|---|---|---|---|

| Tolerance | ±0.1mm per 25mm | ±0.025mm (standard) | ±0.1mm (FDM) to ±0.025mm (SLA) |

| Surface Finish | Ra 3.2-6.3μm (as-cast) | Ra 0.2-0.8μm | Ra 3.2-12.5μm (as-printed) |

| Design Freedom | Excellent for complex geometries | Limited by tool access | Unlimited design freedom |

| Material Waste | 5-10% | 30-70% | Less than 5% |

| Production Speed | 1-2 weeks (with tooling) | 1-3 days (simple parts) | 1-10 days per part |

| Volume Suitability | 100-10,000+ parts | 1-1,000 parts | 1-100 parts |

Test Data Reference (For Reference Only)

“In a recent comparison test we did for a medical component, we found that precision casting had a mean discrepancy of 120.20μm compared to CNC machining’s 92.15μm and 3D printing’s 111.85μm. While CNC was the most precise, precision casting offered a better balance of precision and design complexity.”

“For mechanical properties, we tested tensile strength on identical parts made with each process. Precision cast parts had 95% of the strength of CNC machined parts, while 3D printed parts had only 75-85% depending on the orientation.”

When to Choose Which Process

- Choose precision casting when: You need complex geometries, moderate to high volumes, and good mechanical properties

- Choose CNC machining when: You need the highest precision, simple to moderate complexity, and small to medium volumes

- Choose 3D printing when: You need rapid prototyping, highly complex geometries, or very small volumes

Where Precision Casting Shines: Industries and Applications

Precision casting is used in almost every industry you can think of. I’ve worked on projects for aerospace, medical, automotive, marine, and many other sectors. Let me share some of the most common applications I’ve seen.

Aerospace Industry

High-precision aerospace turbine components produced using investment casting technology

This is one of the biggest users of precision casting. I’ve made turbine blades, engine components, structural parts, and even satellite components. The ability to create complex shapes with high-temperature materials makes precision casting ideal for aerospace applications.

Medical Industry

Various orthopedic trauma implants produced using precision casting

Precision cast spinal implant showing the intricate detail required for medical applications

Precision casting is perfect for medical devices because it can create complex, biocompatible parts with excellent surface finish. I’ve made surgical instruments, orthopedic implants, dental components, and even parts for MRI machines.

Automotive Industry

Complex automotive engine component produced using precision casting

From engine components to brake systems to decorative trim, precision casting is used throughout the automotive industry. I’ve made everything from intake manifolds to suspension components to custom wheels.

Marine Industry

Precision cast marine fittings with excellent corrosion resistance

The corrosion resistance of materials like stainless steel and bronze makes precision casting ideal for marine applications. I’ve made propellers, valves, pumps, hull fittings, and even parts for submarines.

Oil and Gas Industry

Precision casting can handle the harsh environments of oil and gas exploration and production. I’ve made valves, pumps, connectors, and downhole components that can withstand high pressure and corrosive fluids.

How to Get Custom Precision Cast Parts: My Step-by-Step Process

If you’re thinking about getting custom precision cast parts, let me walk you through the process I use with my clients. This is based on years of experience and helps ensure we get it right the first time.

Custom precision cast component showing the intricate design possibilities

Step 1: Design Consultation

We start by discussing your requirements – what the part does, what environment it will be used in, what tolerances you need, and any special requirements. I’ll give you feedback on design for manufacturability.

Step 2: Material Selection

Based on your requirements, we’ll choose the best material for your application. I’ll explain the pros and cons of different options and help you make an informed decision.

Step 3: Tooling and Pattern Making

We’ll create the necessary tooling or patterns for your parts. For small runs, we might use 3D printing. For larger volumes, we’ll create metal molds for injection molding wax patterns.

Step 4: Sample Production

We’ll produce a small number of samples for you to inspect and test. This is your chance to make sure everything meets your requirements before we go into full production.

Step 5: Production and Quality Control

Once you approve the samples, we’ll go into full production. We’ll inspect every part to ensure it meets our strict quality standards before shipping.

Pros and Cons: What I Love and What Challenges Me About Precision Casting

The Advantages

- Design Freedom: You can create complex geometries that would be impossible or extremely expensive with other methods

- Material Versatility: Almost any metal or alloy can be precision cast

- Good Surface Finish: As-cast parts have a decent surface finish that often requires minimal finishing

- Cost-Effective for Medium to High Volumes: Once tooling is created, per-part costs are relatively low

- Minimal Material Waste: Much more efficient than CNC machining

The Challenges

- Tooling Costs: Initial tooling can be expensive for small production runs

- Lead Time: It takes time to create tooling and patterns

- Size Limitations: Very large parts can be challenging to cast

- Quality Control: Requires careful process control to avoid defects

- Post-Processing: Some parts require additional finishing operations

My Best Tips for Success

“Over the years, I’ve learned a few things that can make your precision casting project go smoother. First, work with an experienced designer who understands the process. Design for manufacturability from the start.”

“Second, don’t skimp on material selection. The right material can make all the difference in performance and durability. Third, invest in good tooling – it will pay off in the long run.”

“Finally, work with a reputable casting supplier who has a proven track record and can provide quality assurance throughout the process.”

Frequently Asked Questions: What My Clients Ask Most

What tolerances can I expect with precision casting?

Typical tolerances are ±0.1mm per 25mm of dimension. For critical features, we can hold tighter tolerances down to ±0.05mm with special techniques. Keep in mind that tolerances can vary depending on the material and part complexity.

How thin can walls be in precision casting?

This depends on the material and part size. For most materials, we can cast walls as thin as 1.5mm for small parts and 3mm for larger parts. Some materials like aluminum can be cast even thinner, while superalloys may require thicker walls.

How long does the precision casting process take?

Tooling and pattern making usually takes 2-4 weeks. Production time depends on the quantity and complexity, but typically ranges from 1-3 weeks. So total lead time is usually 4-8 weeks from design approval to finished parts.

Can precision casting be used for prototype parts?

Yes, but it’s not always the most cost-effective option for small prototype runs. We can use 3D printed patterns instead of metal molds to reduce tooling costs and lead time. For very small quantities (1-10 parts), 3D printing might be a better option.

What is the maximum size for precision cast parts?

We can cast parts up to about 1 meter in length and up to 50kg in weight. Larger parts are possible but require special equipment and may have higher costs and longer lead times.

Final Thoughts: Is Precision Casting Right for You?

After working in this industry for over 15 years, I can honestly say that precision casting is one of the most versatile manufacturing processes available today. It offers a unique combination of design freedom, material versatility, and cost-effectiveness for medium to high production volumes.

If you need complex metal parts with good accuracy and mechanical properties, precision casting is definitely worth considering. It’s not always the best choice – sometimes CNC machining or 3D printing might be better – but for many applications, it’s the perfect solution.

Ready to Start Your Precision Casting Project?

If you have a project that could benefit from precision casting, I’d love to help. With years of experience and a commitment to quality, I can help you get the parts you need when you need them.

Contact me today to discuss your requirements and get a free quote!

This guide is based on my personal experience in the precision casting industry. Every project is unique, so be sure to consult with experienced professionals for your specific application.