Imagine a world where every machine—from the tiny gears in your watch to the colossal engines of a Boeing 787—operates flawlessly, with parts so perfectly crafted that even a hair’s breadth of error could disrupt entire systems. That’s the reality precision machined components bring to life. These engineering marvels are the unsung heroes powering industries like aerospace, medical devices, and automotive, where precision isn’t just a luxury—it’s a necessity. Let’s dive into what they are, how they’re made, and why GoldCattle stands as a leader in delivering them with unmatched expertise.

The Core of Precision Machining: Definition and Fundamentals

A precision machined component is a part manufactured to exact specifications, often with tolerances as tight as ±0.005mm (0.0002 inches) . These components are created by removing material from raw blocks (metal, plastic, or composites) using advanced CNC (Computer Numerical Control) machines. Unlike traditional machining, which relies on manual adjustments, CNC technology uses CAD/CAM software to guide tools with micron-level precision, ensuring consistency and accuracy .

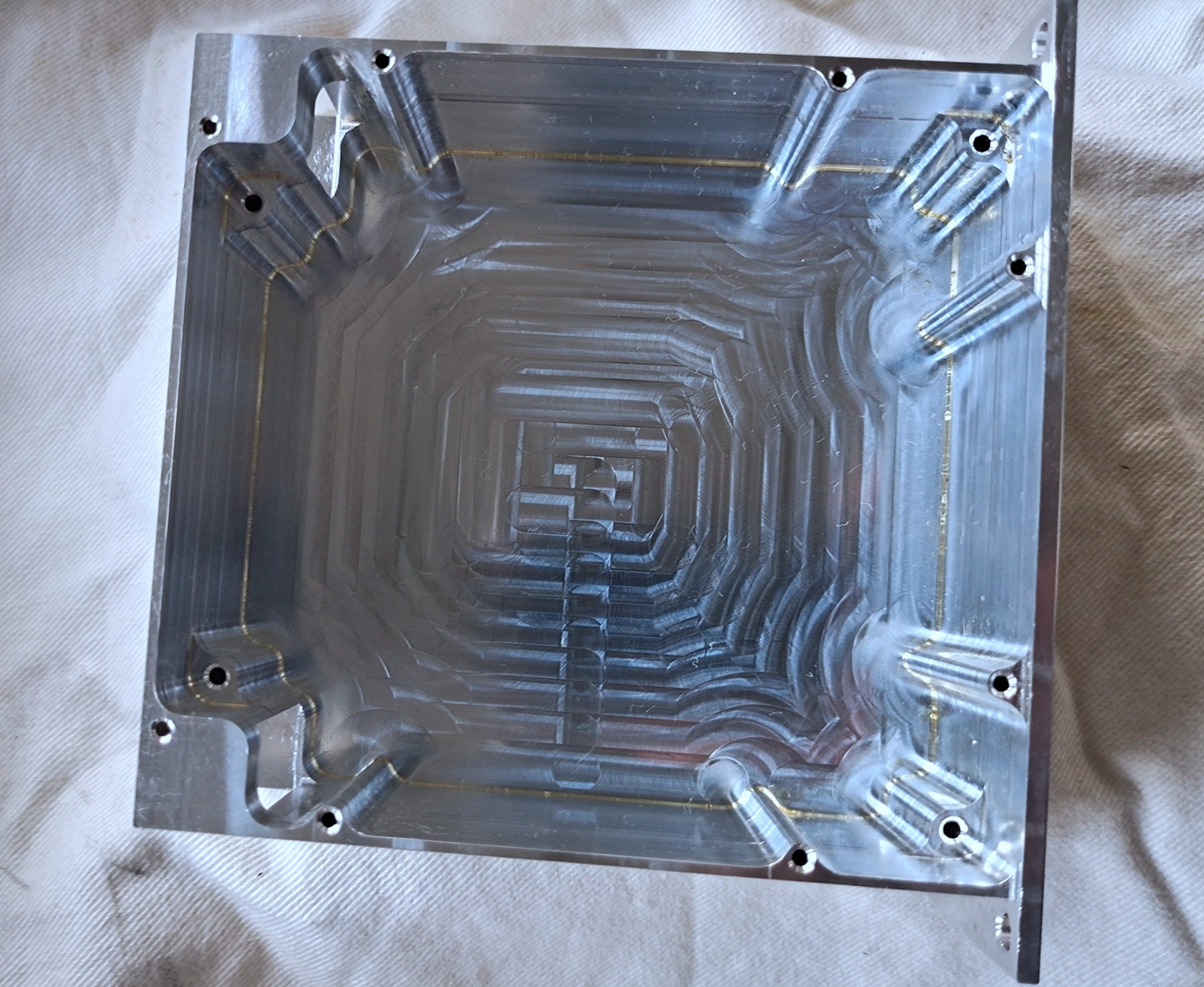

For example, a single aerospace turbine blade might require 5-axis machining to carve its intricate curves, while a medical implant demands surface finishes smoother than a human hair to avoid tissue rejection . The result? Components that fit seamlessly, perform under extreme conditions, and endure rigorous testing—qualities that make them indispensable in high-stakes industries.

The Machinery and Materials: How Precision Components Take Shape

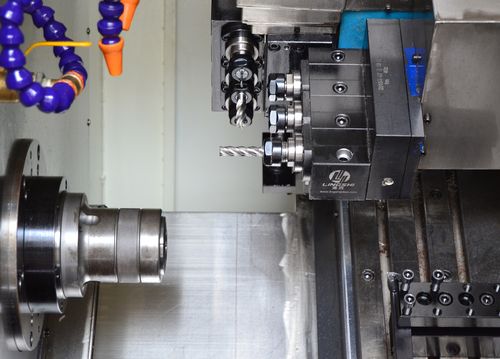

1. Cutting-Edge Equipment

GoldCattle’s state-of-the-art facility includes 5-axis machining centers capable of tolerances down to ±0.005mm . These machines use rotating axes (A and C) alongside linear XYZ axes to sculpt complex geometries in a single setup, eliminating errors from repeated repositioning. For instance, a 5-axis machine can craft a drone propeller’s aerodynamic curves with 40% faster efficiency than traditional 3-axis methods .

2. Material Mastery

The choice of material is as critical as the machining process. Common options include:

- Metals: Aluminum for lightweight strength (e.g., automotive parts), stainless steel for corrosion resistance (medical tools), and titanium for high-stress aerospace applications .

- Plastics: PEEK (Polyether Ether Ketone) is a go-to for medical implants due to its biocompatibility and durability, while nylon excels in high-wear industrial environments .

- Composites: Carbon fiber-reinforced polymers (CFRP) are used in aircraft components to reduce weight without sacrificing structural integrity .

GoldCattle’s 26 years of experience allow them to optimize material selection for each project, balancing cost, performance, and manufacturability.

3. The Process Flow

- Design and Prototyping: Engineers use CAD software to model components, simulating stress points and tolerances.

- CNC Machining: Raw materials are clamped onto machines, where cutting tools (spindles, drills, mills) carve them into shape.

- Quality Control: Components undergo 3D scanning and coordinate measuring machines (CMM) to ensure they meet specs. For example, a medical device might require 100% inspection to guarantee sterility and fit .

- Finishing: Surface treatments like anodizing or plating enhance durability and aesthetics.

This meticulous workflow ensures every part meets ISO 9001 and industry-specific standards, such as AS9100 for aerospace .

Applications Across Industries: Where Precision Components Shine

1. Aerospace and Defense

From jet engine turbines to satellite brackets, precision components here must withstand extreme temperatures, pressures, and vibrations. For instance, a single aircraft engine can contain over 20,000 precision parts, each contributing to fuel efficiency and safety . GoldCattle’s expertise in 5-axis machining makes them a trusted partner for creating lightweight, high-strength aerospace components.

2. Medical Devices

In healthcare, precision isn’t just about functionality—it’s about saving lives. Surgical instruments, MRI components, and orthopedic implants require tolerances as tight as ±0.002mm to ensure compatibility with the human body . GoldCattle’s cleanroom-certified processes and biocompatible material expertise make them a leader in this space.

3. Automotive and Industrial

Electric vehicles (EVs) rely on precision components like battery housings and motor parts to maximize energy efficiency. Meanwhile, industrial machinery demands components that endure heavy loads and harsh environments. For example, a faulty gear in a mining excavator could halt operations costing thousands of dollars per hour . GoldCattle’s custom solutions ensure reliability and longevity.

4. Electronics and Consumer Goods

From smartphone connectors to drone frames, precision components here must balance miniaturization with performance. GoldCattle’s CNC milling and turning capabilities craft intricate parts with micron-level accuracy, ensuring seamless integration into complex systems .

Why Choose GoldCattle for Your Precision Machining Needs?

1. Unmatched Expertise

With 26 years in the industry, GoldCattle has honed its skills in delivering high-precision components across diverse sectors. Their team of engineers collaborates closely with clients to optimize designs for manufacturability, reducing costs and lead times.

2. Advanced Technology

Equipped with 5-axis CNC machines, 3D printing, and automated inspection tools, GoldCattle ensures every part meets the tightest tolerances. Their 5-axis capabilities, for instance, enable complex geometries that traditional methods can’t achieve .

3. End-to-End Solutions

From prototyping to mass production, GoldCattle offers a full suite of services, including mold design, surface finishing, and assembly. This 一站式解决方案 streamlines workflows and ensures consistency from concept to completion.

4. Quality Assurance

Every component undergoes rigorous testing, from CMM inspections to material analysis. GoldCattle’s adherence to ISO standards and customer-specific requirements guarantees defect-free parts, even for high-volume orders .

FAQs About Precision Machined Components

Q: What’s the smallest tolerance GoldCattle can achieve?

A: Our 5-axis CNC machines consistently deliver tolerances as tight as ±0.005mm, suitable for applications like medical implants and aerospace components .

A: Our 5-axis CNC machines consistently deliver tolerances as tight as ±0.005mm, suitable for applications like medical implants and aerospace components .

Q: What materials do you work with?

A: We specialize in metals (aluminum, stainless steel, titanium), engineering plastics (PEEK, nylon), and composites. Our team can recommend the best material for your project’s needs.

A: We specialize in metals (aluminum, stainless steel, titanium), engineering plastics (PEEK, nylon), and composites. Our team can recommend the best material for your project’s needs.

Q: How long does the production process take?

A: Lead times vary by project complexity and volume. For prototypes, we often deliver within 1–2 weeks. High-volume orders are typically completed in 4–8 weeks.

A: Lead times vary by project complexity and volume. For prototypes, we often deliver within 1–2 weeks. High-volume orders are typically completed in 4–8 weeks.

Q: Do you offer design support?

A: Yes! Our engineers provide DFM (Design for Manufacturability) feedback to optimize your designs for cost and efficiency.

A: Yes! Our engineers provide DFM (Design for Manufacturability) feedback to optimize your designs for cost and efficiency.

Q: What industries do you serve?

A: We work across aerospace, medical, automotive, industrial, and consumer goods sectors, tailoring solutions to each industry’s unique demands .

A: We work across aerospace, medical, automotive, industrial, and consumer goods sectors, tailoring solutions to each industry’s unique demands .

Ready to Bring Your Precision Components to Life?

Precision machined components are the backbone of modern innovation, and GoldCattle is your partner in turning ideas into reality. Whether you need a single prototype or thousands of production parts, our team combines cutting-edge technology with decades of experience to deliver excellence.

Reach out today at https://www.xmgoldcattle.com/ to discuss your project. Let’s engineer the future—one perfectly crafted component at a time.

Looking for more insights? Follow us for updates on CNC machining trends, material innovations, and customer success stories!