Cast metal refers to metal alloys formed by pouring molten material into a mold and allowing it to solidify into a specific shape. This manufacturing process has been used for thousands of years and remains essential in modern industry due to its versatility and cost-effectiveness.

As a materials engineer with over 15 years of experience, I’ve worked with cast metals in various industries. From small precision components to large structural parts, cast metal products are all around us. Let’s explore what cast metal is, how it’s made, and why it’s so important.

What Exactly is Cast Metal?

Basic Definition

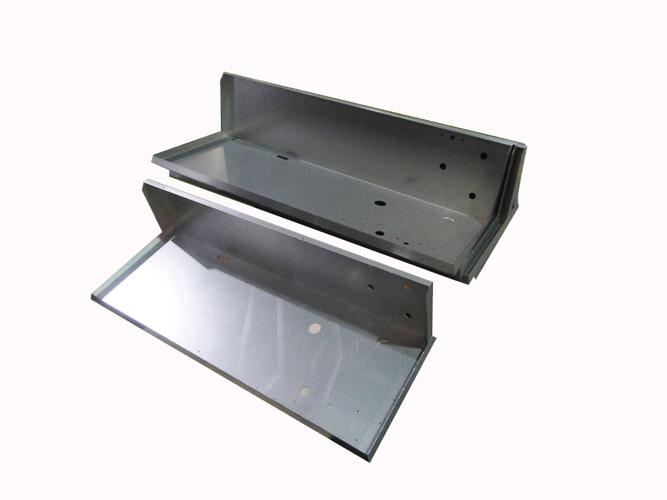

According to industry standards, cast metal is produced through the casting process where:

- Metal is heated to its liquid state

- Molten metal is poured into a mold cavity

- The metal cools and solidifies into the desired shape

- The solidified part is removed from the mold

This differentiates cast metal from wrought metal, which is shaped through mechanical processes like rolling or forging.

Key Characteristics

Cast metal products have unique features:

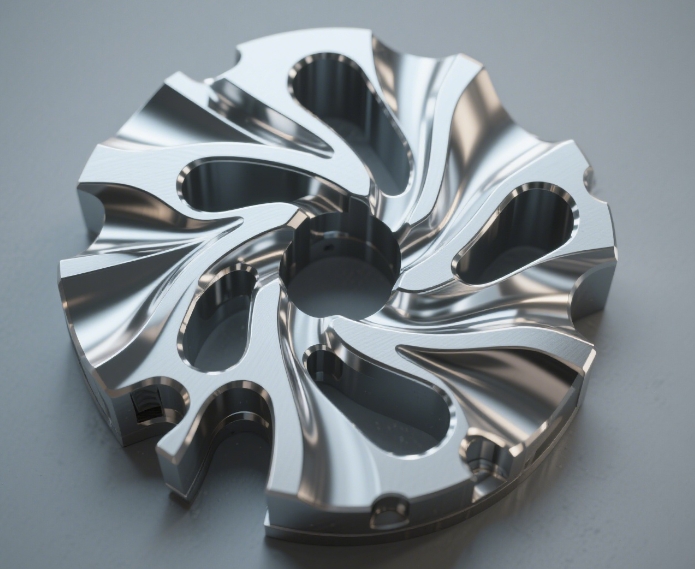

- Complex shapes: Can create intricate geometries not possible with other methods

- Material efficiency: Minimal waste compared to machining from solid blocks

- Cost-effective: Economical for both small and large production runs

- Wide material selection: Works with almost all metal alloys

Common Types of Cast Metals

Ferrous Cast Metals

Cast Iron

Cast iron is one of the most widely used cast metals, containing 2-4% carbon.

Types of cast iron:

- Gray iron: Good vibration damping, used for engine blocks and machine bases

- Ductile iron: Higher strength and toughness, used for pipes and gears

- White iron: Extremely hard and wear-resistant, used for mill liners

Cast Steel

Cast steel has lower carbon content (0.1-1.0%) and offers excellent strength.

Common cast steel types:

- Carbon steel: General purpose, used for valves and pumps

- Alloy steel: Added elements for specific properties like corrosion resistance

- Stainless steel: Contains chromium for excellent corrosion resistance

Non-Ferrous Cast Metals

Aluminum Alloys

Aluminum castings are lightweight (about 1/3 the weight of steel) and corrosion-resistant.

Popular aluminum casting alloys:

- Al-Si alloys: Good casting properties, used for engine components

- Al-Cu alloys: High strength, used in aerospace applications

- Al-Mg alloys: Excellent corrosion resistance, used for marine parts

Copper Alloys

Copper castings have excellent electrical and thermal conductivity.

Main copper casting alloys:

- Bronze (Cu-Sn): High strength and wear resistance, used for bearings

- Brass (Cu-Zn): Good machinability, used for plumbing fittings

- Cupronickel (Cu-Ni): Corrosion resistant, used for marine equipment