How Cast Metal is Made: The Casting Process

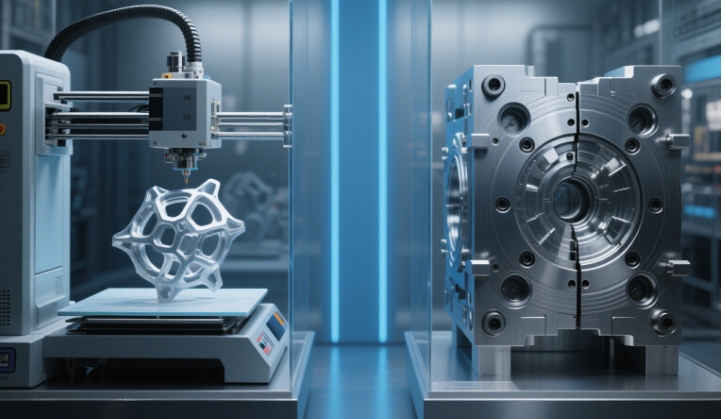

Step 1: Pattern Making

A pattern (positive replica of the part) is created using wood, metal, or plastic. This pattern is used to form the mold cavity.

Step 2: Mold Preparation

The mold is made by packing sand or other refractory material around the pattern. For permanent molds, metal molds are machined to the desired shape.

Step 3: Melting and Pouring

Metal is melted in a furnace at temperatures ranging from 660°C (aluminum) to 1538°C (iron). The molten metal is then poured into the mold cavity.

Step 4: Solidification

The metal cools and solidifies in the mold. The cooling rate affects the final properties of the cast metal.

Step 5: Shakeout and Cleaning

The solidified casting is removed from the mold and cleaned to remove any remaining mold material.

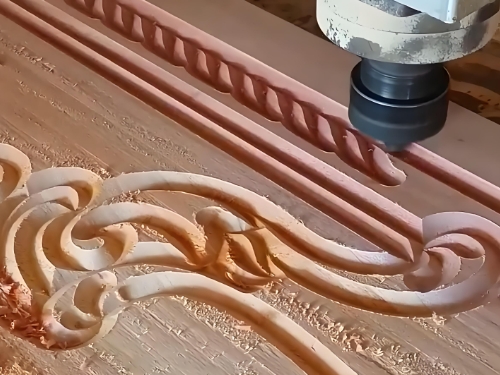

Step 6: Finishing Operations

Additional processes may include:

- Heat treatment: To improve mechanical properties

- Machining: For critical dimensions and surfaces

- Surface treatment: Painting, plating, or coating

Key Properties of Cast Metals

Mechanical Properties

These properties determine how cast metal performs under load:

Strength

- Tensile strength: Resistance to pulling forces

- Yield strength: Stress at which permanent deformation occurs

- Compressive strength: Resistance to crushing forces

Toughness and Ductility

- Impact strength: Ability to absorb energy without breaking

- Elongation: Measure of ductility before fracture

- Hardness: Resistance to indentation and wear

Physical Properties

These properties relate to the material’s physical characteristics:

Density and Weight

- Specific gravity: Ratio of density to water (varies by alloy)

- Mass efficiency: Strength-to-weight ratio is critical for many applications

Thermal Properties

- Melting point: Temperature at which the metal becomes liquid

- Thermal conductivity: Ability to conduct heat

- Thermal expansion: Dimensional change with temperature

Chemical Properties

These properties relate to the material’s chemical behavior:

Corrosion Resistance

- Oxidation resistance: Resistance to reaction with oxygen

- Chemical resistance: Performance in specific environments

- Galvanic compatibility: Behavior when in contact with other metals