Industry Standards for Cast Metals

ASTM Standards

The American Society for Testing and Materials provides important standards:

Ferrous Castings

- ASTM A48: Specification for gray iron castings

- ASTM A536: Specification for ductile iron castings

- ASTM A216: Specification for carbon steel castings

Non-Ferrous Castings

- ASTM B148: Specification for aluminum alloy castings

- ASTM B584: Specification for copper alloy sand castings

- ASTM B804: Specification for magnesium alloy castings

ISO Standards

International Organization for Standardization standards:

- ISO 1083: Cast iron terminology

- ISO 3755: Steel castings for general engineering

- ISO 209: Aluminum and aluminum alloys

Quality Control Standards

- ASTM E18: Standard test methods for Rockwell hardness

- ASTM E8: Standard test methods for tension testing

- ASTM E23: Standard test methods for notched bar impact testing

Practical Applications of Cast Metals

Automotive Industry

Cast metal components are everywhere in cars:

- Engine parts: Cylinder blocks, heads, intake manifolds

- Transmission components: Housings, gears, shift forks

- Chassis parts: Control arms, steering knuckles, brake calipers

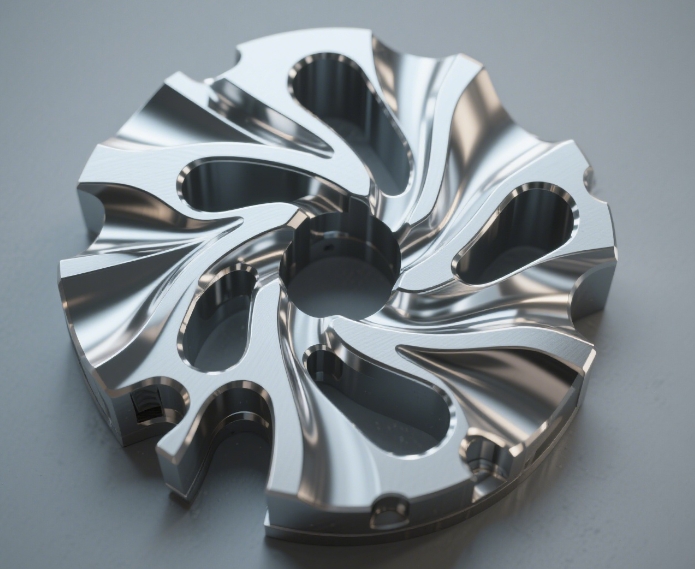

Aerospace Industry

High-performance cast metals are critical:

- Airframe components: Landing gear parts, engine mounts

- Engine components: Turbine blades, combustion chambers

- Structural parts: Wing fittings, fuselage frames

Energy Sector

Cast metals handle demanding conditions:

- Power generation: Turbine casings, generator frames

- Oil and gas: Valve bodies, pump housings, drilling equipment

- Renewable energy: Wind turbine hubs, solar panel supports

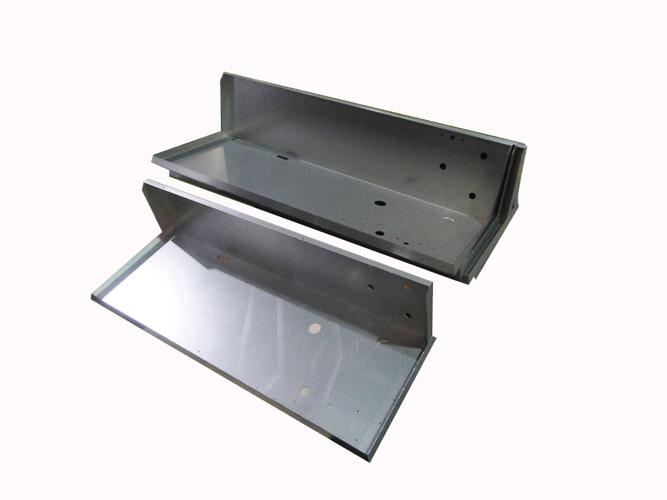

Construction and Infrastructure

Cast metals provide strength and durability:

- Pipe systems: Ductile iron water and sewage pipes

- Structural components: Bridge bearings, architectural elements

- Mechanical systems: HVAC components, fire protection systems

Quality Control for Cast Metals

Non-Destructive Testing (NDT)

These methods check for defects without damaging the part:

Visual Inspection

- Checking for surface defects like cracks, porosity, and misruns

- Using magnifying tools for detailed examination

Radiographic Testing

- Using X-rays or gamma rays to detect internal defects

- Creating images to analyze internal structure

Ultrasonic Testing

- Using high-frequency sound waves to find internal flaws

- Measuring thickness and detecting voids

Magnetic Particle Testing

- Detecting surface and near-surface defects in ferromagnetic materials

- Using magnetic fields and iron particles

Liquid Penetrant Testing

- Revealing surface-breaking defects using colored dyes

- Effective for non-magnetic materials

Mechanical Testing

These tests measure the actual performance:

Tensile Testing

- Pulling the material until it breaks to measure strength

- Determining yield strength, ultimate strength, and elongation

Impact Testing

- Measuring the energy absorbed during fracture

- Evaluating toughness and brittle fracture resistance

Hardness Testing

- Measuring resistance to indentation

- Using Rockwell, Brinell, or Vickers methods

Chemical Analysis

Ensuring the correct composition:

- Spectroscopy: Identifying chemical elements present

- Carbon analysis: Critical for steel and iron castings

- Trace element detection: Checking for impurities