Answer

CNC is the abbreviation of Computer Numerical Control, referring to the technology that enables machine tools (such as milling machines, lathes, machining centers) to automatically complete material cutting and shaping through computer programs. It converts 3D design files into numerical control codes, and drives motors to precisely control the movement trajectory of the cutting tool, achieving high – precision processing of materials such as metals and plastics. It is widely used in industrial manufacturing, prototype development, and mass production.

Explanation

CNC is like an intelligent machine – tool robot that can “read blueprints”. Traditional manual processing is like a chef cooking based on experience, while CNC is like an automatic cooking machine with a pre – set recipe: designers first draw a “dish sample” (3D model) using software, and then convert it into a recipe (numerical control program) that the machine tool can “understand”. The machine tool, like a robotic chef, will accurately pick up materials (such as aluminum blocks), cut, mill, and drill according to the steps, without any manual intervention throughout the process, and finally produce “part dishes” that are exactly the same as the design drawings, and each one has accurate quantity and consistent quality.

Problem Expansion

Core Principles and Composition

The CNC system consists of hardware (machine tool body, servo motors, sensors) and software (CAD design software, CAM programming software). For example, after an engineer designs a part model using SolidWorks, G – code (numerical control instructions) is generated through Mastercam software and transmitted to the machine – tool controller, which drives the XYZ – axis motors to move the cutting tool with micron – level accuracy (±0.01mm) to complete operations such as milling, turning, and drilling. The whole process is like “numbers guiding the knife”, making the machine tool a “thinking robotic arm”.

Technical Advantages

High Precision: The error is controlled within 1/10 of a human hair (0.01mm), far exceeding manual processing, and is suitable for scenarios such as aerospace engine blades and medical precision instruments.

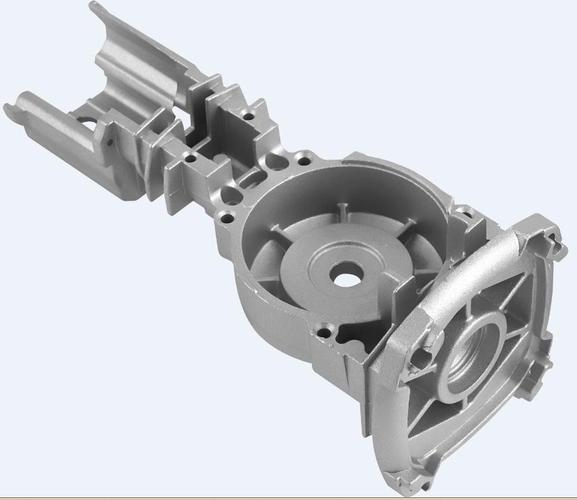

High Efficiency: It can be processed automatically for 24 hours, and complex parts can be formed in one go, 3 – 5 times faster than traditional manual processing. For example, it only takes 4 hours for CNC to process an automotive transmission housing, while it takes 2 days by hand.

Flexibility: Only by modifying the program can the product model be switched without re – adjusting the mechanical structure, which is suitable for small – batch customization (such as 10 – 100 prototypes) and large – scale mass production.

Application Scenarios

Aerospace: Processing titanium – alloy aircraft frames to withstand the pressure at an altitude of tens of thousands of meters;

Automotive Industry: Manufacturing engine blocks to ensure fuel efficiency and emission standards;

Consumer Electronics: Producing aluminum – alloy mobile phone mid – frames, achieving a 0.5mm ultra – thin frame and seamless splicing;

Mold Manufacturing: Engraving the cavity of injection molds, determining the final precision of plastic products.

Differences from Traditional Processing

Traditional machine tools rely on manual operation of the handle, with low precision and depending on the experience of skilled workers (such as old fitters manually grinding parts); while CNC is driven by programs, enabling “novices” to operate the machine tool to produce parts with master – level precision, completely changing the workshop – style production mode of “one person, one machine tool”. It is the cornerstone of intelligent manufacturing in Industry 4.0.

Market Significance

Core Components

- Machine tool body with high rigidity structure

- Servo motors and drive systems (±0.001mm positioning accuracy)

- Precision ball screws and linear guides

- Spindle motor with variable speed control

- Tool changers and automatic workpiece handling systems

- CAD (Computer-Aided Design) software for 3D modeling

- CAM (Computer-Aided Manufacturing) software for toolpath generation

- CNC controller with real-time processing capabilities

- Post-processors for converting CAM data to machine-specific G-code

Types of CNC Machines

Classification by Processing Method

1. CNC Milling Machines

- Axis Configuration: 3-axis, 4-axis, 5-axis configurations available

- Spindle Speed: 8,000-24,000 RPM for high-speed machining

- Positioning Accuracy: ±0.005mm per 300mm travel

- Repeatability: ±0.002mm

- Aerospace components (titanium alloy frames, turbine blades)

- Automotive parts (engine blocks, transmission housings)

- Mold and die manufacturing

- Precision mechanical components

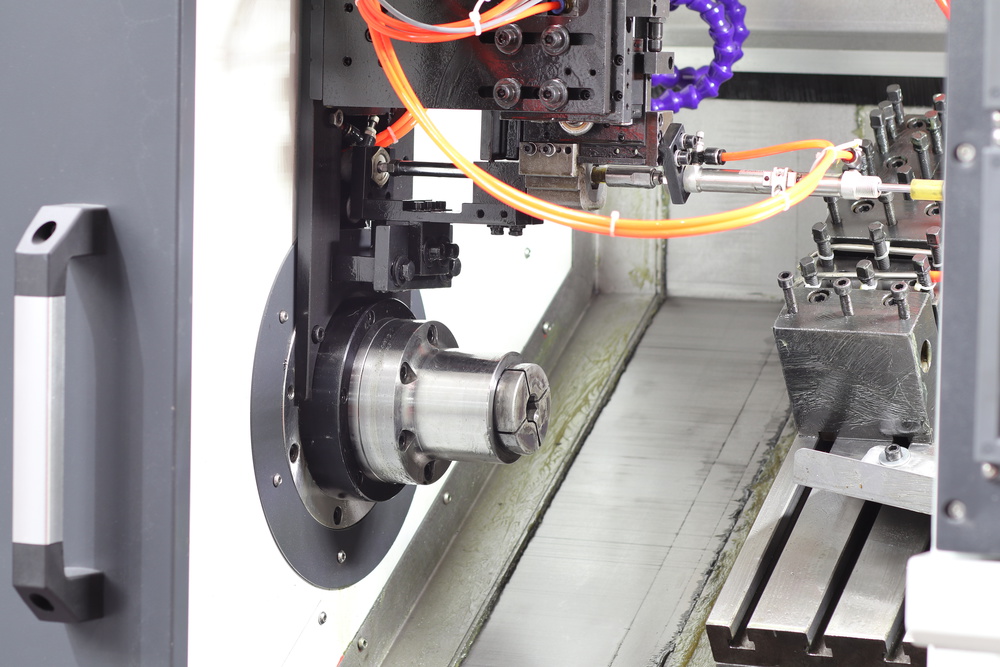

2. CNC Lathes

- Turning Diameter: Up to 1,200mm for large workpieces

- Spindle Power: 5.5-37kW for heavy-duty cutting

- Rapid Traverse: 20-40m/min for efficient positioning

- Tool Stations: 8-12 station turrets for multiple operations

- Shafts, rods, and tubular components

- Threaded parts and precision fasteners

- Hydraulic and pneumatic cylinders

- Medical implants and surgical instruments

3. CNC Routers

- Wood and composite materials

- Plastics and acrylics

- Aluminum and non-ferrous metals

- Foam and insulation materials

- Furniture manufacturing and cabinetry

- Sign making and decorative arts

- Aerospace composite components

- Prototyping and model making

4. 5-Axis CNC Machines

- Simultaneous 5-axis movement for complex geometries

- Tilt and rotate capabilities for undercut machining

- Reduced setup time with multi-sided machining

- Superior surface finish quality

- Aerospace engine components

- Medical prosthetics and implants

- Mold cores and cavities with complex surfaces

- High-precision optical components

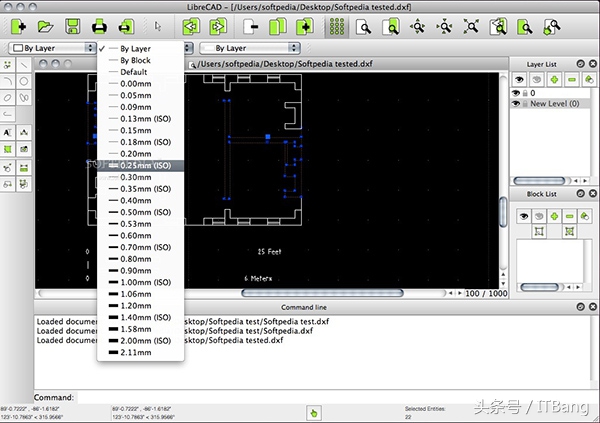

Computer-Aided Design (CAD)

CAD Software Ecosystem

Industry-Standard CAD Tools

General-Purpose CAD

- AutoCAD (Autodesk): Industry standard for 2D drafting and basic 3D modeling

- SolidWorks (Dassault Systèmes): Leading 3D mechanical design platform with parametric capabilities

- CATIA (Dassault Systèmes): Advanced surface modeling for aerospace and automotive industries

Specialized CAD Solutions

- Inventor (Autodesk): Mechanical design with integrated simulation

- Creo (PTC): Parametric and direct modeling capabilities

- Fusion 360 (Autodesk): Cloud-based CAD/CAM platform for collaborative design

Data Exchange Standards

STEP (Standard for the Exchange of Product Model Data)

- AP203/AP214: Most widely used versions for part and assembly data

- Key Features: Supports geometric data, dimensions, tolerances, and material properties

- Industry Adoption: Considered the “gold standard” for aerospace and automotive industries

IGES (Initial Graphics Exchange Specification)

- Legacy Standard: Still supported by many systems but gradually being replaced by STEP

- Limitations: Primarily supports surface geometry with limited PMI (Product Manufacturing Information)

STL (Stereolithography)

- 3D Printing Focus: Simple mesh-based format ideal for additive manufacturing

- Trade-offs: Loses parametric information but offers universal compatibility

CAD Design Process

- Conceptual Design: Creating initial sketches and 3D layouts

- Detailed Modeling: Developing parametric 3D models with precise dimensions

- Assembly Design: Creating multi-component assemblies with proper constraints

- Analysis and Simulation: Performing FEA (Finite Element Analysis) and other simulations

- Documentation: Generating 2D drawings with GD&T (Geometric Dimensioning and Tolerancing)

- Data Preparation: Exporting models in appropriate formats for CAM processing

CNC Machine Operation

Operational Workflow

Pre-Operation Preparation

- Machine Startup: Powering on the CNC system and performing initialization

- Tool Setup: Installing and measuring cutting tools with tool setters

- Workpiece Setup: Mounting and aligning workpieces on the machine table

- Program Loading: Transferring G-code programs to the CNC controller

Production Execution

- Dry Run: Testing the program without cutting to verify toolpaths

- First Article Inspection: Producing and measuring the first part to confirm accuracy

- Production Run: Running the program for batch production

- In-Process Inspection: Periodic quality checks during production

Post-Operation Procedures

- Part Removal and Cleaning: Safely removing completed parts

- Machine Maintenance: Cleaning the work area and performing daily maintenance

- Documentation: Recording production data and quality metrics

- Program Storage: Archiving successful programs for future use

Key Operational Parameters

Cutting Parameters

- Spindle Speed: Rotational speed of the cutting tool (RPM)

- Feed Rate: Linear speed of the tool relative to the workpiece (mm/min)

- Depth of Cut: Amount of material removed per pass (mm)

- Cutting Fluid: Selection and application of coolant/lubricant

Machine Parameters

- Axis Positioning: Real-time monitoring of X, Y, Z coordinates

- Spindle Load: Monitoring motor current to prevent overload

- Tool Wear: Tracking tool life and performance degradation

- Temperature Control: Managing thermal effects on precision

Safety Considerations

- Personal Protective Equipment (PPE): Safety glasses, gloves, hearing protection

- Machine Guards: Proper use of safety enclosures and interlocks

- Lockout/Tagout: Procedures for maintenance and repair

- Emergency Stops: Knowledge of emergency shutdown procedures

CNC vs Manual Machines

Fundamental Differences

Control Method

- Manual Machines: Operated by skilled machinists using handwheels and levers

- CNC Machines: Controlled by pre-programmed instructions executed by computer systems

Precision Capabilities

- Manual Machining: Limited by human skill and physical capabilities (±0.02mm typical)

- CNC Machining: Achieves micron-level precision (±0.001mm possible)

Production Efficiency

- Manual Production: Typically 3-5 times slower than CNC for complex parts

- CNC Production: 24/7 unattended operation with consistent quality

Performance Comparison

|

Performance Metric

|

Manual Machines

|

CNC Machines

|

Improvement Factor

|

|

Positioning Accuracy

|

±0.02mm

|

±0.002mm

|

10x

|

|

Production Speed

|

1 unit

|

3-5 units

|

3-5x

|

|

Labor Requirement

|

1 operator/machine

|

1 operator/3-5 machines

|

3-5x

|

|

Setup Time

|

Hours

|

Minutes

|

5-10x

|

|

Consistency

|

Variable

|

Uniform

|

Significant

|

Cost-Benefit Analysis

Initial Investment

- Manual Machines: (10,000-)50,000

- CNC Machines: (50,000-)500,000+

Operational Costs

- Labor: Reduced by 60-80% with CNC automation

- Material Waste: Reduced by 30-50% through optimized toolpaths

- Quality Costs: Significantly lower scrap and rework rates

Return on Investment

- Typical Payback Period: 12-36 months

- Long-term Savings: 40-60% reduction in production costs

- Competitive Advantage: Ability to produce complex parts profitably

CNC Manufacturing Process

End-to-End Workflow

1. Design and Engineering

- Product Design: Creating 3D models using CAD software

- Manufacturability Analysis: DFM (Design for Manufacturing) considerations

- Process Planning: Determining optimal machining strategies

2. Programming and Setup

- Toolpath Generation: Using CAM software to create machining instructions

- Post-Processing: Converting CAM data to machine-specific G-code

- Machine Setup: Installing tools, fixtures, and workpieces

3. Production and Quality Control

- Machining Execution: Running the CNC program

- In-Process Inspection: Monitoring dimensions during production

- Final Inspection: Verifying conformance to specifications

4. Finishing and Assembly

- Deburring and Surface Treatment: Removing sharp edges and improving surface quality

- Assembly: Combining components into final products

- Packaging and Shipping: Preparing products for delivery

Quality Control Integration

In-Process Monitoring

- Tool Wear Monitoring: Sensors detect tool degradation

- Force Monitoring: Measuring cutting forces to optimize parameters

- Temperature Monitoring: Controlling thermal effects on precision

Post-Process Inspection

- Coordinate Measuring Machines (CMM): 3D measurement of complex geometries

- Vision Systems: Automated optical inspection for surface defects

- Laser Scanning: High-speed 3D scanning for reverse engineering

Industry 4.0 Integration

- IoT Connectivity: Real-time machine monitoring and data collection

- Big Data Analytics: Predictive maintenance and process optimization

- Digital Twin: Virtual simulation of manufacturing processes

- Cloud Collaboration: Remote programming and monitoring capabilities

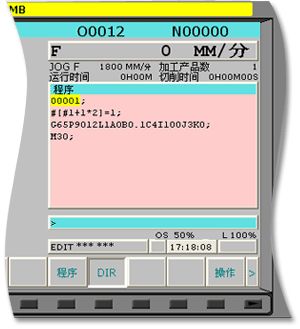

CNC Programming

G-Code Fundamentals

Common G-Codes

- G00: Rapid positioning (maximum machine speed)

- G01: Linear interpolation (controlled feed rate)

- G02: Clockwise circular interpolation

- G03: Counterclockwise circular interpolation

- G04: Dwell (pause for specified time)

- G20/G21: Unit selection (inches/mm)

- G28: Return to machine home position

M-Codes (Miscellaneous Functions)

- M03/M04: Spindle rotation (clockwise/counterclockwise)

- M05: Spindle stop

- M08/M09: Coolant on/off

- M30: Program end and reset

Programming Methods

Manual Programming

- Direct G-Code Entry: Writing code manually for simple parts

- Cycle Time: Hours to days for complex programs

- Skill Requirement: High level of CNC programming expertise

CAM Programming

- Automated Toolpath Generation: Using software to create optimized toolpaths

- Cycle Time: Minutes to hours for complex programs

- Skill Requirement: CAD/CAM software proficiency

Conversational Programming

- Shop Floor Programming: Using machine-specific interfaces

- Cycle Time: Fast for simple to medium complexity parts

- Skill Requirement: Basic CNC knowledge

Advanced Programming Techniques

Subprograms and Macros

- Subprograms: Reusable code modules for common operations

- Macros: Parametric programming for variable geometries

- User Cycles: Customized cycles for specific applications

High-Speed Machining

- Constant Chip Load: Maintaining consistent cutting conditions

- Look-Ahead Function: Previewing upcoming toolpaths

- Smooth Motion Control: Minimizing acceleration/deceleration

CNC Operators and Certification

Role and Responsibilities

- Machine Setup: Installing tools, fixtures, and workpieces

- Program Verification: Testing and optimizing CNC programs

- Production Monitoring: Overseeing the machining process

- Quality Control: Inspecting finished parts

- Maintenance: Performing routine machine maintenance

Required Skills and Knowledge

Technical Skills

- Blueprint Reading: Interpreting engineering drawings and specifications

- Measurement Tools: Using calipers, micrometers, and other precision instruments

- CNC Controls: Operating machine control panels and software

- Troubleshooting: Diagnosing and resolving common issues

Soft Skills

- Attention to Detail: Ensuring precision and quality

- Problem-Solving: Addressing unexpected challenges

- Communication: Collaborating with engineers and programmers

- Continuous Learning: Staying updated with new technologies

NIMS Certification

Certification Levels

- Level I: Basic CNC operation and setup

- Level II: Advanced programming and troubleshooting

- Level III: Mastery of complex machining operations

Certification Requirements

- Written Examination: Testing theoretical knowledge

- Practical Assessment: Demonstrating hands-on skills

- Work Experience: Minimum hours of documented experience

Benefits of Certification

- Industry Recognition: Validates skills to potential employers

- Career Advancement: Opens opportunities for higher-paying positions

- Standardization: Ensures consistent skill levels across the industry

Industry Standards and Certifications

International Standards

ISO Standards

- ISO 6983: Standard for CNC programming language (G-code)

- ISO 286: Geometric product specifications and tolerances

- ISO 9001: Quality management systems

- ISO 14001: Environmental management systems

American National Standards

- ANSI B11: Safety standards for machine tools

- ANSI Y14.5: Dimensioning and tolerancing

- NIST SP 800: Cybersecurity guidelines for industrial systems

Machine Tool Certifications

CE Marking

- Compliance: Meets EU health, safety, and environmental protection standards

- Requirements: Safety guards, electrical safety, noise emissions

SGS Certification

- Quality Assurance: Independent verification of manufacturing processes

- Testing: Performance, safety, and reliability testing

ISO Certifications

- ISO 9001: Quality management systems

- ISO 14001: Environmental management systems

- ISO 45001: Occupational health and safety

Industry Associations

National Institute for Metalworking Skills (NIMS)

- Mission: Developing and maintaining skill standards for metalworking

- Programs: Certification, curriculum development, industry partnerships

American Machine Tool Distributors’ Association (AMTDA)

- Role: Promoting the machine tool industry

- Services: Market research, education, advocacy

Precision Machined Products Association (PMPA)

- Focus: Precision machining industry

- Resources: Technical publications, training programs, networking

Future Trends in CNC Technology

Technological Advancements

Artificial Intelligence Integration

- Adaptive Control: AI algorithms optimize cutting parameters in real-time

- Predictive Maintenance: Machine learning predicts equipment failures

- Autonomous Machining: Self-diagnosing and self-correcting systems

Additive Manufacturing Integration

- Hybrid Machines: Combining CNC subtractive and 3D printing additive processes

- Material Deposition: Building up material in hard-to-reach areas

- Repair and Refurbishment: Restoring worn components

Digital Twin Technology

- Virtual Simulation: Testing programs in virtual environments before physical execution

- Process Optimization: Identifying bottlenecks and inefficiencies

- Remote Monitoring: Overseeing operations from anywhere in the world

Industry 4.0 Implementation

Smart Factories

- Interconnected Systems: Machines, robots, and systems communicating seamlessly

- Data-Driven Decisions: Using real-time data for process optimization

- Flexible Production: Rapid changeover between product variants

Cybersecurity

- Secure Communication: Protecting data transmission between systems

- Access Control: Managing user permissions and authentication

- Threat Detection: Identifying and mitigating cyber threats

Sustainability Initiatives

Energy Efficiency

- Servo Motors: Energy recovery during braking

- LED Lighting: Reduced energy consumption in machine enclosures

- Standby Modes: Lower power consumption during idle periods

Waste Reduction

- Optimized Toolpaths: Minimizing material waste

- Coolant Recycling: Reusing and purifying cutting fluids

- Chip Management: Efficient collection and recycling of metal chips