CNC Machining Mastery

Bro, if you’re looking to level up your CNC game, you’ve come to the right spot! Let’s dive deep into the world of computer numerical control machining like we’re old buddies chatting over a beer.

CNC Machining Processes – The Real Deal

Check out this sick CNC workshop setup – those machines mean business!

Milling – The OG Process

Dude, milling is where it all started! This process uses rotary cutters to remove material from a workpiece. We’re talking 3-axis, 4-axis, and even 5-axis machines that can create some wild geometries.

Turning – For That Perfect Roundness

Turning is when the workpiece rotates while the cutting tool stays stationary. Perfect for making cylindrical parts like shafts, bolts, and those fancy camera lenses. Pro tip: Always use a steady rest for long, thin parts – trust me, I’ve learned the hard way!

EDM – The Cool Kid on the Block

Electrical Discharge Machining is like magic! It uses electrical sparks to erode material. Super useful for super hard metals that regular tools can’t handle. Warning: It’s slow as molasses, but the results are worth it!

Materials – Choose Wisely, My Friend

Metals – The Heavyweights

Aluminum Alloys – My Go-To

Bro, aluminum is the Swiss Army knife of CNC materials! 6061-T6 is my personal favorite – lightweight, corrosion-resistant, and machines like a dream. I’ve used this stuff for everything from drone frames to custom bike parts.

Test Data (for reference only):

- Density: 2.7 g/cm³

- Tensile Strength: 310 MPa

- Machinability Rating: ★★★★☆

Stainless Steel – The Tough Guy

304 stainless is great for kitchen stuff, but 316L is where it’s at for marine applications. Warning: This stuff eats endmills for breakfast! You’ll need slower speeds and lots of coolant. The corrosion resistance is insane though – I’ve seen parts last decades in saltwater.

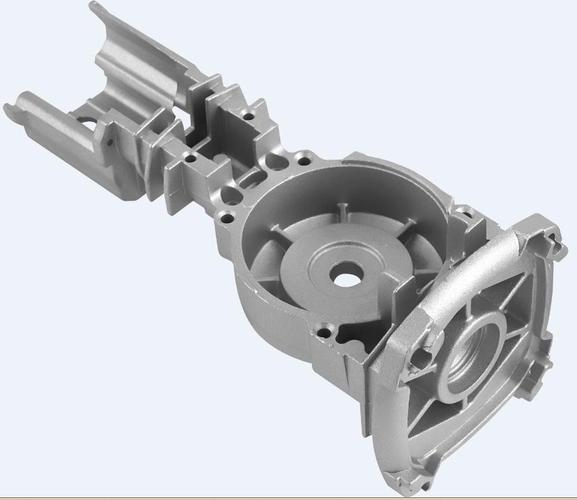

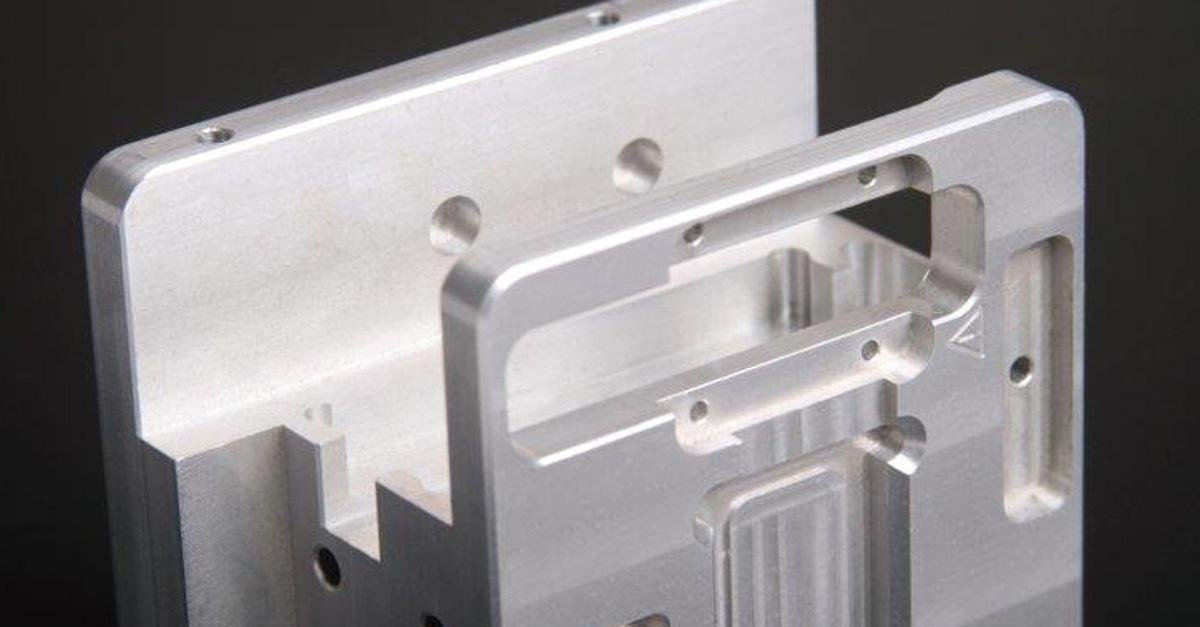

Look at these clean aluminum parts – that’s what proper CNC machining looks like!

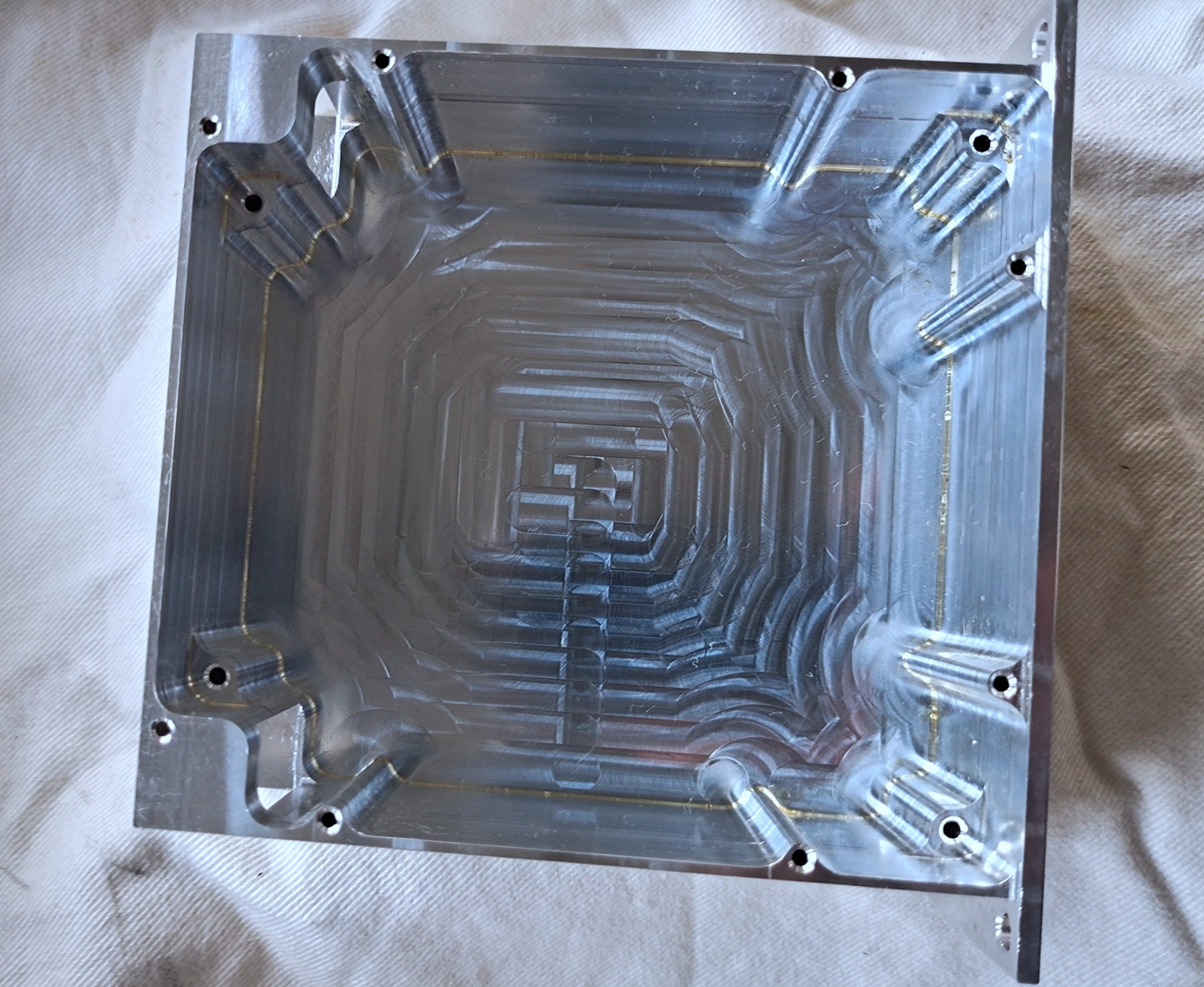

Check out that toolpath pattern – satisfying AF!

Plastics – The Unsung Heroes

Don’t sleep on plastics! ABS is perfect for prototypes – cheap, tough, and easy to machine. PEEK is the Rolls-Royce of plastics though – expensive as hell but can handle high temps and chemicals. I once made a custom part for a chemical plant out of PEEK that’s still going strong 5 years later!

Standards – The Rulebook You Actually Need

Alright, let’s talk standards. I know, boring, but trust me – this stuff will save you from major headaches down the road.

ISO 2768 – The Default

This is your go-to for general tolerances. Most shops will use this unless you specify otherwise. It has three classes:

- f (fine): For precision parts

- m (medium): Your everyday machining

- c (coarse): For rough stuff

ASME Y14.5 – The American Way

If you’re working with US companies, you’ll see this. It’s all about GD&T (Geometric Dimensioning and Tolerancing). More complex but super precise for critical parts.

ISO 13041 – Machine Accuracy

This one’s for testing the machines themselves. It covers everything from positioning accuracy to feed rates. Good to know if you’re buying new equipment!

Tolerances & Test Data – The Nerd Stuff

Disclaimer: All test data below is for reference only – actual results may vary based on machine, tooling, and operator skill!

Pro Tip: Tolerance vs Cost

Here’s a secret most shops won’t tell you: Every 0.01mm tighter tolerance can increase your cost by 15-30%! And if you go below ±0.005mm, you’re looking at 2-3x the price and way longer lead times. Only specify tight tolerances if you absolutely need them!

Real-World Applications – What You Can Make

Aerospace

Turbine blades, engine parts, structural components – this is where CNC really shines. The tolerances here are insane, often ±0.005mm or better.

Medical

Surgical tools, implants, diagnostic equipment – CNC makes parts that can literally save lives. Biocompatible materials are a must here.

Automotive

Engine blocks, transmission parts, custom performance components. I’ve seen guys make entire turbo manifolds on CNC machines!

DIY & Hobbies

Custom guitar parts, RC car components, drone frames – the sky’s the limit! I once made a custom beer tap handle that still gets compliments at parties.

Pro Tips From a Seasoned Machinist

Tooling is Everything

Don’t cheap out on endmills! A good carbide endmill might cost 2-3x more, but it’ll last 10x longer and give better finishes. I once tried to save $5 on an endmill and ended up ruining a $200 aluminum block – not worth it!

Coolant = Your Best Friend

Especially with stainless steel and titanium. Without proper cooling, you’ll burn up tools and get poor surface finishes. I like to use a 10:1 water-to-coolant ratio – works like a charm.

Feed Rates Matter

Too fast and you’ll break tools. Too slow and you’ll waste time. For aluminum, I usually run 1000-1500 mm/min feed rate with 10000 RPM. Stainless steel is more like 300-500 mm/min at 3000 RPM.

Always Do a Dry Run

Before you hit that cycle start button, do a dry run without any material. This saves you from expensive mistakes if your G-code has errors. I can’t tell you how many times this has saved my bacon!

Wrapping It Up

So there you have it, my friend! CNC machining is equal parts art and science. With the right materials, proper tolerances, and a little bit of experience, you can make almost anything your heart desires. Remember, every machinist was once a beginner – don’t be afraid to make mistakes (just try not to make expensive ones!).

Now go out there and make something awesome!