1、Answer

The CNC machining process is a computer-controlled manufacturing method where pre-programmed software dictates tool movements to shape raw materials (e.g., metal, plastic, wood). It involves steps like design (CAD), programming (CAM), material setup, automated cutting/forming, and quality inspection, enabling high-precision production of complex parts.

2、Expansion

Core Stages of the CNC Machining Process

-

Design (CAD Modeling)

- Engineers use software like AutoCAD or SolidWorks to create a 3D model of the part, defining dimensions, tolerances, and surface finishes. For example, designing a turbine blade with intricate airfoil curves or a medical implant with patient-specific geometry.

- Key Output: A CAD file (.step, .stl) that serves as the blueprint for machining.

-

CAM Programming

- CAM (Computer-Aided Manufacturing) software translates the CAD model into G-code (numerical instructions for the CNC machine). This involves:

- Selecting tools (e.g., end mills, drills, lathe tools).

- Defining toolpaths (e.g., roughing to remove most material, then finishing for precision).

- Setting parameters: spindle speed (e.g., 10,000 RPM for aluminum), feed rate (mm/min), and depth of cut (e.g., 0.5 mm for fine details).

- Example: For a CNC mill machining a gear, the CAM software might generate a helical toolpath to cut tooth profiles with 0.02 mm accuracy.

- CAM (Computer-Aided Manufacturing) software translates the CAD model into G-code (numerical instructions for the CNC machine). This involves:

-

Material Setup and Machine Preparation

- The raw material (e.g., a metal billet, plastic block, or wooden plank) is secured in the machine’s workholding device (e.g., a vise, chuck, or vacuum table).

- Calibration: The machine’s axes (X, Y, Z, and rotational axes in 4/5-axis machines) are zeroed to align with the part’s coordinate system. For instance, a CNC lathe must precisely center a steel rod before turning it into a shaft.

-

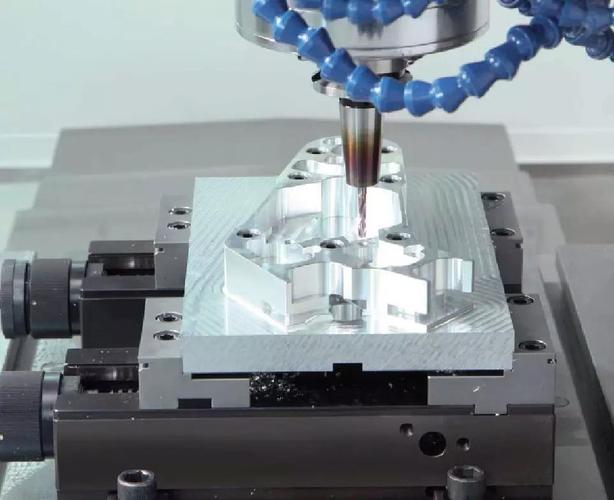

Automated Machining

- The CNC machine executes the G-code, moving tools along precise paths to remove material via cutting, drilling, milling, or turning.

- Multi-Axis Capability: 3-axis machines move along X, Y, Z; 5-axis machines add rotational axes (A, B), allowing simultaneous movement for complex shapes. For example, a 5-axis mill can machine a propeller blade from all angles in one setup, reducing the need for manual repositioning.

- Coolants/Lubricants: Used to reduce heat and tool wear during machining (e.g., cutting oil for steel, air cooling for plastics).

-

Quality Inspection

- After machining, parts are checked against the CAD model using tools like coordinate measuring machines (CMMs) or optical scanners. For example, a aerospace bracket might be scanned to ensure all holes are within ±0.01 mm of design specs.

- Iteration: If errors are found, the G-code is adjusted, and the process repeats until the part meets requirements.

Types of CNC Machines and Applications

- CNC Milling Machines: Use rotating cutters to remove material, ideal for 3D shapes (e.g., engine blocks, aluminum extrusions).

- CNC Lathes: Spin the workpiece while cutting tools shape it (e.g., turning cylindrical parts like shafts, pipes).

- CNC Router: For softer materials (wood, foam, plastic), used in signage, furniture, and prototyping.

- Swiss-Type Lathes: Specialized for small, precise parts (e.g., watch components, medical screws) with high-speed, multi-axis capabilities.

Advantages of the CNC Process

- Precision: Achieves tolerances as tight as ±0.001 mm, critical for industries like aerospace and robotics.

- Efficiency: Runs 24/7 with minimal labor, producing identical parts rapidly (e.g., 1000 smartphone casings per day).

- Complexity: Handles intricate designs impossible by hand, such as lattice structures in 3D-printed molds or turbine blade internal cooling channels.

Challenges: Requires expertise in CAD/CAM and machine operation, with high upfront costs for advanced machines (e.g., a 5-axis mill can cost $500k+). However, its versatility and precision make CNC machining indispensable across manufacturing, from prototyping to mass production.