If you’re a DIY maker testing a prototype, a startup launching a new product, or a manufacturer scaling production, CNC machining service is the backbone of turning your 3D designs into physical parts. But what exactly is it? In short, CNC machining service uses computer-controlled machines to cut, drill, and shape materials (metal, plastic, wood) into precise parts—no manual labor, just consistent, accurate results every time.

Whether you need 10 custom brackets or 1,000 industrial components, the right CNC service can save you time, avoid costly mistakes, and bring your design to life. Below, we break down the key things you need to know: what the service includes, how to pick a good provider, and how to keep costs in check.

1. What Types of CNC Machining Services Are There?

CNC machining isn’t a one-size-fits-all—services are tailored to the complexity of your part and the process needed. Here are the most common types, plus when to use each:

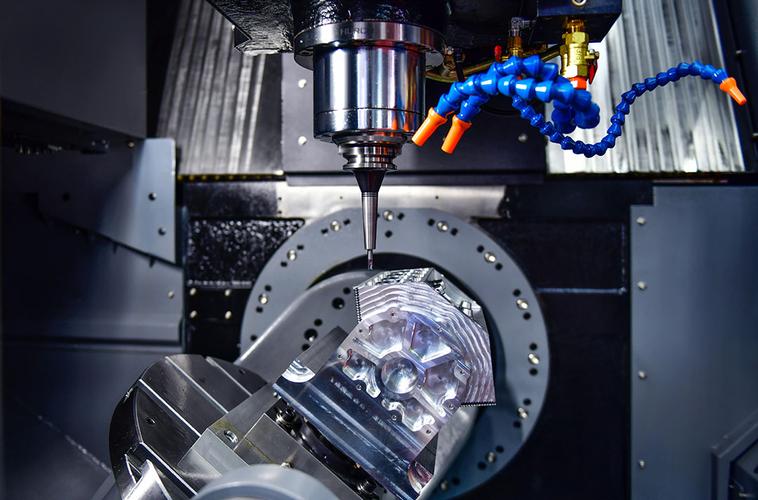

① CNC Milling Service: For Flat/3D Shaped Parts

CNC milling uses rotating cutting tools to remove material from a workpiece, and it’s the most versatile CNC service.

- 3-Axis Milling: The most common (and affordable) option. It cuts along 3 axes (X, Y, Z) and works for simple to moderately complex parts—like flat brackets, electronic enclosure panels, or DIY drone frames. Great for small batches (1–50 parts) and parts with basic holes/slots.

- 5-Axis Milling: For complex, 3D-shaped parts. It adds 2 rotational axes, so the machine can reach every angle of the workpiece—no need to reposition the material. Ideal for intricate parts like aerospace components, medical device casings, or curved automotive parts. It’s pricier than 3-axis but eliminates rework (and mistakes) for complex designs.

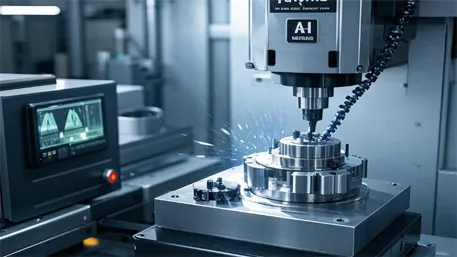

② CNC Turning Service: For Cylindrical Parts

CNC turning spins the workpiece while a cutting tool shapes it—perfect for round or cylindrical parts.

- Manual vs. Automatic Turning: Most services use automatic CNC turning (faster, more consistent) for parts like bolts, nuts, cylindrical sensor casings, or portable speaker shells. It’s faster than milling for round parts—for example, making 100 metal bolts via turning takes half the time of milling.

- Swiss Turning: A specialized type for tiny, precise cylindrical parts (down to 0.5mm diameter)—like watch components, small electrical pins, or micro-medical parts. It holds ultra-tight tolerances (0.001mm) and is a must for miniaturized designs.

③ Custom CNC Prototyping Service: For Testing Designs

Many providers offer dedicated prototyping services—focused on fast turnaround and low cost for small batches (1–10 parts).

- What it includes: Quick design feedback (e.g., “This hole is too small for your screw”), material samples (so you can test aluminum vs. plastic), and minor tweaks (like adjusting a bracket’s grip) without extra fees.

- Ideal for: DIY makers testing a first version of a project, startups validating a product before mass production, or engineers refining a part’s fit.

④ High-Volume CNC Production Service: For Scaling

For batches of 100+ parts, high-volume services optimize for speed and low per-unit cost.

- What it includes: Custom fixtures (to hold parts consistently), automated tool changes, and bulk material sourcing (cheaper than buying small quantities yourself). Providers often add quality checks (like 100% dimensional testing) to avoid defects in large runs.

- Ideal for: Manufacturers scaling up a proven product (e.g., making 500 shelf brackets for a furniture line) or businesses needing regular restocks (e.g., 200 electrical connectors monthly).

2. How to Choose a Reliable CNC Machining Service Provider?

Picking the wrong provider can lead to delayed parts, wrong dimensions, or wasted money. Here are 5 non-negotiable checks to make:

① Check Their Equipment & Capabilities

- Do they have the right machines for your part? For example: If you need a 5-axis part, don’t hire a provider that only has 3-axis mills. Ask to see photos of their equipment (or a tour, if local) and confirm they work with your material (e.g., “Do you machine titanium, or just aluminum?”).

- Bonus: Look for providers with quality testing tools—like Coordinate Measuring Machines (CMMs) for checking dimensions, or leak testers for waterproof parts. This ensures your parts match your design.

② Verify Material Compatibility

Not all CNC services work with every material. Make sure they handle your chosen material:

- Common materials: Aluminum (6061, 7075), steel (1018, 304 stainless), brass (C36000), plastics (ABS, PEEK).

- Specialized materials: If you need titanium (for medical parts) or carbon fiber (for lightweight drone parts), confirm they have experience—these materials need special tools (e.g., carbide cutters for titanium) and expertise to avoid breaking.

③ Ask About Turnaround Time

- Prototyping: A good provider should deliver small batches (1–10 parts) in 3–5 business days. If they say 2 weeks, keep looking—prototyping needs speed.

- High-volume: For 100+ parts, 2–3 weeks is standard, but ask if they offer expedited options (e.g., 1 week for an extra fee) in case of emergencies.

- Red flag: Providers who won’t give a clear delivery date—this means they’re disorganized.

④ Check Reviews & Past Work

- Ask for references: A reliable provider will share contact info for past clients (e.g., “Here’s a startup we made drone parts for—you can ask them about our work”).

- Look for industry experience: If you’re making medical parts, hire a provider that’s done FDA-compliant work before. If you need automotive parts, pick one with automotive clients—they’ll understand your industry’s standards.

- Avoid: Providers with no reviews, vague portfolios, or who can’t show examples of parts similar to yours.

⑤ Understand Their Pricing & Communication

- Get a detailed quote: The quote should break down costs (material + machining + finishing) so you know where your money goes. Avoid vague quotes like “(500 for 10 parts”—ask for specifics (e.g., “)200 material, (250 machining, )50 anodization”).

- Communication: Do they respond to emails within 24 hours? Do they explain technical terms in plain language (e.g., “We recommend 3-axis instead of 5-axis because your part is flat”)? Good communication means fewer mistakes later.

3. What Factors Affect the Cost of CNC Machining Service?

Costs vary widely—from (50 for 10 small aluminum brackets to )5,000 for 100 complex 5-axis parts. Here’s what drives the price:

① Part Complexity

- Simple parts (3-axis, few holes): Cheaper. For example, 10 flat aluminum brackets = ~(50–)100.

- Complex parts (5-axis, tight tolerances): More expensive. For example, 10 5-axis aerospace components = ~(500–)1,000.

Why? Complex parts need more programming time, specialized tools, and longer machining (a 5-axis part can take 2–3x longer to make than a 3-axis part).

② Batch Size

- Small batches (1–10 parts): Higher per-unit cost. For example, 1 aluminum part = (30, 10 parts = )150 (per-unit cost drops from (30 to )15).

- Large batches (100+ parts): Lower per-unit cost. For example, 100 aluminum parts = (800 (per-unit cost = )8).

Why? Setup time (programming the machine, preparing tools) is spread across more parts—setup for 1 part vs. 100 parts is the same, so bulk orders save money.

③ Material Type

- Cheap materials: Aluminum (6061), plastic (ABS) → Lower cost. For example, 10 plastic brackets = ~$30.

- Expensive materials: Titanium, stainless steel (316), carbon fiber → Higher cost. For example, 10 titanium brackets = ~(300. Why? Expensive materials cost more per pound (titanium = ~)30/lb vs. aluminum = ~$2/lb) and need specialized tools (which add to labor costs).

④ Precision & Surface Finish

- Loose tolerances (±0.1mm): Cheaper. For example, a basic shelf bracket with ±0.1mm tolerance = ~$5 per part.

- Tight tolerances (±0.005mm): More expensive. For example, a medical part with ±0.005mm tolerance = ~$50 per part.

- Surface finish: Basic finishes (sandblasting) add (0.50–)2 per part; premium finishes (anodization, powder coating) add (2–)5 per part. Raw (unfinished) parts are cheapest but may need extra work.

4. FAQs: Your CNC Machining Service Questions Answered

Q1: Will a CNC machining service help me fix my design if it’s not machinable?

Yes—most good providers offer “design for manufacturability (DFM)” feedback. For example, if your part has a hole too small for their tools, they’ll suggest resizing it before machining. Many even offer free DFM checks for prototypes—this saves you from wasting money on unmakeable parts.

Q2: Can I order small batches (like 5 parts) or do I need to order 100+?

Nearly all providers accept small batches—especially prototyping-focused services. In fact, many specialize in small runs (1–50 parts) for DIY makers and startups. The only exception is some high-volume factories that focus on 1,000+ parts, but these are easy to spot (they’ll say “bulk only” on their website).

Q3: How do I send my design to the service provider?

You’ll need to share a 3D CAD file (common formats: STEP, IGES, STL). If you don’t have a CAD file, some providers offer design help (for a fee) to turn your sketch into a usable file. Always include notes: “This hole needs to fit a 5mm screw” or “The surface should be matte”—this avoids misinterpretation.

Q4: What if the parts don’t match my design?

Reliable providers offer a “quality guarantee”: If parts are out of tolerance (e.g., a hole is too small), they’ll re-make them for free. To avoid this, ask for a “first article inspection (FAI)”—they’ll send you one part to test before making the rest. This is standard for high-precision or large-batch orders.

Q5: Is CNC machining service better than 3D printing for my project?

It depends on your needs:

- Choose CNC machining if: You need strong materials (metal, durable plastic), tight tolerances (±0.005mm), or smooth finishes. It’s better for functional parts (e.g., brackets, connectors).

- Choose 3D printing if: You need a super complex shape (e.g., a hollow lattice part) or ultra-fast prototypes (1–2 days). It’s cheaper for tiny plastic parts but less strong than CNC.

5. Ready to Get Your CNC Machining Project Started?

Tell us about your project below, and we’ll help you find the right CNC machining service:

- What’s your part (e.g., DIY drone bracket, medical sensor casing, automotive part)?

- Do you need a prototype (1–10 parts) or high-volume production (100+ parts)?

- What material and precision do you need (e.g., 6061 aluminum, ±0.01mm tolerance)?

Our team will connect you with a tailored service recommendation, share a free quote, and even help refine your design for manufacturability—so you get parts that fit, work, and stay on budget.