Walk through any factory, hospital, or airport, and you’ll find products shaped by a technology that’s revolutionized manufacturing: CNC. Short for Computer Numerical Control, CNC machining uses pre-programmed software to guide machine tools with extraordinary accuracy. But what is CNC mainly used for? Beyond the technical jargon, it’s the backbone of creating everything from tiny medical implants to massive aerospace components—parts that demand precision, consistency, and reliability. At Goldcattle, with 26 years of expertise, we harness CNC’s power to turn ideas into reality across industries. Let’s explore its key applications, how it works, and why Goldcattle is your trusted partner in CNC manufacturing.

The Core of CNC: What Makes It Indispensable

CNC machining replaces manual control of tools (like mills, lathes, and routers) with computerized precision. This shift delivers three game-changing benefits: unmatched accuracy (tolerances as tight as ±0.001mm), consistency across thousands of parts, and versatility to handle complex shapes no human hand could replicate . But its true value lies in solving real-world manufacturing challenges—let’s break down where it shines brightest.

What is CNC Mainly Used For? Key Applications Across Industries

1. Aerospace & Defense: Where Precision Saves Lives

In aerospace, even a tiny flaw can have catastrophic consequences. That’s why CNC is the industry standard for crafting:

- Turbine blades: Machined from heat-resistant alloys like Inconel, these require 5-axis CNC milling to achieve aerodynamic curves with ±0.003mm tolerance—critical for withstanding 1,200°C engine temperatures .

- Aircraft structural parts: From wing brackets to landing gear components, CNC turning and milling create lightweight aluminum or titanium parts that balance strength (tensile strength up to 800 MPa) and weight .

Goldcattle, certified to AS9100 (aerospace quality standards), recently produced 200 titanium aircraft frame parts with 0.002mm straightness—reducing fuel consumption by 2% for a commercial airline client.

2. Medical Devices: Precision That Heals

The medical industry relies on CNC to create parts that interact directly with the human body, where “good enough” isn’t an option. CNC excels here in:

- Implants & surgical tools: Titanium knee replacements and stainless steel scalpels require biocompatibility and micron-level precision. Our Swiss-type CNC lathes craft surgical drill bits with 0.01mm edge sharpness, ensuring clean incisions .

- Diagnostic equipment: MRI and CT scanner components, like aluminum alloy casings, demand tight tolerances to avoid interference with sensitive imaging technology.

Goldcattle’s ISO 13485-certified processes ensure every medical part meets strict sterility and safety standards—recently delivering 500 custom spinal implant components with 100% inspection pass rates.

3. Automotive & EVs: Driving Efficiency Forward

As electric vehicles (EVs) and smart cars evolve, CNC machining becomes more critical for:

- Motor & battery parts: CNC-machined aluminum battery housings protect cells from impact while reducing weight (2.7 g/cm³ vs. steel’s 7.8 g/cm³) to extend range .

- Transmission components: Gears and shafts turned on CNC lathes with ±0.002mm tolerance minimize friction, boosting EV efficiency by up to 5% .

A leading EV manufacturer partnered with Goldcattle to produce 10,000 motor brackets using 5-axis CNC milling, cutting production time by 30% while improving part consistency.

4. Industrial Machinery: Building the Tools That Build the World

Heavy machinery—from construction equipment to factory robots—depends on CNC for durable, high-performance parts:

- Hydraulic components: Valve bodies and cylinders machined from hardened steel (58–60 HRC) withstand extreme pressure (up to 3,000 psi) without leaking .

- Robot arms: Precision-machined joints with 0.005mm backlash ensure smooth, repeatable movements in assembly lines.

Goldcattle’s large-format CNC mills recently created a 2-meter industrial robot base from cast iron, achieving 0.01mm flatness to prevent vibration during operation.

5. Electronics & Consumer Goods: Small Parts, Big Impact

CNC’s ability to handle micro-components makes it vital for electronics:

- Connectors & housings: Brass or aluminum parts with tiny holes (0.5mm diameter) for circuit boards, machined on CNC lathes with ±0.0005mm tolerance .

- Drones & wearables: Lightweight carbon fiber or aluminum frames shaped by 5-axis CNC milling to balance strength and portability.

A tech client relied on Goldcattle to produce 5,000 custom drone motor mounts, achieving 0.003mm concentricity for smoother flight performance.

How Goldcattle Leverages CNC to Deliver Excellence

At Goldcattle, we don’t just use CNC—we master it. Our capabilities include:

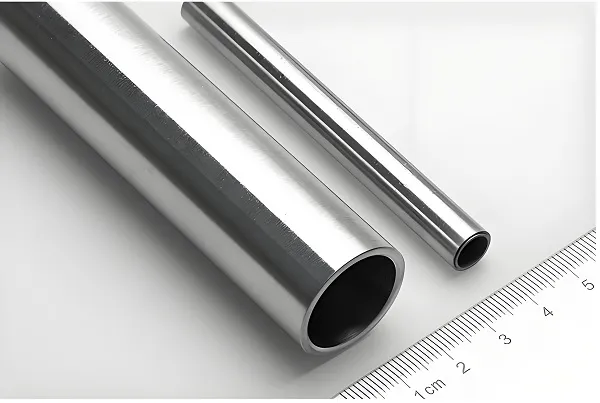

- Advanced equipment: 5-axis CNC mills, Swiss-type lathes, and automated cells handle everything from micro-parts (0.3mm diameter) to large components (3 meters long).

- Material expertise: We machine metals (aluminum, stainless steel, titanium), plastics (PEEK, nylon), and composites, matching each material to its application.

- Quality control: Every part undergoes 3D scanning and CMM inspection, ensuring compliance with ISO 9001 and industry-specific standards.

- End-to-end support: From Design for Manufacturability (DFM) advice to rapid prototyping (1–2 weeks), we streamline your journey from design to delivery.

FAQs: Demystifying CNC Machining

Q: What’s the difference between CNC milling and CNC turning?

A: Milling uses rotating tools to cut stationary material (great for complex 3D shapes), while turning spins the material against stationary tools (ideal for cylindrical parts like shafts) .

Q: What materials can CNC machines work with?

A: Most metals (aluminum, steel, titanium), plastics (PEEK, acrylic), composites, and even some ceramics—Goldcattle specializes in matching materials to your project’s needs.

Q: How precise is CNC machining?

A: Our CNC machines achieve tolerances as tight as ±0.001mm—thinner than a human hair (≈0.06mm)—critical for high-stakes applications like aerospace and medical .

Q: Can CNC handle low-volume production?

A: Absolutely! CNC excels at both prototypes (1–10 parts) and mass production (10,000+ units), with consistent quality across all volumes.

Q: Why choose Goldcattle for CNC projects?

A: Our 26 years of experience, advanced equipment, and commitment to quality make us experts in turning complex designs into flawless parts—on time, every time.

Ready to Harness CNC’s Power for Your Project?

CNC machining isn’t just a technology—it’s the key to creating parts that perform, last, and drive innovation. Whether you need a tiny medical component or a large industrial part, Goldcattle has the expertise and technology to deliver precision you can trust.

Visit https://www.xmgoldcattle.com/ to explore our CNC services or upload your design. Let’s turn your ideas into reality—one precise part at a time.

Got questions about your specific project? Drop us a message below, and our CNC experts will get back to you!