CNC thread machining is a precision manufacturing process that uses computer-controlled machine tools (lathes, mills) to create internal or external threads on workpieces. It employs tools like taps, thread mills, or dies, guided by CNC programs to control feed rates, spindle speeds, and depth, ensuring consistent thread dimensions (pitch, diameter) and accuracy (tolerances like 6g/6H). Used across industries, it replaces manual threading for efficiency and precision.

Detailed Analysis of CNC Thread Machining

1. Core Technologies & Tooling

- Tool Types:

-

- Taps: Used for internal threads, available as hand taps (for manual work) or CNC machine taps (spiral-flute or straight-flute). Spiral-flute taps excel in deep holes (depth >3× diameter) by evacuating chips upward, while straight-flute taps suit shallow holes in brittle materials (e.g., cast iron).

-

- Thread Mills: Rotating cutters with helical teeth create threads via circular interpolation, ideal for large diameters (>20mm) or hard materials (titanium, stainless steel). They offer flexibility—one mill can produce multiple thread sizes by adjusting CNC parameters.

-

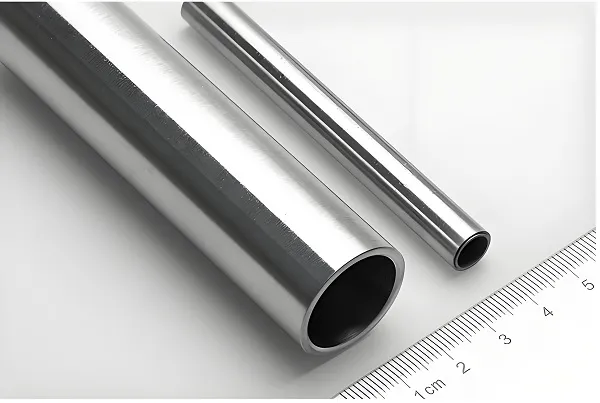

- Dies & Thread Rolling Tools: Dies form external threads on cylindrical workpieces (e.g., bolts), while thread rolling (cold forming) uses dies to displace material, strengthening threads in ductile metals (aluminum, brass) without cutting.

- CNC Programming:

-

- G-codes control threading cycles: G84 (tapping, spindle forward), G74 (left-hand tapping), and G33 (thread milling with linear interpolation). Parameters include pitch (mm or threads per inch), depth, and feed rate (synchronized with spindle speed to avoid thread misalignment).

-

- For thread milling, CAM software generates circular toolpaths with Z-axis increments matching the pitch, ensuring each tooth engages the workpiece at the correct angle.

- Precision Controls:

-

- Thread tolerances (e.g., ISO 6g for external, 6H for internal) require tight spindle-feed synchronization (±0.01mm). CNC systems with closed-loop feedback (linear scales) maintain this synchronization, critical for aerospace threads (tolerance class 4g/4H).

2. Machining Process Workflow

- Pre-Processing:

-

- Material Preparation: Check workpiece material and hardness. Soft metals (aluminum, brass) require sharp tools to avoid tearing, while hard metals (4140 steel) need coated carbide tools (TiAlN) for wear resistance.

-

- Pre-Machining: Drill or bore holes for internal threads (slightly larger than minor diameter: e.g., 8.5mm for M10×1.5 threads). For external threads, turn the workpiece to the major diameter minus 0.1–0.2mm to account for material expansion.

- Thread Machining:

-

- Tapping: The tap is fed into the pre-drilled hole at a feed rate equal to pitch × spindle speed (e.g., 1.5mm pitch at 1,000 RPM = 1,500 mm/min feed). Coolant (oil-based for metals, water-soluble for plastics) flushes chips and lubricates the tap.

-

- Thread Milling: The cutter starts at the thread start position, mills a full circle to create the first thread, then increments axially by the pitch to mill subsequent threads. This method minimizes tool stress, reducing breakage risk in deep holes.

-

- Thread Rolling: Cylindrical workpieces rotate between dies, which press into the surface to form threads. No chips are produced, making it ideal for high-volume parts (e.g., automotive bolts) with improved fatigue strength (30% higher than cut threads).

- Post-Processing & Inspection:

-

- Deburring: Remove burrs from thread roots using brushes or chamfer tools to prevent assembly damage.

-

- Measurement: Thread gauges (ring gauges for external, plug gauges for internal) verify fit. For critical threads, 3D scanners or optical comparators check pitch diameter, flank angle, and lead (axial distance between threads).

3. Material-Specific Considerations

- Metals:

-

- Aluminum/Brass (Soft Metals): Use high-speed steel (HSS) taps at 1,000–2,000 RPM with light cutting fluid to prevent built-up edge (BUE). Thread rolling is preferred for high-volume parts (e.g., brass pipe fittings) to enhance surface finish (Ra <1.6μm).

-

- Steel/Stainless Steel: Carbide taps or thread mills at 500–1,000 RPM with EP (extreme pressure) coolants reduce friction. For 316 stainless steel (corrosion-resistant), use spiral-flute taps to avoid chip clogging in marine applications.

-

- Titanium/Ti-6Al-4V: Low cutting speeds (200–500 RPM) and rigid tool holders prevent tool deflection. Thread milling is safer than tapping here, as titanium’s low thermal conductivity can cause tap overheating and breakage.

- Plastics/Composites:

-

- ABS/PEEK: Use HSS tools with polished flutes to prevent material sticking. Lower speeds (300–800 RPM) avoid melting, critical for medical device threads (e.g., syringe connectors).

-

- CFRP (Carbon Fiber): PCD (polycrystalline diamond) thread mills minimize fiber fraying, ensuring threads in aerospace composite parts (e.g., drone frame fasteners) remain strong and dimensionally stable.

4. Applications Across Industries

- Automotive: Produces bolts, nuts, and engine components (e.g., M12×1.75 threads in crankshafts) using thread rolling for high strength and volume (10,000+ parts/day). Tolerances of 6g/6H ensure reliable assembly.

- Aerospace: Critical threads (e.g., M8×1.25 in turbine casings) require 4g/4H tolerances and NDT (eddy current testing) to detect cracks. Thread milling of titanium alloys ensures consistency in aircraft structural joints.

- Plumbing/Fluid Systems: Pipe threads (NPT, BSP) in brass or stainless steel demand leak-tightness. Tapered threads are machined with precise lead angles (1°47′ for NPT) to seal without gaskets.

- Medical Devices: Threads in surgical tools (e.g., 3mm diameter in bone screws) use biocompatible materials (titanium, PEEK) and smooth finishes (Ra <0.8μm) to avoid tissue irritation. CNC tapping with coolant-through tools prevents contamination.

5. Common Challenges & Solutions

- Thread Misalignment (Cross-Threading): Caused by poor spindle-feed synchronization. Solution: Use rigid tool holders, calibrate CNC axes, and ensure pre-drilled holes are concentric with the spindle.

- Tool Breakage: Occurs in tapping due to chip clogging or excessive speed. Solution: Use spiral-flute taps for deep holes, increase coolant flow, and reduce speed in hard materials.

- Inconsistent Pitch: Stemming from 编程 errors or tool wear. Solution: Verify pitch settings in CAM software, inspect tools for wear, and use in-process probing to adjust offsets.

- Surface Defects (Tearing, Galling): Common in soft metals or unlubricated processes. Solution: Use sharp tools, apply proper coolant, and avoid excessive cutting forces (e.g., reduce feed rate by 10% in aluminum).