Answer

Computer Numerical Control (CNC) is an automated technology that controls machine tool movements and processing via computer program instructions. It uses G-code/M-code to achieve high-precision, repeatable material removal or forming, widely applied in manufacturing automation.

Extended Response

I. Core Definition and Technical Essence of CNC

1. System Composition and Working Principle

- Hardware Architecture:

- CNC system: Controllers like FANUC or Siemens process program instructions and output control signals.

- Servo drives: Convert electrical signals to motor movements, achieving positioning accuracy of ±0.001mm (e.g., Panasonic MINAS servo systems).

- Machine body: Mechanical structures (spindles, guideways) with cooling/lubrication for stable machining.

- Software Logic:

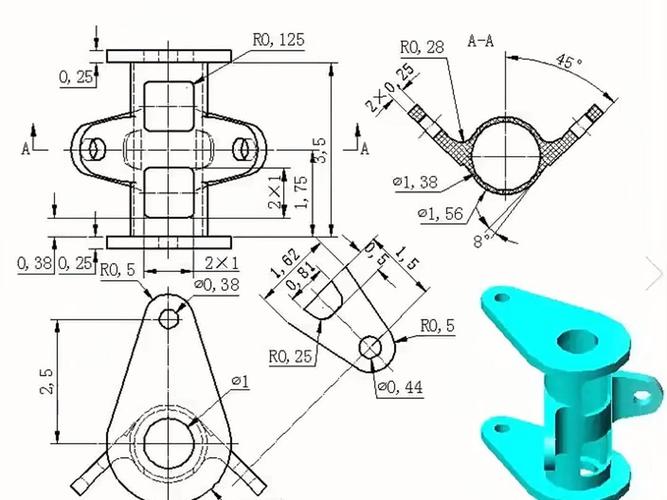

- Generate toolpaths via CAD/CAM software (e.g., UG, Mastercam), post-processed into CNC-readable G-code (e.g., G01 linear interpolation, G02 clockwise arc).

2. Fundamental Differences from Traditional Machine Tools

- Automation level: Traditional tools rely on manual operation; CNC enables full-process program control, reducing human error.

- Precision consistency: Repeat positioning accuracy of ±0.005mm (traditional tools ±0.05mm), ideal for batch production.

- Complex machining capability: 5-axis linkage processes complex surfaces (e.g., turbine blades), unlike traditional multi-step splitting.

II. Key Technical Elements of CNC Systems

1. CNC Programming Language System

- G-code: Controls motion trajectories, e.g.:

- G00: Rapid positioning;

- G03: Counterclockwise arc interpolation.

- M-code: Controls auxiliary functions, e.g.:

- M03: Spindle clockwise rotation;

- M08: Coolant on.

- Macro programs: Use variable programming (e.g., #1=50 for diameter) for batch processing of similar parts.

2. Servo Control Technology

- Position loop: Raster scales (0.1μm resolution) provide real-time feedback for closed-loop control.

- Velocity loop: PID algorithms adjust motor speed to suppress vibration (e.g., stabilizing 3000rpm for aluminum machining).

- Current loop: Servo drives optimize current output for faster motor response (e.g., dynamic torque adjustment during high-speed cutting).

3. Machine Structure Innovations

- Linear motor drives: No lead screw clearance, acceleration up to 10m/s² (e.g., DMG MORI machines).

- Thermal stability design: Marble beds (thermal expansion 1.2×10^-6/℃) + temperature control reduce thermal deformation.

- Vibration damping: Air spring isolation (5-10Hz frequency) for precision work (e.g., optical component milling).

III. Core Application Scenarios of CNC Machining

1. Aerospace Industry

- Typical parts: Titanium alloy engine casings (500mm diameter, ±0.02mm tolerance), carbon fiber composite wing frames.

- Technical challenges: Over 70% difficult materials require 5-axis linkage + minimum quantity lubrication (MQL), cutting speed 80-150m/min.

2. Automotive Manufacturing

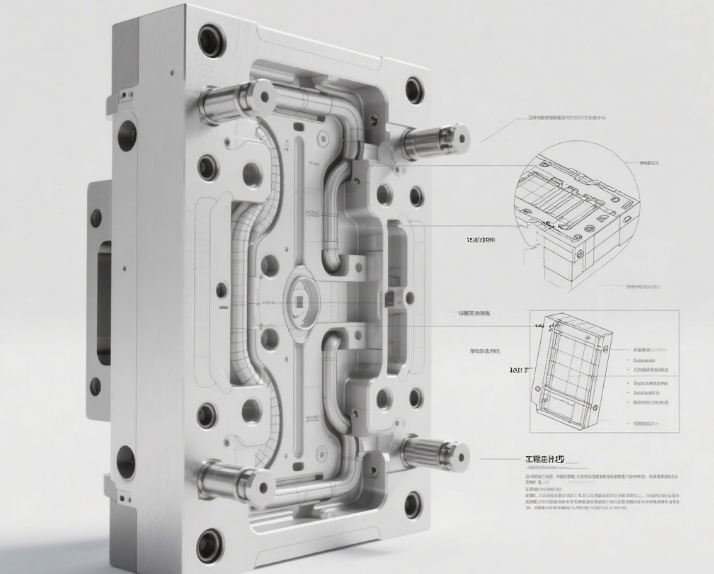

- Mass applications: Engine blocks (HT300 cast iron, H7 hole accuracy), new energy vehicle battery casings (aluminum, 1.5mm wall thickness).

- Efficiency advantages: Flexible production lines with <15-min changeover, 300-parts/24h capacity per machine.

3. Medical Devices

- Precision components: Titanium orthopedic implants (biomimetic texture, Ra≤0.2μm), medical robot joint gears (0.5mm module).

- Special requirements: Compliance with ISO 13485, ISO 8-class cleanroom processing environments.

IV. Process Classification and Characteristics of CNC Machining

| Process Type | Machining Method | Precision Range | Typical Applications |

|---|---|---|---|

| Milling | Rotating tool cutting | ±0.01-0.1mm | Planes, cavities, contours |

| Turning | Workpiece rotation + tool feed | ±0.005-0.05mm | Shafts, disk components |

| Electrical Discharge Machining (EDM) | Pulsed discharge erosion | ±0.002-0.01mm | Micro-holes in hard materials (tungsten steel molds) |

| Laser machining | High-energy laser melting/vaporization | ±0.01-0.1mm | Cutting, drilling, surface treatment |

V. Development History and Trends of CNC Technology

1. Evolution Stages

- 1950s: Vacuum tube CNC systems, 3-axis linkage (e.g., PARSONS’ first CNC mill).

- 1970s: Integrated circuits enable point-to-point/linear control (e.g., FANUC systems).

- 2000s–present: Open CNC systems (e.g., HEIDENHAIN iTNC 640) + intelligent functions (AI parameter optimization).

2. Future Technological Trends

- Industry 4.0 integration: CNC connects with IoT for real-time OEE monitoring (e.g., Siemens Sinumerik Edge).

- Digital twin: Virtual machine simulation predicts tool wear (e.g., Dassault 3DEXPERIENCE).

- Green machining: Dry cutting + energy recovery reduces energy consumption by 30% (e.g., GF Machining Solutions ECOLINE).

VI. Cost and Efficiency Optimization Strategies for CNC Machining

1. Process Planning Optimization

- Toolpaths: Helical ramping replaces vertical plunging to reduce tool impact (20% longer life).

- Cutting parameters: Aluminum high-speed cutting (4000m/min) with 0.2mm/tooth feed balances efficiency and surface quality.

2. Equipment Maintenance Strategies

- Predictive maintenance: Vibration sensors monitor spindle status for early fault warning (e.g., Renishaw Equator).

- Tool management: RFID tags track tool life for automatic replacement alerts (e.g., Sandvik CoroPlus® Tool Manager).

3. Intelligent Production

- Adaptive control: Real-time cutting force monitoring adjusts feed rates (e.g., Makino’s i-SHIFT).

- Cloud collaboration: Industrial internet platforms (e.g., Alibaba supET) optimize multi-plant capacity, boosting equipment utilization by 40%.

VII. Challenges and Solutions in CNC Technology

1. Technical Bottlenecks

- Ultra-precision machining: Nanometer surfaces (Ra≤0.01μm) require specialized machines (e.g., Toshiba NANO-UNITE).

- High-mix low-volume production: Flexible manufacturing cells (FMC) with automatic pallet changers (APC) address rapid changeover needs.

2. Talent Gap

- Solutions: School-enterprise VR training platforms (e.g., FANUC ROBOGUIDE) shorten engineer training to 6 months.

Conclusion

As the core of modern manufacturing, CNC technology has evolved from single-machine automation to intelligence and networking, supporting innovation in aerospace, automotive, and medical fields. With deep integration of AI and digital twin technologies, CNC will become not just a machining tool but a key node in smart manufacturing systems, driving the industry toward efficiency, flexibility, and sustainability.