Metal stamping is a versatile manufacturing process used to shape flat metal sheets into precise, complex parts via dies and presses. It creates components with consistent dimensions, from simple brackets to intricate automotive parts, by cutting, bending, forming, or punching metal. Widely adopted in automotive, electronics, aerospace, and consumer goods industries, it enables high-volume production with cost efficiency and repeatability.

Detailed Analysis of Metal Stamping Applications

1. Core Functions & Technical Capabilities

Metal stamping encompasses a range of operations to transform metal sheets into functional parts, leveraging its ability to handle diverse geometries and volumes:

- Cutting Operations: Blanking (producing flat parts from sheets), piercing (creating holes/slots), and trimming (removing excess material) form the foundation of stamping. These operations use sharp die edges to shear metal cleanly, achieving tolerances of ±0.05mm for simple parts and ±0.02mm for precision components like electrical contacts.

- Forming Operations: Bending (creating angles), drawing (shaping hollow parts), and embossing (adding raised features) reshape metal without removing material. For example, drawing transforms flat aluminum sheets into cylindrical cans, while embossing adds texture to automotive logos for aesthetic appeal.

- Assembly-Ready Features: Stamping can integrate threads, tabs, or interlocking features, reducing post-processing steps. This is critical for high-volume parts like battery contacts, where stamped tabs eliminate the need for welding or fastening.

2. Key Industries & Applications

Metal stamping serves as a backbone for mass production across sectors, delivering parts tailored to specific functional needs:

-

Automotive Industry:

Stamping produces 50–70% of automotive components by volume, including:- Body Parts: Door panels, fenders, and roof skins (mild steel or aluminum) formed via deep drawing and bending, ensuring structural strength and aerodynamics.

- Chassis Components: Brackets, control arms, and brake backing plates (high-strength steel) stamped for durability under load.

- Interior/Exterior Trim: Dashboard brackets, grille inserts, and emblem bases (aluminum or stainless steel) with precise dimensions for seamless assembly.

-

Electronics & Electrical:

Miniature stamping creates small, high-precision parts:- Connectors & Contacts: Copper or brass terminals (0.1–0.5mm thick) with stamped tabs and holes for circuit boards, ensuring reliable electrical conductivity.

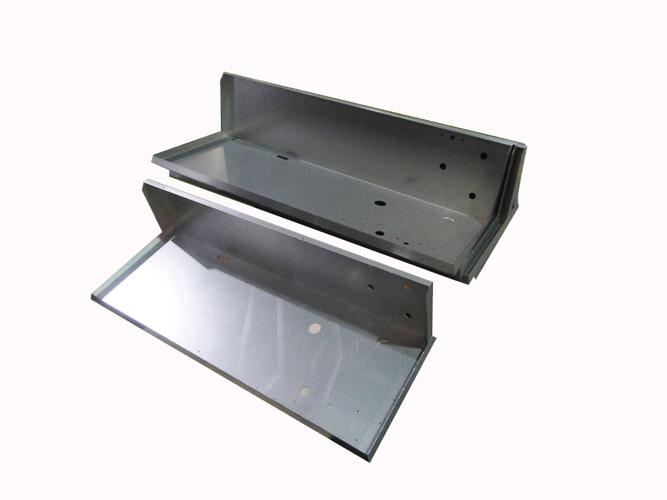

- Enclosures & Shielding: Steel or aluminum casings for smartphones, laptops, and sensors, with EMI/RFI shielding features formed via embossing or folding.

- Battery Components: Nickel-plated steel tabs and casings for lithium-ion batteries, stamped to tight tolerances (±0.01mm) to prevent short circuits.

-

Aerospace & Defense:

Stamping produces lightweight, high-strength parts:- Structural Brackets: Titanium or aluminum alloys stamped for aircraft frames, with precision holes for riveting and minimal weight.

- Fuel System Parts: Stainless steel fuel line clips and brackets, resistant to corrosion and vibration.

- Weapon Components: Trigger guards and magazine parts (carbon steel) stamped for durability and consistent performance.

-

Consumer Goods & Appliances:

Everyday items rely on stamping for cost-effective production:- Appliance Parts: Washing machine drums (stainless steel), refrigerator shelves, and oven door hinges, formed via bending and drawing.

- Hardware: Nuts, bolts, and washers (steel) produced in bulk via progressive stamping, ensuring uniform dimensions for reliable fastening.

- Cookware: Aluminum or stainless steel pans and lids, deep-drawn to achieve uniform thickness and smooth surfaces.

3. Materials Suited for Metal Stamping

Stamping works with diverse metals, chosen for their formability, strength, and cost:

-

Steel Alloys:

- Mild Steel (1018): Easy to stamp, low cost, used for automotive body parts and brackets.

- High-Strength Low-Alloy (HSLA) Steel: Offers better strength-to-weight ratio, ideal for chassis components and structural parts.

- Stainless Steel (304, 316): Corrosion-resistant, used for kitchen appliances, medical equipment, and marine parts.

-

Non-Ferrous Metals:

- Aluminum (3003, 5052): Lightweight and formable, used for automotive panels, electronics enclosures, and beverage cans.

- Copper & Brass: Excellent conductivity, stamped into electrical contacts, connectors, and plumbing fittings.

- Titanium (Ti-6Al-4V): High strength-to-weight ratio, used in aerospace parts despite higher cost and stamping complexity.

-

Material Thickness: Most stamping processes handle 0.05–6mm thick sheets, with progressive dies accommodating thinner materials (0.05–1mm) for electronics, and transfer dies handling thicker metals (1–6mm) for structural parts.

4. Stamping Processes & Equipment

Different stamping methods cater to part complexity and production volume:

- Progressive Stamping: A coil of metal is fed through a series of dies, each performing one operation (piercing, bending, blanking) sequentially. Ideal for high-volume, small parts (e.g., washers, connectors) with production rates up to 1,000 parts per minute.

- Transfer Stamping: Parts are moved between separate dies by robotic arms, suited for larger, complex parts (e.g., automotive fenders) requiring multiple forming steps. Offers flexibility for varying geometries.

- Fine Blanking: Uses specialized dies with a V-ring to compress material during cutting, producing parts with smooth edges and tight tolerances (±0.01mm). Used for precision components like gear teeth or bearing races.

- Hot Stamping: Metals are heated to 800–900°C before stamping, increasing formability for high-strength steels. Creates automotive crash components with enhanced impact resistance.

Equipment ranges from mechanical presses (for high-speed production) to hydraulic presses (for slower, high-force operations on thick materials), with tonnages from 10 tons (small electronics) to 3,000 tons (automotive body panels).

5. Advantages Driving Adoption

Metal stamping’s popularity stems from its ability to balance quality, efficiency, and cost:

- High Volume, Low Cost: Tooling costs are amortized over large production runs, making per-part costs lower than CNC machining for 10,000+ units.

- Consistency & Precision: Dies ensure identical parts with minimal variation, critical for assembly-line compatibility (e.g., automotive parts fitting together seamlessly).

- Material Efficiency: Minimal waste compared to machining, as stamping shapes metal rather than removing large volumes, reducing material costs.

- Speed: Progressive stamping lines produce hundreds to thousands of parts per minute, meeting high-demand industries like automotive and electronics.

From automotive bodies to smartphone components, metal stamping enables the mass production of durable, precise parts across industries, combining technical versatility with economic efficiency to meet diverse manufacturing needs.