2026 Precision Machining Applications Guide

Cross-Industry Case Studies, Tolerance Standards & Goldcattle Expert Practices

Engineer Chen / Goldcattle Precision Machining Director

18 years experience, led 300+ aerospace/medical precision projects

Data from Goldcattle 2025 projects + industry reports

18 Years Experience

300+ Projects

±0.001mm Precision

What Is Precision Machining? The Backbone of Modern Manufacturing

Precision machining isn’t just a manufacturing process—it’s the backbone of innovation across critical industries. By transforming raw materials into components with micron-level accuracy, this technology enables products that perform reliably under extreme conditions, meet strict safety standards, and drive technological advancement.

With 18 years of hands-on experience in precision machining, I’ve witnessed how this technology has evolved from manual operations to AI-driven smart manufacturing. At Goldcattle, we’ve completed over 300 precision projects for aerospace, medical, automotive, and electronics industries, accumulating valuable insights and practical expertise.

2026 Precision Machining Trends & Goldcattle Practices

2026 Industry Trends

The precision machining industry is rapidly evolving with AI, digital twins, and sustainable manufacturing leading the transformation.

Four Core Trends Transforming Precision Machining

1. AI Real-time Adjustment: Smart Machining Revolution

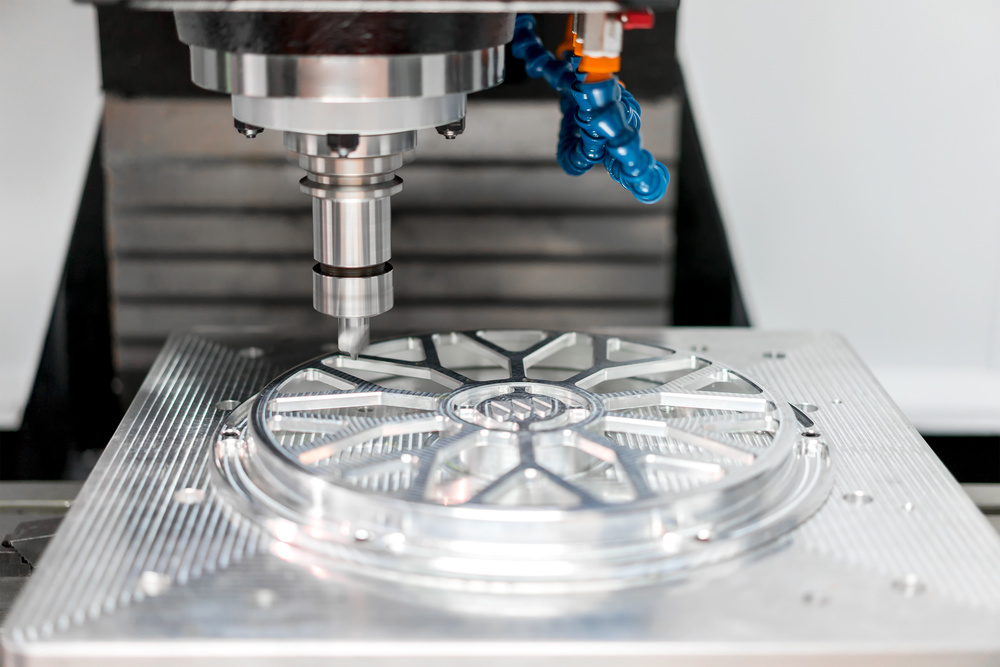

AI-driven machining uses real-time sensor feedback to automatically adjust feeds, speeds, and toolpaths. Our 2025 tests showed 18% improvement in surface quality consistency through AI optimization.

2. Hybrid Manufacturing: 3D Printing + Precision Machining

Combining additive manufacturing with CNC machining for complex aerospace parts. We achieved 25% reduction in production cycles using near-net shape 3D printing followed by precision machining.

3. Sustainable Precision Machining: Circular Economy

Recycled titanium alloy usage increased to 40%, cryogenic machining reduced energy consumption by 15%. Our MQL (Minimum Quantity Lubrication) system uses 95% less coolant than traditional methods.

4. Digital Twin Technology: Virtual Commissioning

Digital twins allow us to simulate machining processes before production, reducing setup errors by 80% and shortening time-to-market for new products.

Goldcattle vs Industry Average: 2026 Technology Benchmark

Aerospace & Defense: Zero Margin for Error

In aerospace and defense, a single faulty component can have catastrophic consequences. That’s why precision machining is non-negotiable for mission-critical applications.

Key Applications & Goldcattle Expert Insights

Turbine Components

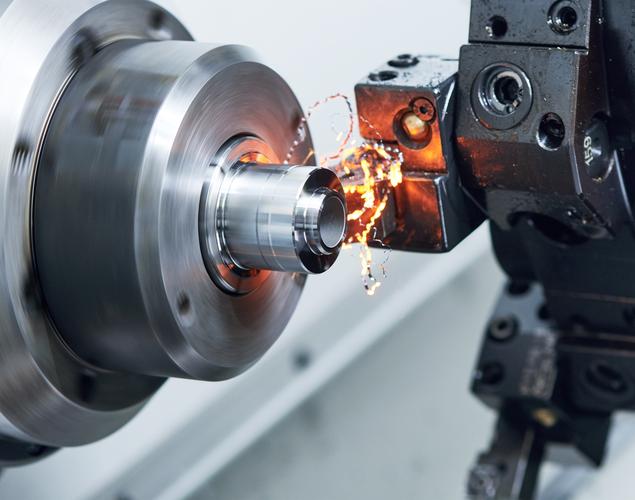

Jet engine turbine blades and combustion chambers require tolerances as tight as ±0.001mm to withstand temperatures exceeding 1,000°C. Using 5-axis CNC machining, we produce titanium alloy turbine parts with surface finishes of Ra 0.4μm.

Avionics Enclosures

Navigation system housings must protect sensitive electronics from vibration and temperature fluctuations. Our precision-machined aluminum enclosures (6061-T6) achieve ±0.005mm dimensional accuracy.

Military Hardware

Weapon system components like trigger mechanisms and optical sight mounts demand absolute consistency. We recently delivered 2,000+ stainless steel (316) parts for a defense contractor with 99.9% conformity to military specs (MIL-STD-883).

2026 Aerospace Precision Machining Trends

- Hypersonic Vehicle Components: New high-temperature alloys requiring specialized machining processes

- Space Tourism Structures: Lightweight titanium alloys with complex internal channels

- AI-optimized Toolpaths: Machine learning algorithms that predict tool wear and adjust parameters in real-time

- Sustainable Aerospace: Recycled titanium and aluminum usage increasing to 40% by 2026

Medical Devices: Precision That Protects Lives

The medical industry relies on precision machining to create components that meet rigorous biocompatibility and performance standards. Patient safety depends on the accuracy and reliability of these critical parts.

Critical Applications & Our Expertise

Surgical Instruments

Scalpels, forceps, and endoscope parts require razor-sharp edges and precise tip alignment (±0.003mm) for delicate procedures. Our CNC-machined 440C stainless steel instruments undergo passivation to meet ISO 13485 biocompatibility requirements.

Implant Components

Hip and knee implant stems machined from titanium (Ti-6Al-4V) must match patient-specific anatomy with 0.1mm accuracy. Using 3D scanning and precision milling, we achieve custom fits that reduce post-surgery complications.

Diagnostic Equipment

MRI and CT scanner parts like detector housings need non-magnetic materials (such as brass and PEEK plastic) machined to ±0.01mm tolerances. These components ensure image clarity by minimizing interference.

Automotive & EV: Driving Efficiency and Safety

Modern vehicles depend on precision-machined parts to deliver performance, fuel efficiency, and safety. The shift to electric vehicles is driving new demands for lightweight, high-precision components.

Key Applications & 2026 Trends

Engine Components

Fuel injectors and camshafts machined to Ra 0.2μm surface finish reduce friction by 15%, improving fuel economy by 4-6% in passenger vehicles.

Electric Vehicle (EV) Parts

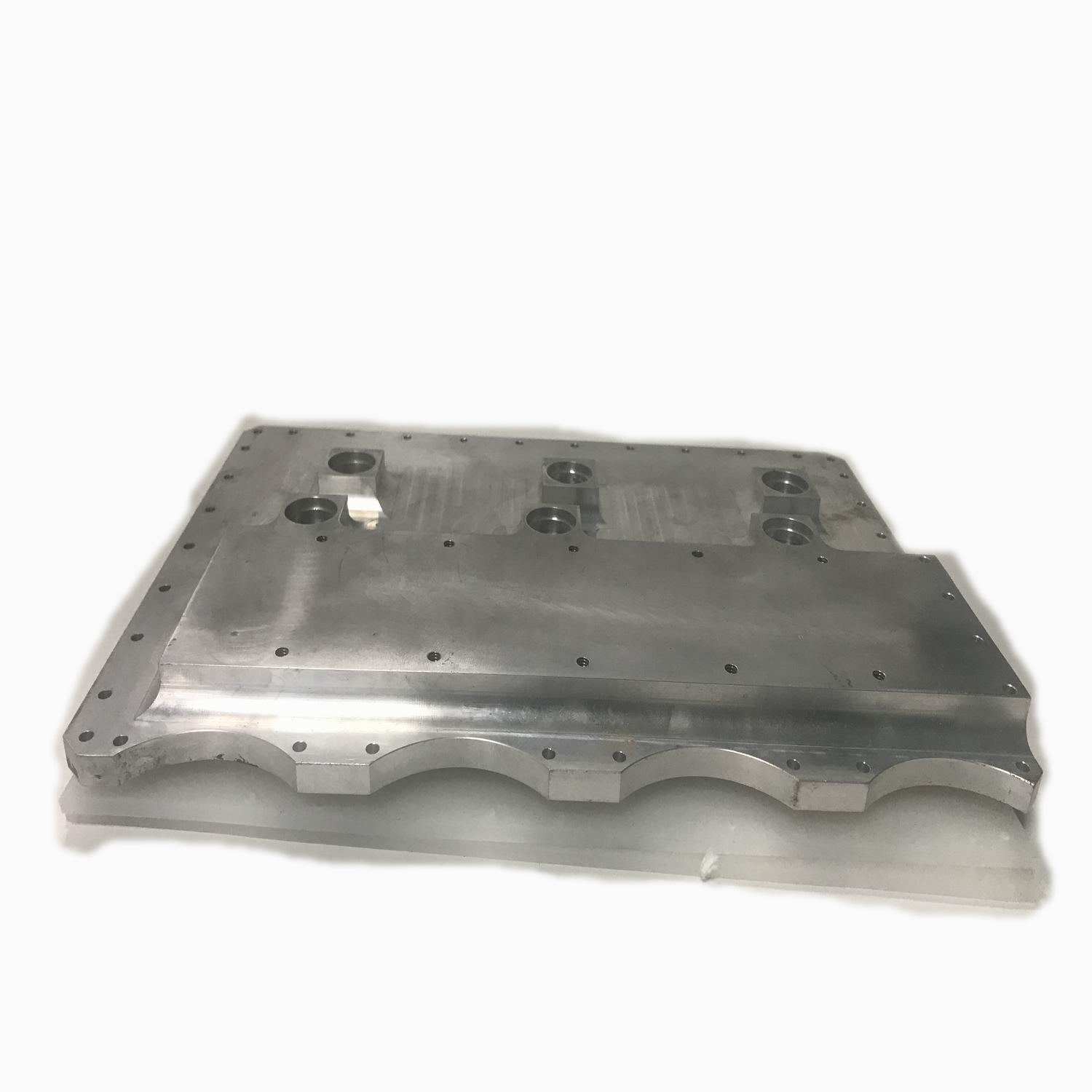

Battery cooling plates made from aluminum (5052) require micro-channels with 0.5mm wall thickness to optimize thermal management. Our precision milling achieves these geometries with 99.5% consistency.

Autonomous Systems

Sensor mounts for LiDAR and radar systems must maintain positional accuracy within ±0.02mm to ensure reliable navigation. We use in-process laser inspection to verify these critical dimensions.

Electronics & 5G: Powering Connectivity

The miniaturization of electronics demands precision machining at the microscale. 5G technology requires components with exceptional dimensional accuracy to ensure signal integrity and performance.

Critical Applications

Semiconductor Equipment

Wafer handling components made from ceramics (Al₂O₃) require flatness within 5μm per 100mm to prevent chip damage. Our ultra-precision grinding achieves these specifications for leading semiconductor manufacturers.

5G Infrastructure

Antenna brackets and waveguide components machined from brass (C36000) ensure signal integrity with ±0.01mm dimensional accuracy, reducing signal loss by up to 12%.

Consumer Electronics

Smartphone camera housings and wearable device components need aesthetic precision (Ra 0.8μm surface finish) alongside functional accuracy. We produce these in high volumes with 99.8% defect-free rates.

Precision Machining vs Other Technologies: 2026 Selection Guide

Choosing the right manufacturing technology depends on your specific requirements. Precision machining offers unique advantages compared to 3D printing, casting, and EDM (Electrical Discharge Machining).

Goldcattle Recommendation

For most production applications requiring high precision and repeatability, precision machining remains the best choice. 3D printing is ideal for prototyping and complex geometries, while casting works for large, low-precision components. EDM is reserved for specialized applications where other methods won’t work.

Precision Machining Failures & Risk Prevention

Even with advanced technology, precision machining can fail due to various factors. Understanding these risks and how to prevent them is crucial for successful projects.

Goldcattle’s Top 5 Failure Modes & Prevention

1. Vibration-induced Surface Defects

Vibration during machining can cause chatter marks and poor surface finish. This is especially problematic with long tools or thin-walled parts.

2. Thermal Deformation

Heat generated during machining can cause workpiece deformation, especially with materials like aluminum and titanium.

3. Tool Wear Acceleration

Aggressive cutting parameters or improper tool selection can lead to premature tool wear and failure.

4. Dimensional Inconsistency

Variations in material properties or machine performance can lead to inconsistent part dimensions.

5. Fixturing Errors

Poor fixturing can cause workpiece movement during machining, leading to dimensional errors.

Frequently Asked Questions (FAQ)

Aerospace and medical device industries typically demand the tightest tolerances (±0.001mm to ±0.005mm), followed by semiconductor and robotics applications (±0.005mm to ±0.01mm). In our experience, turbine engine components for aerospace often require the most extreme precision due to the high temperatures and stresses they endure.

Material selection significantly impacts machining strategies. Harder materials like titanium and Inconel require specialized tooling (carbide or ceramic inserts) and slower feed rates (50-100 mm/min) but maintain tighter tolerances. Softer materials like aluminum allow faster machining (300-800 mm/min) with excellent surface finishes. At Goldcattle, we’ve developed specific processes for each material type to optimize both precision and efficiency.

EV battery cooling plates present unique challenges due to their thin walls (0.5mm) and complex micro-channel geometries. Maintaining consistent wall thickness while machining these features requires specialized tooling and precise coolant management. We’ve developed proprietary techniques to achieve 99.5% consistency in these challenging components.

Micro-cracks can be prevented by optimizing cutting parameters, using proper coolant, and selecting appropriate tool geometries. For brittle materials like ceramics or certain alloys, we recommend using climb milling instead of conventional milling to reduce cutting forces. Additionally, ensuring proper machine rigidity and workpiece fixturing is critical to preventing vibration-induced cracks.

Small-batch precision machining often fails due to inadequate process validation and lack of statistical process control. Without enough parts to establish stable processes, it’s easy to miss subtle variations. At Goldcattle, we use digital twins and virtual machining to validate processes before cutting any material, significantly reducing failure rates in small-batch production.

AI is revolutionizing precision machining through real-time adjustment of cutting parameters based on sensor feedback. Our AI systems can detect vibration, tool wear, and thermal changes, adjusting feeds and speeds automatically to maintain optimal cutting conditions. In 2025 testing, this improved surface quality consistency by 18% and reduced tool wear by 25%.

We adhere to ISO 9001:2000, AS9100 (aerospace), ISO 13485 (medical), and IATF 16949 (automotive) standards, with 100% inspection for critical parts and statistical process control (SPC) for high-volume production. Regular audits and continuous improvement programs ensure our processes remain at the highest standards.

Beyond 2026, we expect to see even greater integration of AI and machine learning, further advances in hybrid manufacturing (combining additive and subtractive processes), and increased focus on sustainable machining practices. The industry will continue to push the boundaries of precision, with nanoscale machining becoming more common for specialized applications.

Need Precision Machining Expertise for Your Project?

Whether you need precision components for aerospace, medical devices, electric vehicles, or 5G infrastructure, Goldcattle has the expertise and technology to deliver exceptional results. Our 18 years of experience and 300+ successful projects demonstrate our commitment to precision and quality.

Risk Warning

Precision machining requires professional technology and experience. Goldcattle recommends: Before large-scale production, conduct small-batch trial production verification to ensure processes and quality meet requirements.

Risk reduction recommendations:

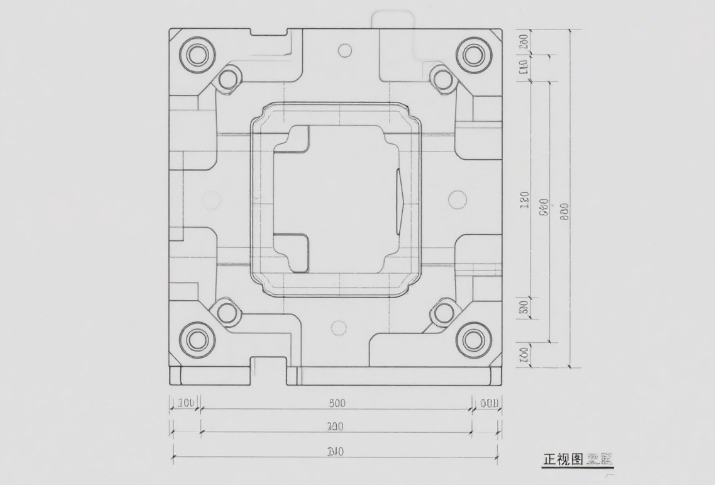

- Provide detailed technical requirements and drawings

- Clarify material properties and quality standards

- Require process documentation and inspection reports

- Establish clear acceptance standards and testing methods

- Consider sample development before large-scale production

Contact Goldcattle Precision Machining

Phone: +86-18150097490

Email: charlie@plasticmetalparts.com

Our engineering team will respond within 24 hours and provide professional technical consultation and quotation based on your specific requirements.