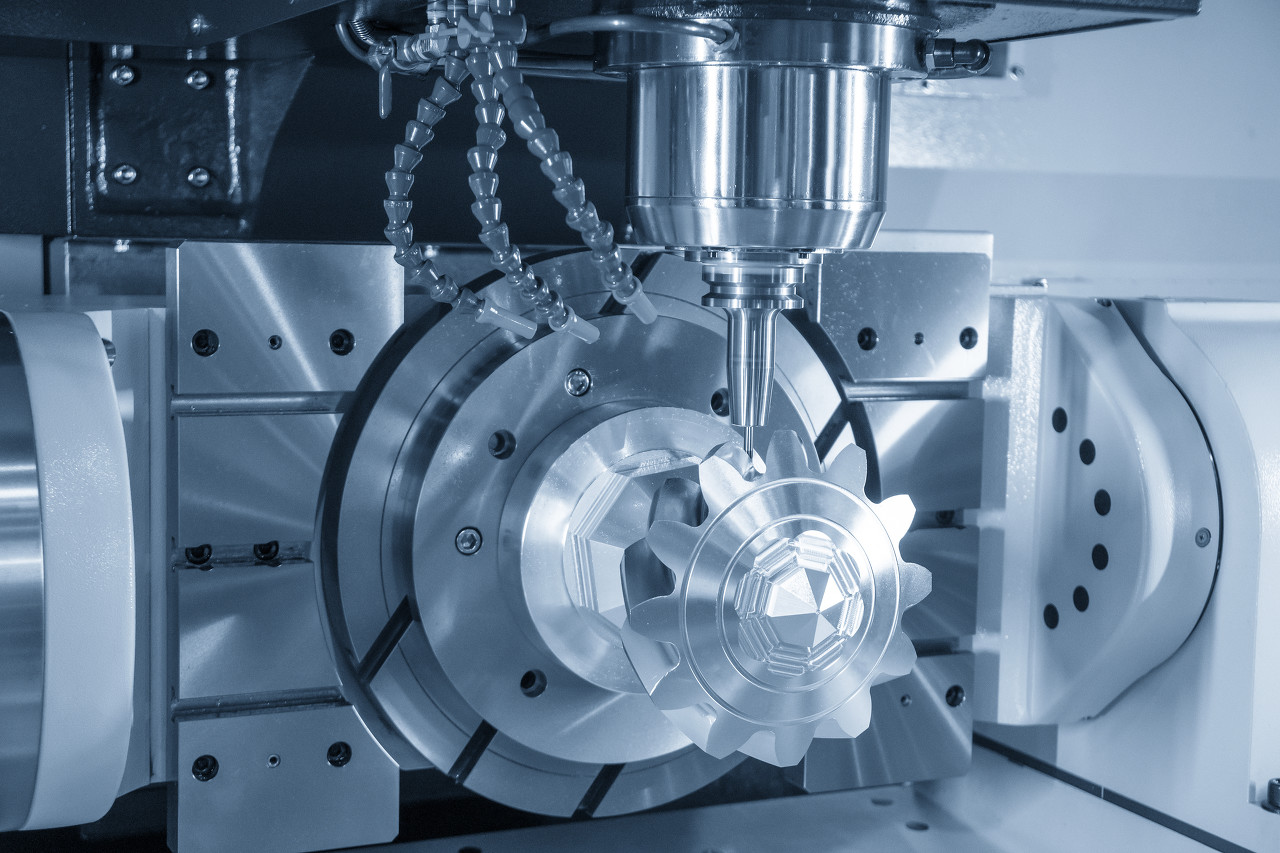

Basics Materials Processes Applications 2026 Trends Costs & Defects FAQ CNC Machining – What You Actually Need to Know So, What Exactly IS CNC Machining? CNC stands for Computer Numerical…

Answer Yes, brass is excellent for machining. Its combination of softness, high ductility, and self-lubricating properties (due to lead content in alloys like C36000) makes it ideal for precision machining….

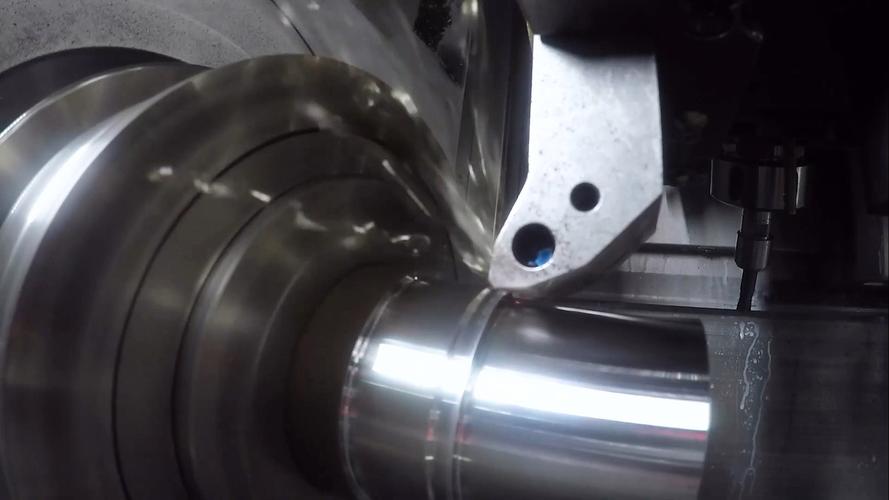

In the field of precision mechanical machining, step turning stands as a core technology, leveraging its unique geometric processing capabilities to become a critical technique for manufacturing complex shaft components….

If you need to apply for aluminum CNC machining services online, you can directly visit the official website of Xiamen GoldCattle Industry and Trade Co., Ltd. (https://www.xmgoldcattle.com/). Submit an online…

The Ugly Truth About CNC Machining Dude, let’s be real – CNC isn’t perfect. We’re breaking down the ACTUAL disadvantages that no sales guy will tell you about $500K+ 5-Axis…

Preventing rust on CNC stainless steel parts involves maintaining their passive oxide layer through material selection (e.g., 316 with molybdenum), post-machining treatments (passivation, electropolishing), avoiding surface damage during processing, using…