Answer

The core differences between CNC machining and stamping are as follows:

CNC machining uses computer – controlled cutting tools to cut raw materials (such as metals and plastics), achieving high – precision and complex – shaped subtractive manufacturing. It is suitable for small – batch customization, like aerospace parts.

Stamping uses molds and presses to form sheet materials (such as bending and punching), which belongs to additive manufacturing and is suitable for large – scale standardized production, like automotive outer shells.

Expansion

I. Processing Principles

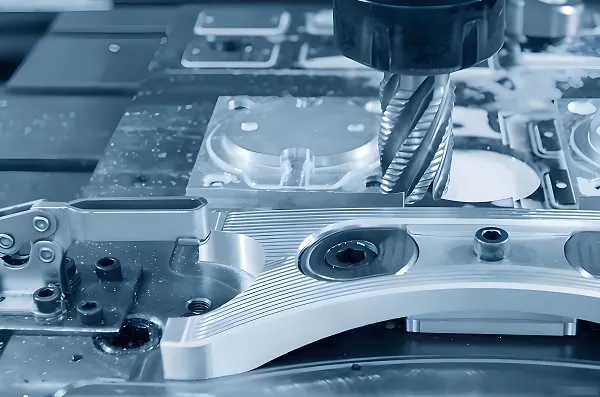

CNC Machining:

Technology type: Subtractive manufacturing (removing materials through milling, turning, drilling, etc.).

Core equipment: CNC milling machines, lathes, grinders, etc., relying on high – precision tool – path control.

Accuracy limit: Can reach ±0.001mm (such as the micron – level accuracy of medical implants).

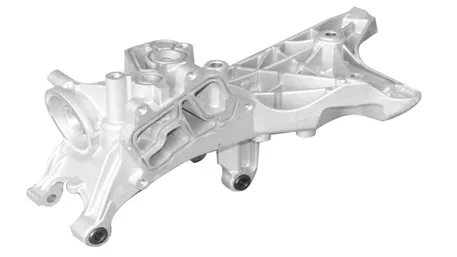

Stamping Processing:

Technology type: Forming manufacturing (applying pressure to sheet materials through molds to make them plastically deform).

Core equipment: Mechanical presses, hydraulic presses, in combination with customized molds (such as blanking dies, bending dies).

Accuracy range: Usually above ±0.1mm (affected by mold wear, suitable for non – precision parts).

II. Cost Structure

CNC Machining:

Pre – production cost: Low (no need for molds, only CAD programming required).

Unit cost: High (low material utilization rate, for example, the waste rate of aluminum block processing can reach 50%).

Economies of scale: Not obvious, suitable for small batches of 1 – 1000 pieces (such as prototype verification, high – end customization).

Stamping Processing:

Pre – production cost: Extremely high (mold design + manufacturing costs range from 100,000 to 1,000,000 yuan, with a cycle of 4 – 12 weeks).

Unit cost: Extremely low (when the batch exceeds 10,000 pieces, the cost per piece can be reduced to less than 0.1 yuan).

Economies of scale: Significant, suitable for mass production in the millions (such as mobile phone casings, beverage cans).

III. Design Flexibility

CNC Machining:

Geometric complexity: Almost unlimited (can process internal threads, undercuts, thin – walled parts).

Material compatibility: Covers all materials (metals, ceramics, composite materials, etc.).

Typical cases: Aero – engine blades , customized jewelry (fine carving).

Stamping Processing:

Geometric complexity: Limited (needs to follow the principle of “formability”, such as avoiding sharp angles and high draw ratios).

Material compatibility: Mainly suitable for metals with good ductility (such as low – carbon steel, aluminum alloy).

Typical cases: Automobile door frames (one – time stamping forming), heat sinks for electronic devices (array punching).

IV. Production Efficiency

CNC Machining:

Time per piece: From minutes to hours (for example, it takes 2 hours to process a titanium – alloy aerospace part).

Difficulty of automation: High (manual loading and unloading are required, and multiple process switches are needed for complex parts).

Suitable scenarios: Urgent orders (samples can be produced within 24 hours), R & D iteration (only need to adjust the program for design modification).

Stamping Processing:

Time per piece: Second – level (high – speed presses can reach 600 times/minute, such as producing screws).

Difficulty of automation: Low (fully automated production lines can be achieved with robots).

Suitable scenarios: Long – term stable orders (such as 10 million pieces of automotive seat brackets produced annually).

V. Application Fields

CNC Machining:

Aerospace (turbine discs, landing gear parts)

Medical (dental implants, surgical instruments)

Electronics (precision connectors, heat dissipation modules)

Stamping Processing:

Automobile manufacturing (body panels, engine brackets)

Home appliances (refrigerator casings, washing machine inner drums)

Daily necessities (beverage cans, tableware)

Decision – making Guide:

Choose CNC when the demand is for small batches, high complexity, and high added – value (such as satellite parts).

Choose stamping when the demand is for large – scale, low – cost, and standardized production (such as construction – used angle steel).

Compromise solution: Rapid tooling (3D – printed molds + small – tonnage stamping), suitable for medium – sized batches of 500 – 5000 pieces, with a cost 60% lower than traditional stamping.