Answer

The core difference between metal stamping and engraving lies in their technological essence: Stamping forms structural parts (e.g., car bodies) by deforming or separating metal through dies and presses, while engraving creates indentations by removing material with tools or lasers. The former is “pressure-forming,” the latter “subtractive engraving,” differing in functional structure vs. surface decoration.

Extended Response (Eight Key Dimensions, ~1500 words)

I. Technological Principles & Material Transformation Mechanisms

1. Metal Stamping’s Forming Logic

- Predominantly Plastic Deformation: Uses presses (5-2,000 tons) to drive punch-die sets, forcing metal sheets beyond their yield strength. Examples:

- Automotive door stamping: 2mm aluminum is drawn into curved panels via tensile dies, reshaping without volume change;

- Battery steel case stamping: Progressive dies sequentially punch, draw, and flange to form cylindrical shells.

- Secondary Separation Processes: Blanking dies fracture metal locally, e.g., stamping 0.5-5mm apertures in stainless steel filters.

2. Metal Engraving’s Subtractive Logic

- Diverse Material Removal Methods:

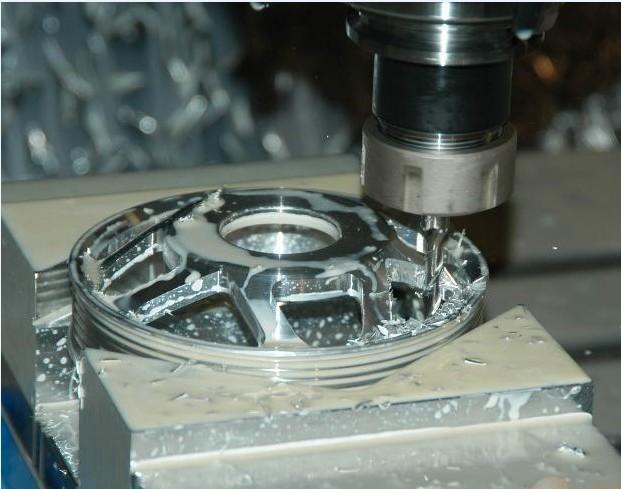

- Mechanical Engraving: CNC engravers use carbide tools (HRC≥60) to mill surfaces, e.g., carving 0.3mm-deep logos in 1mm brass plates;

- Laser Engraving: High-energy laser beams (50-200W) vaporize metal, enabling 0.05mm-wide micro-lines on titanium watch cases;

- Electrochemical Engraving: Corrodes anodic metal via electrolytes, ideal for high-precision patterns (e.g., circuit board markings).

- Typical Case: Coin engraving uses tools to mill relief patterns layer-by-layer, with 0.1-0.5mm groove depth and edge roughness Ra≤1.6μm.

II. Tooling, Equipment & Technical Parameters

| Comparison Dimension | Metal Stamping | Metal Engraving |

|---|---|---|

| Core Equipment | Mechanical/hydraulic presses, die heat treatment systems | CNC engravers, laser engravers, electrochemical workstations |

| Tool Types | Steel dies (punch+die, HRC58-62) | Carbide tools, fiber laser heads, electrochemical electrodes |

| Equipment Investment | Small stamping line (30 tons): ~$28,000; automotive line: >$1.4M | Small laser engraver (50W): ~$21,000; 5-axis CNC engraver: ~$113,000 |

| Key Parameters | Stamping speed: 10-1,000 strokes/min; pressure: 5-2,000 tons | Engraving speed: 50-500mm/min; laser power: 20-200W |

| Die/Tool Lifespan | Steel dies: 500k-1M strokes; carbide dies: 10M strokes | Mechanical tools: 500-1,000 pieces per tool; laser heads: no wear |

III. Material Suitability & Thickness Limits

1. Stamping’s Material & Thickness Range

- Material Requirements: High-ductility metals, including:

- Low-carbon steel (Q235): 0.5-4mm for structures (e.g., brackets);

- Aluminum alloy (5052): 0.3-2mm for phone casings;

- Copper alloy (H62): 0.1-1.5mm for electronic connectors.

- Thickness Constraints: Hydraulic presses handle up to 10mm steel, but energy consumption surges over 3mm (e.g., 5mm steel requires >800-ton presses).

2. Engraving’s Material & Thickness Flexibility

- Broad Material Compatibility:

- Hard metals: Titanium (TA2), stainless steel (304), even cemented carbide (YG8);

- Soft metals: Pure copper/aluminum for fine engraving (e.g., 0.03mm line width).

- Thickness Adaptability:

- Thin sheets excel: 0.1-3mm foils (e.g., 0.2mm stainless steel mesh engraving);

- Thick plates: Over 5mm, engraving depth caps at ~2mm (e.g., 10mm aluminum), with 3-5x longer processing time.

IV. Precision Control & Surface Quality

1. Stamping’s Dimensional Accuracy & Surface Features

- Dimensional Precision:

- General stamping: ±0.1-0.2mm (e.g., appliance casings);

- Precision stamping: ±0.03-0.05mm (e.g., electronic terminals), requiring high-precision dies (clearance ≤0.01mm).

- Surface Defects:

- Common issues: Die wear causes scratches (≤0.05mm depth), drawing wrinkles (ameliorated by blank holders);

- Burrs: Blanking edges have burrs ≤0.05mm (precision parts need secondary deburring).

2. Engraving’s Pattern Precision & Surface Finish

- Pattern Precision:

- Mechanical engraving: Line width ±0.02mm (e.g., watch scales);

- Laser engraving: ±0.01mm (e.g., microelectronic labels), minimum line width 0.03mm.

- Surface Quality:

- Laser engraving: Ra≤0.8μm, burr-free, ideal for mirror finishes (e.g., stainless steel nameplates);

- Mechanical engraving: Slight edge chipping (needs polishing), Ra≤1.6μm.

V. Production Efficiency & Batch Adaptability

1. Stamping’s Mass-Production Advantage

- High-Speed Batch Production:

- Progressive die stamping: E.g., terminal production at 1,000 strokes/min (1,000 parts/hour);

- Tooling changeover: 8-12 hours for automotive panel dies, suitable for >100k units (unit cost <$0.7).

- Efficiency Bottleneck: For low batches (<1k), die costs skyrocket (e.g., $7,000 die → $70 unit cost for 100 parts).

2. Engraving’s Flexible Production

- Low-Volume & Customization:

- Laser engraving: Design changes via programming, ideal for 50-500 custom pieces (e.g., personalized coins, 1-5min/part);

- Mechanical engraving: Programming dominates for small batches (e.g., 100 metal signs: 2hr programming + 3hr production).

- Efficiency Gap: Stamping 100k phone frames takes 5 days; engraving the same takes >150 days (8hr/day).

VI. Functional Application Scenarios

1. Stamping for Structural Parts

- Automotive: Body panels (doors, hoods), chassis brackets (stamped+welded);

- Electronics: Phone mid-frames (6061 aluminum stamping), battery steel cases (0.3mm stainless steel drawing);

- Appliances: Refrigerator liners (0.8mm galvanized steel drawing), washing machine counterweights (cast iron stamping).

2. Engraving for Decoration & Marking

- Luxury Goods: Watch dial scales (laser engraving), jewelry logos (mechanical engraving);

- Industrial Marking: Medical device serial numbers (electrochemical engraving, tamper-proof), tool anti-slip textures (laser-engraved mesh);

- Cultural Products: Metal bookmark patterns (0.5mm copper engraving), commemorative coin reliefs (engraved dies for stamping).

VII. Cost Structure & ROI

1. Stamping’s Cost Model

- Upfront Investment:

- Die costs: Simple dies (e.g., washers) ~$1,400; complex progressive dies (e.g., connectors) $70,000-$280,000;

- Equipment: 30-ton press+die ~$28,000; automotive stamping lines (with robots) $1.4M-$4.2M.

- Economies of Scale: For 100k units, stamping costs ~$0.14-$0.7/part (die amortization $0.07-$0.28), vs. engraving’s $2.8-$7/part.

2. Engraving’s Cost Advantages

- Low Upfront Costs:

- Benchtop laser engraver (50W) ~$7,000, ideal for small trials (100 samples, $1.4-$4.2/part);

- No die costs; design changes take 10min (e.g., logo font updates).

- Cost Disadvantage: Over 5k units, engraving costs ($2.1/part) exceed stamping ($0.42/part) due to equipment bottlenecks.

VIII. Post-Processing & Environmental Requirements

1. Stamping Post-Processing

- Deburring: Electrolytic deburring ($0.014-$0.07/part), sandblasting (rough surfaces);

- Stress Relief: Thick parts need annealing (e.g., 45# steel at 200°C for 2hr);

- Surface Protection: Electroplating (zinc/nickel), painting (automotive coatings 80-120μm thick).

2. Engraving Surface Treatment

- Anti-Oxidation: Exposed surfaces require electroplating (e.g., 5-10μm nickel on stainless steel);

- Wear Resistance: Laser-engraved anti-slip textures can be anodized (aluminum, 10-20μm oxide layer);

- Environmental Comparison: Stamping oil mist needs VOCs treatment; engraving produces minimal metal dust (laser) with no chemical pollution.

IX. Integrated Process Cases

- Stamp Then Engrave:

- Metal keychains: Stamp 0.8mm brass blanks → laser-engrave logos → electroplate;

- Watch cases: Stamp 316L stainless steel structures → 5-axis CNC engrave bezel scales (±0.02mm) → polish.

- Engrave to Aid Stamping:

Pre-engrave positioning grooves on sheets to boost stamping accuracy by 30%.

X. Decision Guide

- Choose Stamping for:

- High volumes (>10k), functional structures (e.g., load-bearing brackets);

- Materials >0.5mm needing plastic deformation (drawing, bending).

- Choose Engraving for:

- Low-volume customization (<500), surface decoration/marking (e.g., personalized gifts);

- High-precision patterns (±0.05mm), hard materials (titanium) unsuitable for stamping.

Through multi-dimensional comparison, metal stamping and engraving complement each other: The former dominates mass-produced functional parts, while the latter excels in personalized surface processing, together supporting manufacturing needs from industrial components to high-end customization.