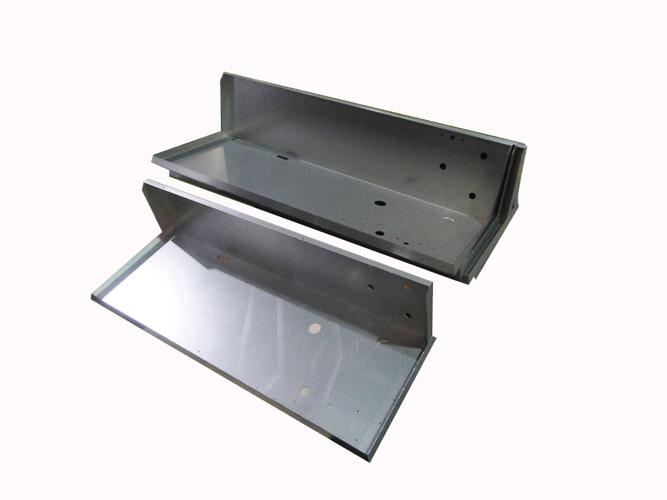

The core difference between sheet metal parts and machined parts lies in raw material form and processing methods: sheet metal parts are “shaped” from thin metal sheets through cutting, bending, etc., while machined parts are “carved” from solid metal blocks using CNC machines. Simply put, one is like “paper folding,” and the other is like “sculpting.”

1. Material Form: Thin Sheets vs. Solid Blocks

Sheet metal parts use thin metal sheets (0.5-6mm thick), such as aluminum sheets of soda cans or steel sheets for refrigerator casings, which are ideal for bending and stamping. For example, the curvature of car doors is “bent” into shape by bending machines. Machined parts use solid metal blocks, which can be over 6mm thick—even tens of centimeters. Aerospace turbine blades, for instance, are “hollowed out” from titanium alloy blanks.

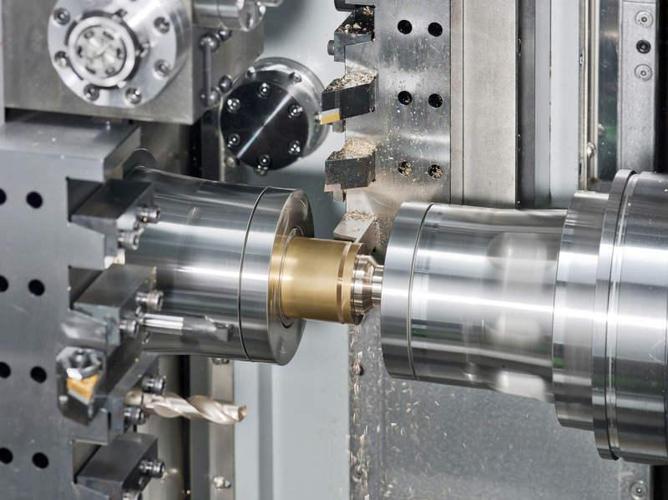

2. Processing Methods: Manual-like vs. Computer-Controlled

Sheet metal processing is more like “handiwork”: cutting sheets with laser cutters, bending angles with bending machines, then welding and assembling. Air conditioner outer casings, for example, are made by bending and joining thin sheets. Machined parts rely entirely on CNC machines—like computer-controlled “super carving knives”—removing excess material through milling and drilling. Mobile phone middle frames, for instance, have holes and slots precise to 0.01mm.

3. Precision & Details: Adequate vs. Extreme Precision

Sheet metal parts typically have a tolerance of ±0.1-0.2mm, suitable for scenarios like equipment casings. Machined parts, thanks to CNC, can achieve ±0.01mm tolerance (1/10 the thickness of a hair), meeting needs like precision interfaces for medical devices. However, sheet metal parts can also improve precision through polishing or adding reinforcing ribs.

4. Cost & Efficiency: Mass Production vs. Customization

Sheet metal excels in low-cost mass production. After mold opening, dozens of identical sheet metal brackets can be stamped per minute, with a single unit costing just a few cents for a batch of 1,000. For small batches or complex designs, machining is better. Making 5 prototypes, for example, is cheaper with CNC milling—it skips mold costs and delivers faster.

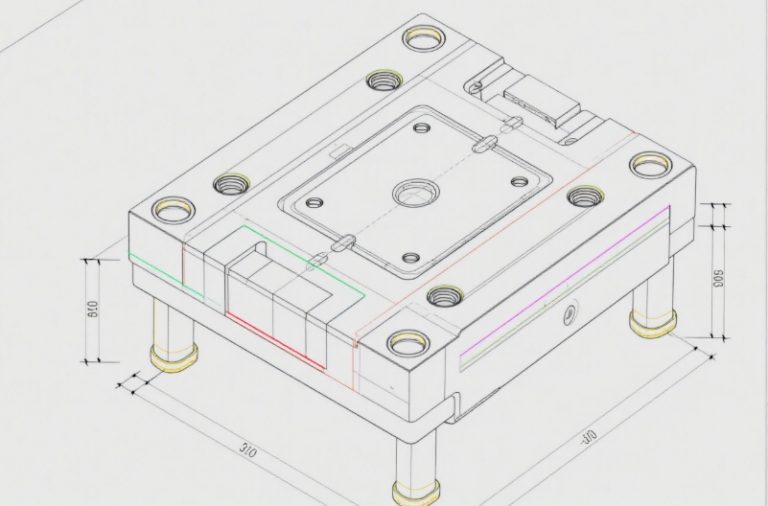

5. Design Flexibility: 2D Creativity vs. 3D Complexity

Sheet metal shines in 2D “creativity”: bending right angles, stamping louver cooling holes, or stretching to form curved surfaces (like the curvature of car hoods). But 3D complex structures—with inner cavities, threads, or cross holes—require machining. Drone motor mounts, which need to fit motors, bearings, and wiring, can only be “sculpted” into such 3D forms via machining.

FAQ

Q: If material thickness exceeds 6mm, must we use machining?

A: Not necessarily. 6mm is a rough threshold. Thick sheet metal (6-12mm) is possible but harder to bend and more costly—machining may be more economical here.

Q: Which is cheaper for small-batch production?

A: For small batches (e.g., under 10 units), machining saves mold costs. For batches over 100, sheet metal becomes cheaper after mold opening.

Q: Can sheet metal meet ±0.05mm tolerance requirements?

A: Unlikely. Sheet metal’s upper precision limit is around ±0.1mm. For ±0.05mm, machining is better—CNC handles this easily.

Q: Do curved parts always require machining?

A: No. Simple curves (e.g., shallow curved casings) can be made via sheet metal stretching or roll bending. Complex 3D curves (e.g., concave inner cavities) need machining.

Professional Customization Service Recommendation

If you’re struggling to choose between sheet metal and machining, check out Xiamen Goldcattle’s solutions! As a national high-tech enterprise with 26 years of experience, they offer one-stop customization from sheet metal stamping and CNC precision machining to 3D printing and injection molding.

Whether it’s high-strength sheet metal for auto parts or ±0.005mm precision machined parts for medical devices, their 5-axis machining equipment and SGS/ISO 9001 certification ensure quality. They support customization from drawings or samples—small watch core parts to large equipment casings, they’ve got you covered.

Leave a message with your part requirements (material/tolerance/batch size) now to get a free process plan and quotation reference. Let their expert team help you pick the right processing method!