- Geometric shape: The object’s outline (e.g., a cube’s edges, a human face’s curves).

- Topological relationships: How parts of the object connect (e.g., a chair’s legs attached to its seat).

- Attribute information: Visual properties (color, texture, transparency) and physical characteristics (density, rigidity, thermal conductivity).

1. Core Components of a 3D Model (What Makes It “3D”?)

|

Component

|

Definition

|

Key Role

|

|

1. Geometric Primitive

|

The basic building blocks (e.g., points, lines, triangles, polygons, curves) that form the model’s shape.

|

Defines the model’s physical outline —e.g., a sphere is made of hundreds of triangular “facets.”

|

|

2. Topology

|

The logical connection between primitives (e.g., which edges of a polygon attach to another polygon).

|

Ensures the model is “watertight” (no gaps/overlaps) for 3D printing or simulation—critical for industrial parts.

|

|

3. UV Mapping

|

A 2D “unwrap” of the model’s surface that maps 2D textures (e.g., wood grain, metal sheen) to 3D geometry.

|

Adds realistic visual detail—e.g., a 3D model of a wooden table uses UV mapping to align wood texture with the table’s surface.

|

|

4. Metadata

|

Additional data tied to the model (e.g., dimensions, material type, author, creation date).

|

Enables collaboration (e.g., engineers sharing part specs) and workflow integration (e.g., 3D printers reading size data).

|

- Geometric primitives (rectangular polygons for the screen, curved polygons for the edges);

- Topology (screen edges attached to the phone’s frame, no gaps);

- UV mapping (glass texture on the screen, metal texture on the frame);

- Metadata (150mm x 75mm x 7mm dimensions, “ABS plastic” material tag).

2. Classification of 3D Models (By Type & Purpose)

2.1 By Modeling Technique (Core Methods)

|

Model Type

|

Creation Principle

|

Accuracy

|

Best For

|

|

Polygon Mesh Model

|

Built from connected polygons (triangles, quadrilaterals) forming a “mesh” of surfaces.

|

Moderate-High (depends on polygon count)

|

Visualization (Film and television characters, games assets), 3D printing prototypes—most common type (used in Blender, Maya).

|

|

NURBS Model

|

Based on mathematical curves (Non-Uniform Rational B-Splines) that define smooth, precise surfaces.

|

High (mathematically exact)

|

Industrial design (car bodies, aircraft parts), CAD engineering—used in SolidWorks, Rhino.

|

|

Voxel Model

|

Composed of 3D “pixels” (voxels: volume elements) that fill the model’s space (like a 3D grid).

|

Low-Moderate

|

Medical imaging (CT/MRI scans), 3D scanning of organic objects (e.g., fossils)—used in 3D Slicer, MagicaVoxel.

|

|

Parametric Model

|

Defined by adjustable parameters (e.g., “cylinder height = 100mm, radius = 20mm”)—changes to parameters update the model automatically.

|

High

|

Product design (customizable parts), architecture (modular buildings)—used in Fusion 360, Revit.

|

2.2 By Application Scenario (Practical Use Cases)

|

Category

|

Key Requirement

|

Example Models

|

|

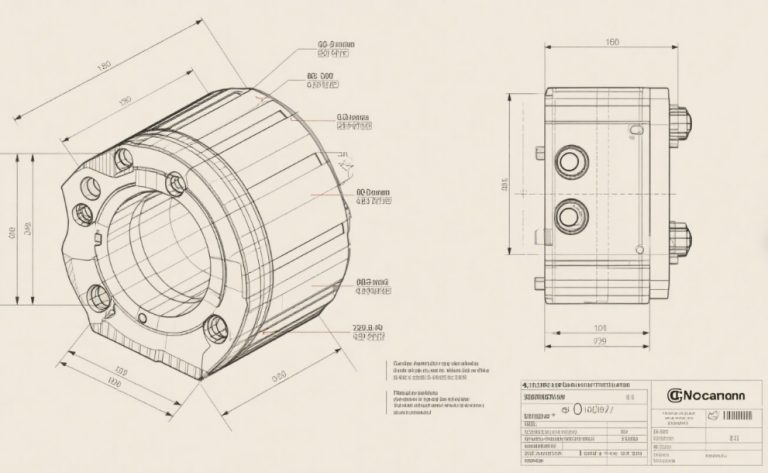

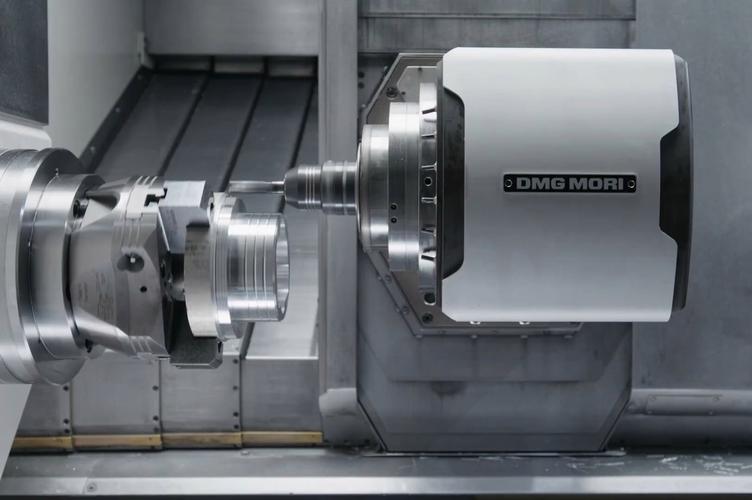

Industrial/Engineering

|

Precision (±0.01mm), compatibility with manufacturing tools.

|

Car engine components (CAD models), HVAC system schematics (BIM models).

|

|

Entertainment (影视 / Game)

|

Realism, low file size (for real-time rendering).

|

Movie characters (e.g., “Avatar” Na’vi models), game environments (e.g., Fortnite maps).

|

|

Architecture/Construction

|

Scale accuracy, integration with structural analysis.

|

Building exteriors (BIM models), interior layouts (3D floor plans).

|

|

Medical/Healthcare

|

Anatomical accuracy, compatibility with imaging data.

|

Patient-specific organ models (from MRI scans), dental crown prototypes.

|

|

Educational/Research

|

Simplified geometry, focus on concept visualization.

|

3D models of DNA strands, planet models for astronomy lessons.

|

3. How 3D Models Are Created (Standard Workflow)

Step 1: Define Requirements & Concept

- Clarify goals: Is the model for 3D printing (needs watertight geometry) or VR (needs low polygon count)?

- Gather references: Use photos, sketches, or physical objects (e.g., a hand-drawn sketch of a lamp) to guide shape.

Step 2: Choose Modeling Tool & Technique

- For polygon models (visualization): Blender (free), Maya (professional).

- For NURBS/CAD models (engineering): SolidWorks (industrial), Rhino (design).

- For parametric models (customizable parts): Fusion 360 (hobbyists/engineers), Revit (architecture).

Step 3: Build the Base Geometry

- Polygon modeling: Start with a primitive (e.g., a cube), then extrude (stretch), subdivide (add detail), or sculpt (shape like clay) to refine the form.

- NURBS modeling: Draw 2D curves (e.g., a car’s side profile), then loft (stretch curves into 3D surfaces) to create smooth shapes.

- 3D scanning (alternative): For physical objects, use a 3D scanner (e.g., EinScan) to capture geometry directly, then clean up the scan data in software (e.g., Meshlab).

Step 4: Add Details & Attributes

- Topology optimization: Fix gaps/overlaps (use “sew” tools in Blender) to make the model watertight (critical for 3D printing).

- Texturing: Apply UV mapping, then add textures (e.g., a concrete texture for a building model) using software like Substance Painter.

- Material assignment: Define physical properties (e.g., “glass” = transparent, “steel” = reflective) for rendering or simulation.

Step 5: Validate & Export

- Check accuracy: Use measurement tools (e.g., in SolidWorks) to verify dimensions match specs.

- Optimize for use case: Reduce polygon count (for real-time apps) or export as STEP/IGES (for CAD manufacturing).

- Export to standard format:

-

- Visualization: .OBJ, .FBX (compatible with Blender/Maya).

-

- 3D printing: .STL, .3MF (readable by slicers like Cura).

-

- Engineering: .STEP, .IGES (universal CAD formats).

4. 3D Models vs. Related Concepts (Avoid Confusion)

|

Term

|

Relationship to 3D Models

|

Key Difference

|

|

3D Printing

|

3D models are the “digital blueprint” for 3D printing—printers convert .STL/.3MF models into physical objects.

|

3D printing is a manufacturing process; 3D models are the digital input for that process.

|

|

CAD (Computer-Aided Design)

|

CAD is a toolset for creating 3D models (mostly industrial/engineering models).

|

CAD is software/process; 3D models are the output of CAD.

|

|

VR/AR

|

VR/AR rely on 3D models to create immersive environments (e.g., a VR house tour uses a 3D model of the house).

|

VR/AR is an experience platform; 3D models are the content that powers the experience.

|

|

2D Drawings

|

2D drawings are flat representations; 3D models can generate 2D views (e.g., a top-down blueprint from a 3D house model).

|

2D lacks depth; 3D models capture all three dimensions (X/Y/Z axes).

|

5. Common Myths About 3D Models

Myth 1: “3D models must have millions of polygons to be good.”

Myth 2: “3D scanning creates perfect 3D models automatically.”

Myth 3: “All 3D models work for 3D printing.”

Myth 4: “3D models are only for professionals.”

6. The Value of 3D Models in Industry & Society

6.1 Industrial Manufacturing

- Reduced prototyping costs: Testing a digital 3D model (via simulation) costs 90% less than building a physical prototype.

- Customization: Parametric 3D models enable mass customization (e.g., custom shoe soles 3D printed from user foot scans).

6.2 Healthcare

- Precision medicine: Patient-specific 3D models of tumors or organs let surgeons practice procedures before surgery—reducing operation time by 30% (per Johns Hopkins research).

- Prosthetics: 3D models of limbs enable low-cost, custom prosthetics (e.g., e-NABLE’s open-source 3D printed hands).

6.3 Architecture & Construction

- BIM (Building Information Modeling): 3D models integrate structural, electrical, and plumbing data—reducing construction errors by 20% (per McKinsey).

- Sustainability: 3D models simulate energy use (e.g., sunlight exposure) to optimize building efficiency.

6.4 Entertainment

- Immersive experiences: 3D models of characters and environments power modern movies (e.g., “Dune”’s sandworms) and VR games (e.g., “Half-Life: Alyx”).

7. Future Trends in 3D Modeling

- AI-Assisted Modeling: Tools like NVIDIA Instant NeRF generate 3D models from 2D photos in minutes (vs. hours of manual work).

- Real-Time Collaboration: Cloud-based tools (e.g., Onshape) let teams edit 3D models simultaneously—accelerating design workflows.

- Generative Design: AI generates optimized 3D models based on constraints (e.g., “lightweight but strong enough for a drone frame”)—used by Airbus to reduce part weight by 40%.