The stamping procedure is a systematic manufacturing process that shapes flat metal sheets into desired parts using dies and presses. It involves a sequence of steps: material preparation, die setup, feeding metal into the press, and performing operations like cutting, bending, or forming via die contact. The process ensures high-volume production of consistent, precise parts, with post-processing for finishing and quality checks.

Detailed Analysis of the Stamping Procedure

1. Core Stages of the Stamping Procedure

The stamping process follows a structured workflow to transform raw metal into finished parts, ensuring efficiency and quality at each step:

-

Stage 1: Material Preparation

Raw metal sheets or coils are inspected and prepared to meet specifications. Materials (steel, aluminum, copper) are selected based on part requirements (strength, corrosion resistance). Coils are uncoiled, straightened to remove curvature, and cut into blanks (flat sheets) of appropriate size using decoilers and blanking machines. For example, automotive body parts use 0.8–1.2mm thick mild steel blanks, while electronics contacts use 0.1–0.3mm thick copper strips. Surface cleaning (degreasing with alkaline solutions) removes oils or contaminants to prevent die damage and part defects. -

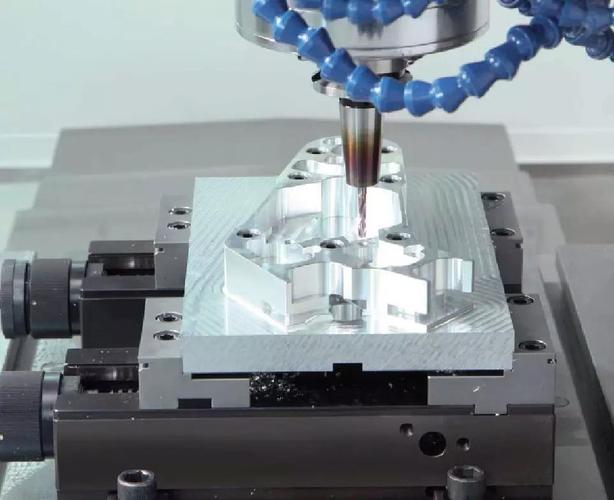

Stage 2: Die Design & Setup

Dies (custom tooling) are designed using CAD/CAM software to match part geometry, incorporating features like punches (upper tools) and dies (lower tools) for cutting or forming. Dies are fabricated from tool steel (H13, D2) for durability, with heat treatment to 55–60 HRC for wear resistance. Setup involves mounting dies onto the press bed, aligning them with precision (±0.02mm) using guide pins, and adjusting clearances between punches and dies to ensure clean cuts or proper forming. For progressive dies, multiple stations are aligned sequentially to perform operations in one pass. -

Stage 3: Metal Feeding & Press Operation

The prepared metal (blank or coil) is fed into the press. For coil-fed systems, automated feeders advance material at precise intervals (synchronized with press cycles) to ensure accurate positioning. Mechanical or hydraulic presses apply force (10–3,000 tons) to close the dies, performing operations:- Cutting: Blanking (producing flat parts), piercing (creating holes), or trimming (removing excess material) using sharp die edges.

- Forming: Bending (angles), drawing (hollow shapes), or embossing (raised features) by reshaping metal without cutting.

Press speed varies by part size: 10–100 strokes per minute (SPM) for large automotive parts, 100–1,000 SPM for small electronics components.

-

Stage 4: Post-Processing & Inspection

Stamped parts are removed from dies, with excess material (scrap) separated for recycling. Post-processing steps include:- Deburring: Removing sharp edges via tumbling, brushing, or laser trimming to prevent assembly injuries.

- Surface Treatment: Plating (zinc, nickel), painting, or powder coating for corrosion resistance or aesthetics (e.g., automotive trim).

- Heat Treatment: Annealing or tempering for high-strength steels to reduce brittleness (e.g., chassis brackets).

Inspection uses calipers, CMMs, or vision systems to verify dimensions (±0.05mm for general parts, ±0.01mm for precision components) and check for defects like cracks or uneven forming.

2. Key Stamping Operations & Their Roles

Different operations within the stamping procedure address specific part requirements:

- Blanking: Cuts a flat part (blank) from a larger sheet, forming the base shape for subsequent processing. Used for simple parts like washers or bracket blanks, with die clearances of 5–10% of material thickness to ensure clean edges.

- Piercing: Creates holes, slots, or notches in the blank using a punch and die. Critical for parts requiring fasteners (e.g., electrical panels with mounting holes) or fluid flow (e.g., radiator fins with cooling slots).

- Bending: Uses punch and die to fold metal along a straight axis, forming angles (90°, 135°) or channels. Springback (elastic recovery) is compensated by over-bending (e.g., bending to 92° for a 90° final angle) and using proper die radii (1–3× material thickness).

- Drawing: Transforms flat blanks into hollow parts (cans, enclosures) by stretching metal over a punch into a die cavity. Deep drawing (height > diameter) requires multiple passes with annealing between steps to relieve stress, preventing tearing in materials like aluminum or stainless steel.

- Embossing: Creates raised or recessed patterns (logos, textures) by pressing metal between a male and female die. Enhances aesthetics (consumer goods) or adds strength (structural ribs in brackets).

3. Material Considerations in Stamping

Material properties directly influence stamping success, dictating die design and press parameters:

- Formability: Ductile materials (aluminum 3003, mild steel) bend and draw easily, while brittle materials (high-carbon steel, titanium) require slower speeds and larger die radii to avoid cracking. Formability is measured by the percentage elongation (e.g., 30% for aluminum vs. 15% for high-carbon steel).

- Thickness: Thin sheets (<1mm) need precise feeding to prevent wrinkling, while thick sheets (>3mm) require higher press tonnage and stronger dies. For example, stamping 5mm steel brackets needs 500+ ton presses, vs. 50-ton presses for 0.5mm copper contacts.

- Surface Finish: Smooth materials (cold-rolled steel) reduce die wear and improve part appearance, while hot-rolled steel (rougher surface) may require additional cleaning to prevent die contamination.

- Alloy Selection: HSLA steel offers strength for automotive chassis without sacrificing formability; brass provides conductivity for electrical parts; stainless steel 316 resists corrosion in marine applications.

4. Equipment & Tooling Variations

Stamping equipment and dies are tailored to production volume and part complexity:

-

Press Types:

- Mechanical Presses: Use flywheels for high-speed, high-volume production (100–1,000 SPM), ideal for electronics and hardware.

- Hydraulic Presses: Offer slower, controlled force (10–50 SPM) for thick materials or deep drawing, used for automotive body parts.

- Servo Presses: Combine speed and precision with programmable force profiles, suitable for complex parts requiring variable pressure.

-

Die Types:

- Progressive Dies: Perform multiple operations (piercing → bending → blanking) in one pass, maximizing efficiency for high-volume parts (e.g., washers, connectors).

- Transfer Dies: Move parts between separate dies via robots, handling large or complex parts (e.g., automotive fenders) that progressive dies can’t accommodate.

- Compound Dies: Combine blanking and piercing in one station, producing parts with tight hole-to-edge tolerances (e.g., gear blanks).

5. Industry-Specific Procedure Adaptations

Stamping procedures adapt to meet sector-specific demands:

- Automotive: High-volume lines use coil-fed progressive dies with automated inspection, producing 10,000+ body panels daily. Hot stamping of boron steel (1,500 MPa strength) for crash components involves heating blanks to 900°C before forming.

- Electronics: Precision stamping of 0.1mm copper contacts uses fine blanking dies for burr-free edges, ensuring reliable electrical connections in smartphones and sensors.

- Aerospace: Low-volume, high-precision parts (titanium brackets) use hydraulic presses with custom dies, incorporating in-process monitoring to detect defects in critical components.

- Appliances: Deep drawing of stainless steel (e.g., dishwasher tubs) requires lubricated dies and multi-stage forming to avoid galling (material transfer between die and part).

The stamping procedure’s flexibility—from simple cutting to complex forming—enables mass production of diverse parts, balancing precision, speed, and cost across industries. By optimizing material selection, die design, and press operations, manufacturers consistently produce high-quality components for automotive, electronics, and beyond.