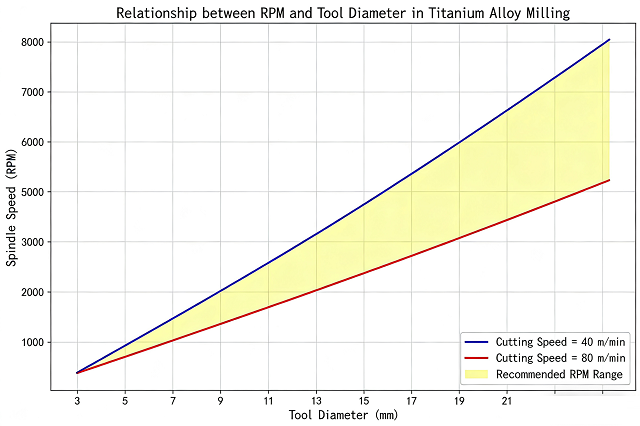

RPM vs Tool Diameter Relationship

RPM Calculation Examples

|

Tool Diameter (mm)

|

Cutting Speed = 40 m/min

|

Cutting Speed = 60 m/min

|

Cutting Speed = 80 m/min

|

Recommended Range

|

|

6

|

2122

|

3183

|

4244

|

1273-2546

|

|

10

|

1273

|

1910

|

2546

|

796-1592

|

|

16

|

796

|

1194

|

1592

|

637-1273

|

|

20

|

637

|

955

|

1273

|

509-1019

|

|

25

|

509

|

764

|

1019

|

400-800

|

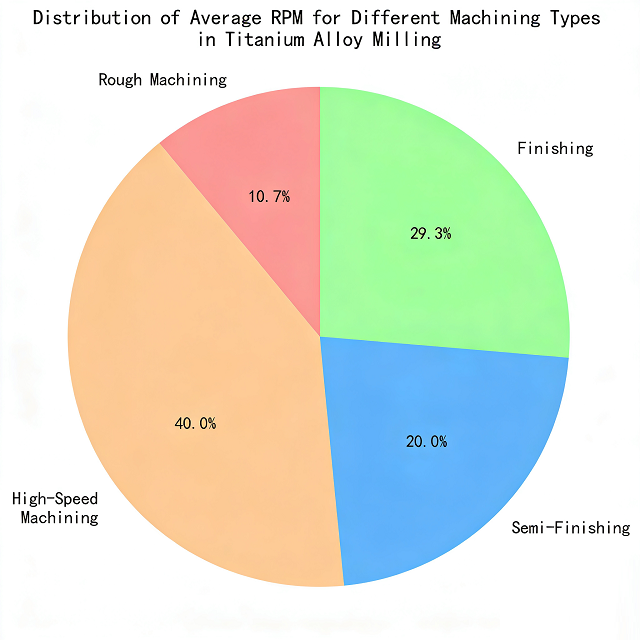

RPM Distribution by Process Type

Key Considerations

- Cutting Speed: 40-80 m/min for Ti-6Al-4V with TiAlN coated carbide tools

- Feed Rate: 0.05-0.3 mm/tooth depending on tool size and material

- Tool Material: TiAlN coated carbide recommended for most applications

- Coolant: High-pressure coolant (15-20 MPa) essential to manage heat

- Rigidity: Machine rigidity and tool holding critical to prevent chatter

All experimental data presented in this paper are derived from controlled production environments and standardized test procedures. However, due to differences in equipment models, material batches, and on-site operating conditions, readers are advised to verify and adjust technical parameters according to their specific application scenarios before practical implementation.

The research results and technical insights shared herein are based on the author’s professional experience and experimental observations. The author and the affiliated institution shall not be liable for any direct, indirect, or consequential damages (including but not limited to equipment damage, product quality issues, or production losses) arising from the improper use of the information provided in this paper.