1、Answer

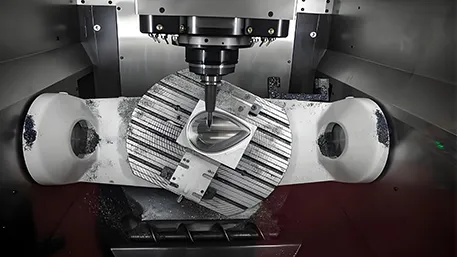

People use CNC (Computer Numerical Control) for high-precision, repeatable, and efficient manufacturing of complex parts. It automates machining processes (e.g., milling, turning, drilling) using computer programs, reducing human error, increasing production speed, and enabling intricate designs in industries like aerospace, automotive, and electronics.

2、Expansion

Key Advantages Driving CNC Adoption

-

Unmatched Precision and Consistency

- CNC machines achieve tolerances as tight as ±0.001 mm (e.g., in medical device components), far exceeding manual machining capabilities. For example, a CNC lathe can produce 10,000 identical engine pistons with <0.005 mm variation in diameter, critical for aerospace turbine components.

- Repeatability ensures batch production uniformity, essential for assembly-line compatibility (e.g., automotive transmission parts).

-

Complex Geometry Capability

- 3-axis to 5-axis CNC systems can machine intricate shapes like helical gears, turbine blades, or medical implants with lattice structures, which are impossible or time-consuming to create manually. For instance, 5-axis milling can carve a prosthetic hip socket with internal curves and surface textures in one setup, reducing manual labor by 70%.

-

Efficiency and Cost Savings

- ** lights-out manufacturing** (24/7 operation with minimal human supervision) boosts productivity. A CNC mill running overnight can complete 80 parts vs. 20 by a manual machinist in the same time.

- Reduced material waste: Advanced CAM software optimizes toolpaths to minimize scrap. For example, cutting a titanium aerospace bracket on a CNC reduces waste by 30% compared to traditional methods.

-

Flexibility and Scalability

- Quick reprogramming allows seamless switching between part designs. A single CNC machine can produce prototype parts in the morning and switch to mass production of a different component by afternoon, ideal for low-volume/high-mix industries like custom robotics.

- Scalable from prototyping (e.g., machining a single aluminum drone frame) to large-scale production (e.g., fabricating 100,000 plastic injection molds).

-

Safety and Reduced Labor Intensity

- Automates dangerous tasks (e.g., cutting hard metals at high speeds), minimizing operator exposure to hazards. For example, CNC plasma cutters handle high-temperature metal fabrication without human intervention.

- Reduces reliance on highly skilled labor for basic operations, though programming expertise remains critical.

Industry-Specific Applications

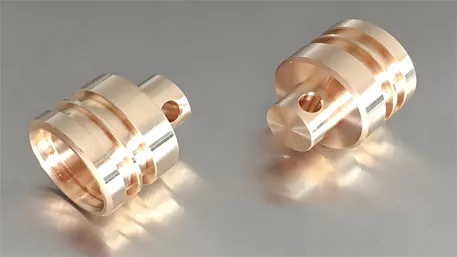

- Aerospace: Machining lightweight titanium alloy aircraft frames with 0.01 mm precision for fuel efficiency.

- Medical: Producing patient-specific spinal implants via CNC milling of cobalt-chrome alloys, guided by MRI-derived CAD models.

- Electronics: Fabricating micro-miniature connectors (e.g., 0.3 mm-thick pins for USB-C ports) using Swiss-type CNC lathes.

- Art and Prototyping: Artists and engineers use CNC routers to carve complex wooden sculptures or 3D-printed mold masters with sub-millimeter detail.

Challenges and Considerations:

While CNC offers vast benefits, it requires significant upfront investment (e.g., a 5-axis mill costs $200k–$1M) and expertise in CAD/CAM software. Small businesses may start with 3-axis machines for simpler parts, scaling up as demand grows. Despite these hurdles, CNC remains indispensable for modern manufacturing, driving innovation in precision and speed across sectors.

While CNC offers vast benefits, it requires significant upfront investment (e.g., a 5-axis mill costs $200k–$1M) and expertise in CAD/CAM software. Small businesses may start with 3-axis machines for simpler parts, scaling up as demand grows. Despite these hurdles, CNC remains indispensable for modern manufacturing, driving innovation in precision and speed across sectors.