Before exploring why CNC (Computer Numerical Control) milling is so expensive, we first need to gain a deeper understanding of the core principles of the technology, the unique advantages it offers, and the outstanding characteristics of the milled products.CNC milling, as an important part of modern precision manufacturing, has an unrelenting quest for technological accuracy, efficiency and flexibility behind its high cost.

1. Principle and technical advantages of milling

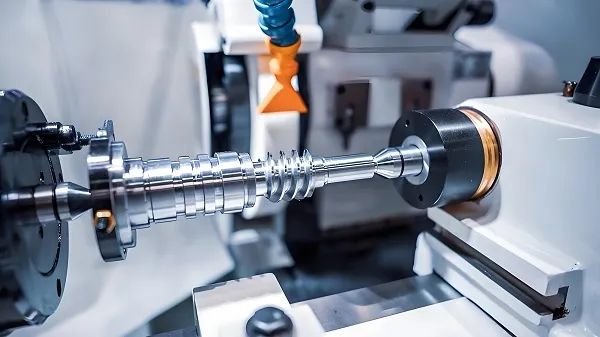

CNC milling is a machining process that cuts the workpiece layer by layer by means of a rotating tool. This process is precisely controlled by a computer program that ensures an accurate machining path. Parameters such as tool selection, cutting speed and feed are carefully calculated to achieve optimal machining results. This technology is not only capable of processing complex geometric shapes, but also realizes high-precision detail engraving on materials, which is difficult to compare with traditional manual or simple mechanical processing.

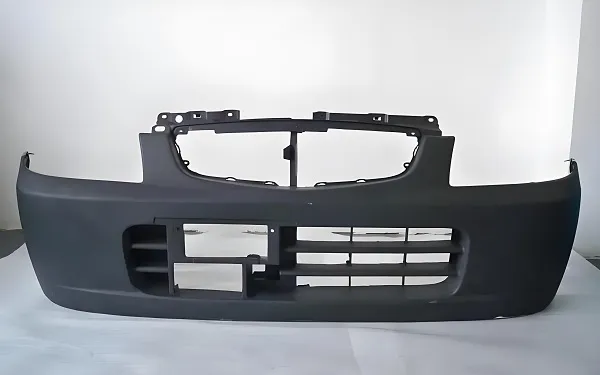

The technical advantages of CNC milling are mainly reflected in the following aspects: first, high precision, able to meet the micron-level machining requirements; second, high efficiency, through automated operations to significantly shorten the production cycle; third, flexibility, can be easily adapted to different materials, shapes and sizes of machining needs; fourth, repeatability, to ensure that each batch of products can maintain consistent quality. These advantages make CNC milling in aerospace, medical equipment, automobile manufacturing and other high-end manufacturing areas occupy an important position.

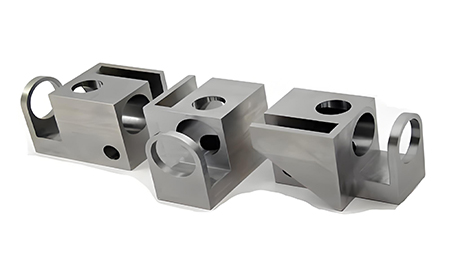

2. Characteristics of milled products

Products produced by CNC milling often have excellent surface finish, precise dimensional control and complex structural features. These characteristics make the products not only beautiful and durable, but also able to meet the strict performance requirements. For example, in aerospace, CNC milled parts are able to withstand extreme temperatures and pressure environments; in medical devices, precision milled components ensure surgical accuracy and safety. In addition, CNC milling enables personalization to meet consumer demand for unique designs and features.

3. Milling Cost Composition and Ways to Reduce Costs

Despite the many advantages of CNC milling, its high cost also discourages many enterprises. The cost mainly comes from several aspects: firstly, the acquisition and maintenance cost of high-precision machine tools; secondly, the research and development and consumption of complex tools; thirdly, the training and salary of professional operators; and fourthly, the procurement of high-quality raw materials. In addition, for small batch or customized production, the programming and debugging time required for each change of machining task is also a cost factor that cannot be ignored.

To reduce the cost of CNC milling, you can start from the following aspects:

Optimize process design: Reduce unnecessary machining steps, improve material utilization and reduce tool wear through reasonable process planning.

Enhance equipment efficiency: Adopt advanced machine tools and tool technology to improve machining speed and accuracy and shorten the production cycle.

Implement automation and intelligence: introduce automated production lines and intelligent monitoring systems to reduce manual intervention and improve production efficiency and quality control.

Scale production: Where possible, apportion fixed costs through scale production to reduce the cost per unit of product.

Training and technology upgrading: Regular skill training for operators to master the latest processing technology and software applications to improve production efficiency and product quality.

Tips:

CNC milling is expensive because it integrates the technological advantages of high precision, high efficiency, high flexibility and high repeatability to produce products with superior characteristics. However, by optimizing process design, improving equipment efficiency, implementing automation and intelligence, large-scale production, and strengthening personnel training and technology upgrades, it is possible to effectively reduce its cost, so that more enterprises can enjoy the manufacturing advantages brought by CNC milling.