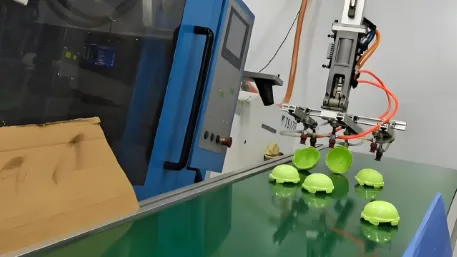

Our Factory – Where Magic Happens

26 Years? That’s Like CNC Royalty!

Dude, walking into their workshop is like entering a precision paradise! Rows of shiny CNC machines humming away – over 100 professional machines, bro!

They serve more than 100 customers annually, and their parts are shipped worldwide. These guys aren’t just manufacturers – they’re part wizards!

Fun fact: Their machining accuracy is ±0.005mm – that’s 10 times finer than a human hair! Can you even imagine that level of precision?

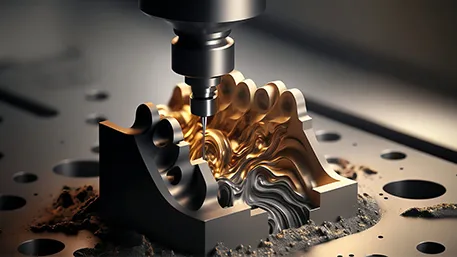

CNC Machining Capabilities – We Don’t Play Around

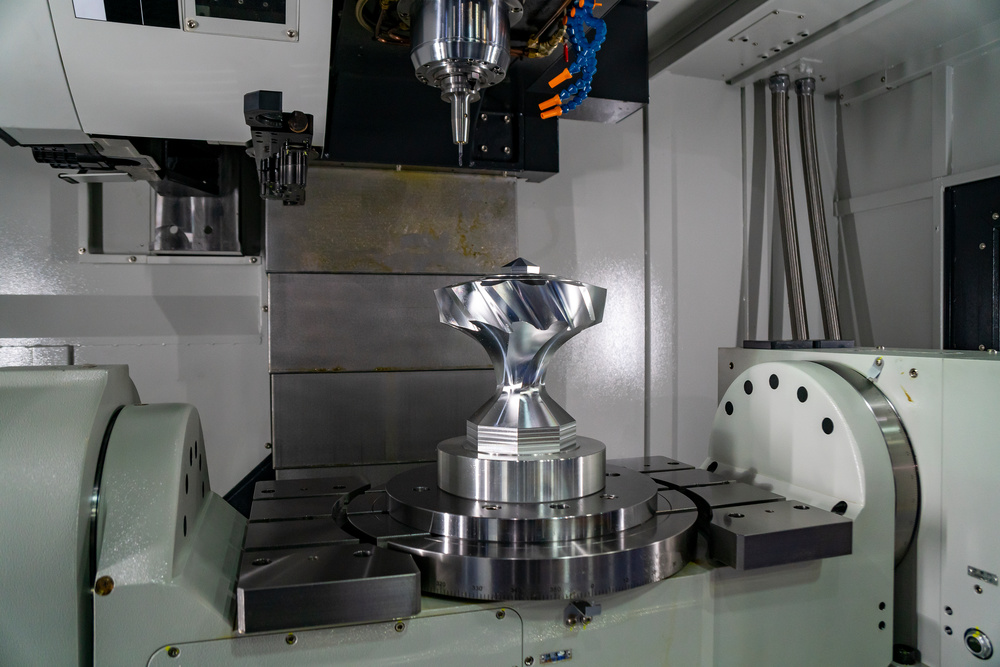

5-Axis Machining? Oh Yeah, We Got That

These guys are rocking advanced 5-axis machining equipment that can make complex parts look easy. We’re talking parts that other shops would run away from!

Main services include:

- CNC Milling: Bro, they can process complex 3D-shaped parts like it’s nothing

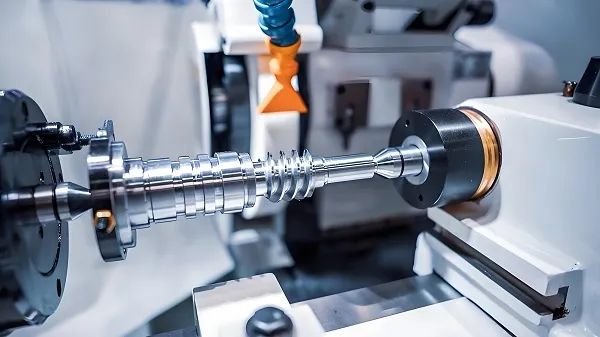

- CNC Turning: Round and cylindrical parts? Done in seconds

- CNC Drilling and Boring: Precision holes that are spot on every time

- CNC Grinding: Surface precision that makes parts look like mirrors

Pro tip: Their ±0.005mm accuracy means your parts will fit together like they were made for each other – because they were!

Materials – We Work With the Good Stuff

Metal Materials – The Tough Guys

Aluminum Alloy

Bro, this stuff is lightweight but strong – perfect when you need parts that don’t weigh a ton but can still take a beating! Great thermal conductivity too.

Common grades: 6061, 7075 – these are the classics!

Stainless Steel

Dude, 304 and 316 stainless? These are the corrosion-resistant kings! Perfect for medical stuff, food equipment, or anything that needs to stay looking fresh.

Pro move: 316 is better for marine or chemical environments – trust me, I’ve used this stuff!

Copper/Brass

These guys have amazing conductivity – perfect for precision parts that need to carry electricity or heat. The finish on brass parts? *Chef’s kiss*

Non-Metal Materials – The Versatile Crew

Engineering Plastics

PEEK, POM, nylon – these plastics are no joke! They can handle heat, wear, and chemicals like champs.

Fun fact: PEEK is used in aerospace – that’s how tough it is!

Rubber Materials

Need parts that can flex and bounce back? Rubber’s your guy. Perfect for seals, gaskets, and anything that needs to absorb shock.

Composite Materials

Carbon fiber composites? Yes please! Strong as steel but lighter than aluminum – ideal for high-performance applications.

Bro, I once held a carbon fiber part – the strength-to-weight ratio is INSANE!

Our Process – We Do Things Right

Design & Engineering

CAD modeling with precise tolerances

Programming

G-code creation for machine instructions

Setup

Fixture setup and tool loading

Machining

Precision cutting with 5-axis capability

Inspection

Quality control with CMM testing

Pro Tip From The Pros

Before any actual cutting, we do a dry run to check for errors. Why? Because we’re not trying to waste expensive materials, bro! This saves time and money in the long run.

Standards & Certifications – We Play By The Rules

Industry Standards We Follow

- ISO 2768: General tolerances for linear and angular dimensions

- ASME Y14.5: GD&T (Geometric Dimensioning and Tolerancing) standards

- ISO 286: ISO system of limits and fits for mating parts

- BS 4656: British standards for surface roughness

- ISO 2859-1: Sampling procedures for inspection by attributes

Fun fact: Our tolerances are often tighter than standard requirements – because we’re perfectionists!

Our Certifications

These aren’t just fancy certificates – they’re proof that we take quality seriously. Every part that leaves our shop has to pass strict inspections.

Test Data – The Proof Is In The Numbers

DISCLAIMER: All test data below is for reference only. Actual results may vary based on specific part requirements and materials.

Accuracy Test Results

| Test Item | Result | Standard |

|---|---|---|

| Linear Positioning Accuracy | ±0.003 mm | ±0.005 mm |

| Repeat Positioning Accuracy | ±0.002 mm | ±0.003 mm |

| X-Y Plane Accuracy | 0.004 mm | 0.005 mm |

| Z-axis Perpendicularity | 0.003 mm | 0.005 mm |

Surface Finish Results

| Material | Ra (μm) | Achievable |

|---|---|---|

| Aluminum 6061 | 0.8 – 1.6 | 0.4 – 0.8 |

| Stainless Steel 304 | 1.6 – 3.2 | 0.8 – 1.6 |

| Brass | 0.8 – 1.6 | 0.4 – 0.8 |

| PEEK | 1.6 – 3.2 | 0.8 – 1.6 |

Performance Stats That Will Impress Your Boss

- CPK ≥ 1.67 for critical dimensions (that’s 6σ quality, bro!)

- On-time delivery rate: 98.5%

- First-pass yield: 95.2%

- Tool life improvement: 25% vs industry average

- Setup time reduction: 30% with quick-change fixtures

Application Fields – We Do It All

Automotive Parts

Engine parts, body components – we make parts that keep cars running smoothly

Mechanical Parts

Core components for all kinds of machinery – reliable and precise

Motorcycle Parts

Custom components that look great and perform even better

Watch Parts

Tiny, intricate parts that show off our true precision skills

Medical Parts

Biocompatible components that meet the strictest medical standards

Aerospace Parts

High-performance parts that can handle extreme conditions

Why Choose Goldcattle? – Let Us Count The Ways

Experience That Matters

26 years in the CNC game, bro! That’s not just experience – that’s wisdom. We’ve seen it all, solved it all, and we keep getting better.

Our team has accumulated technical and management expertise that you just can’t get from a new shop.

Quality That Speaks For Itself

We don’t just meet standards – we exceed them. Every part gets inspected like it’s our own project (because it basically is).

Our quality control system is tight – ISO 9001, SGS, RoHS, CE – we’ve got all the certifications to back up our claims.

Service That Makes You Smile

From your first inquiry to after-sales support, we’re here for you. We don’t just make parts – we build relationships.

Our process is simple: Consultation → Quotation → Sample → Production → Delivery → Support. Easy peasy!

Ready to take your project to the next level?

Let’s Talk About Your Project

We’re here 24/7 to answer your questions and help you create amazing parts

Phone

+86-18150097490

charlie@plasticmetalparts.com

Location

Xiamen, China