In the highly competitive global manufacturing market, high quality injection molds are the key to ensure product accuracy, reduce cost and improve production efficiency. For B2B buyers, choosing a reliable and professional injection mold supplier is crucial. Xiamen Goldcattle injection mold factory, as a leader in the industry, accurately meets the injection mold needs of many B2B buyers by virtue of its exquisite technology, strict quality control system and excellent customer service.

1.Superb technology and equipment

Xiamen Goldcattle Plastic Injection Mold Factory has an experienced and skilled team who are well versed in the design and manufacture of plastic injection molds. The factory is equipped with advanced processing equipment, including high-precision CNC machining centers, EDM machines, wire cutters, precision grinders, etc., to ensure that the mold processing accuracy reaches the micron level. Meanwhile, the team members are proficient in design software such as MOLDFLOW mold flow analysis, UG, PRO-E, AUTOCAD, etc., which can provide customers with one-stop service from product concept design to mold manufacturing.

2.Strict quality control system

Quality is the lifeline of Xiamen Goldcattle injection mold factory. The factory has established a strict quality control system, from raw material procurement, mold design, processing and manufacturing to finished product inspection, each link is strictly controlled. By adopting advanced testing equipment and scientific testing methods, it ensures that each set of molds meets customers’ requirements and industry standards. In addition, the factory also focuses on continuous improvement and innovation, and constantly introduces new technologies and processes to enhance product quality and production efficiency.

3.Customized services to meet diversified needs

B2B buyers’ needs are often diversified and personalized, and Xiamen Goldcattle injection mold factory understands this and provides a full range of customized services. Whether it is home appliances, automobiles, medical devices or other industries’ injection mold needs, the factory can design and manufacture according to customers’ specific requirements. From product structure optimization, material selection to mold structure design, the factory maintains close communication with customers to ensure that the final product meets all their expectations.

3.1 Demand analysis and customer communication

First of all, we will have an in-depth communication with customers to understand their specific needs, including product design drawings, material requirements, dimensional tolerances, production quantities, and the expected production cycle. By fully understanding the customer’s needs, we can more accurately grasp the design direction of the mold and manufacturing standards.

3.2 Mold Design and Development

After clarifying the customer’s requirements, our technical team will start the design and development of the mold. This includes 3D modeling, structural analysis, material selection, cooling system layout and many other aspects. We use advanced CAD/CAM software for design to ensure the accuracy and efficiency of the mold design. At the same time, we also conduct simulation and analysis of the mold to predict possible problems and optimize them in advance, in order to reduce the number of trial molds and shorten the development cycle.

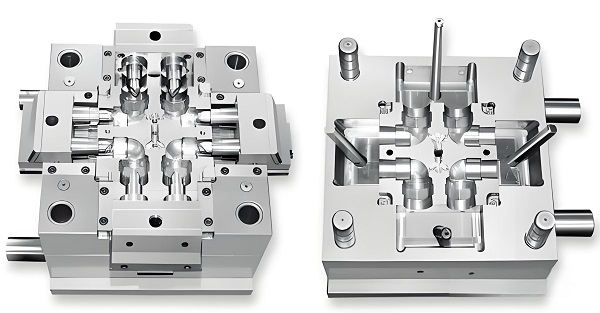

3.3 Mold Manufacturing and Processing

After the completion of mold design and development, we will enter the stage of mold manufacturing and processing. We have advanced processing equipment and exquisite technology, which can ensure the processing precision and surface quality of the mold. During the processing, we will operate in strict accordance with the design drawings and process requirements, and carry out strict quality control for each process. At the same time, we will also carry out heat treatment, polishing and other subsequent processing of the mold to improve the durability and productivity of the mold.

3.4 Trial mold and adjustment

After the mold is manufactured, we will conduct a trial mold to verify the performance and reliability of the mold. During the mold trial, we will pay close attention to the molding quality of the product, dimensional accuracy and the operation status of the mold. Once problems are found, we will analyze and adjust them in time to ensure that the molds can meet the customer’s production requirements.

4.Efficient production and delivery capability

In modern manufacturing industry, time is money, Xiamen Goldcattle injection mold factory understands the importance of efficient production, so we constantly optimize the production process and improve the production efficiency. The factory adopts advanced production management system, real-time monitoring and scheduling of production progress, to ensure that the mold production can be completed on time and in quality. At the same time, the factory also has a perfect logistics system, which can quickly respond to the customer’s delivery needs, and deliver the molds to customers on time.

5.Excellent Customer Service

Customer satisfaction is the eternal pursuit of Xiamen Goldcattle injection mold factory. The factory has established a perfect customer service system, from pre-sales consultation, program design to after-sales support, to provide customers with a full range of services. No matter what kind of problems or demands customers encounter, the factory can respond quickly and provide effective solutions. In addition, the factory also focuses on long-term cooperation and win-win development with customers, and wins customers’ trust and loyalty by providing high-quality products and services.

Injection Mold Customized FAQ

1. What are the main types of customized plastic injection molds that Xiamen Goldcattle Plastic Injection Mold Factory provides?

A: Xiamen Goldcattle Injection Mould Factory focuses on providing high-quality customized injection mold services for various industries, including but not limited to automotive parts, home appliances, electronic products, medical devices, daily necessities and other fields of injection mold design and manufacturing. We have rich experience and technical strength to meet the diversified mold customization needs of our customers.

2. What is the process of customized injection mold?

A: The process of customized injection molds includes the following steps: firstly, the customer puts forward the demand for customized molds, including product drawings, material requirements, dimensional tolerances, etc.; secondly, our technical team will have an in-depth communication with the customer to clarify the mold design scheme and details; then, according to the design scheme, we will carry out the design and manufacture of the molds, including the 3D modeling, mold machining, heat treatment, polishing, etc.; finally, we will carry out the mold trial and acceptance. Then, we carry out mold design and manufacturing according to the design plan, including 3D modeling, mold processing, heat treatment, polishing and other processes; finally, we carry out mold trial and acceptance to ensure that the mold meets the customer’s production requirements.

3. How to ensure the precision and quality of injection molds?

A: Xiamen Goldcattle injection mold factory takes many measures to ensure the precision and quality of the molds. We have advanced processing equipment and testing instruments to ensure the precision and stability of mold processing. Meanwhile, we have established a strict quality control system, from raw material procurement, mold design, processing and manufacturing to finished product inspection, every step is strictly controlled. In addition, our technical team has rich experience and professional knowledge, which can find and solve the problems in the process of mold manufacturing in time to ensure that the quality of the mold meets the customer’s requirements.

4. How long is the cycle time for mold customization?

A: The cycle time of mold customization varies depending on factors such as product complexity, production quantity and customer demand. Generally speaking, the customized cycle time for small and medium-sized injection moulds is between a few weeks to one month. For large or complex molds, the customization cycle may be longer. We will make a detailed production plan and try to shorten the customization cycle according to the customer’s specific needs and situation in order to meet the customer’s production needs.