As a leading CNC turned parts manufacturer in China, Xiamen Goldcattle has been delivering high-precision machining solutions for over 26 years. Specializing in custom metal and plastic components, our factory combines advanced technology, experienced engineering teams, and a customer-centric approach to meet diverse industrial needs worldwide.

1. Uncompromising Precision in CNC Turning Services

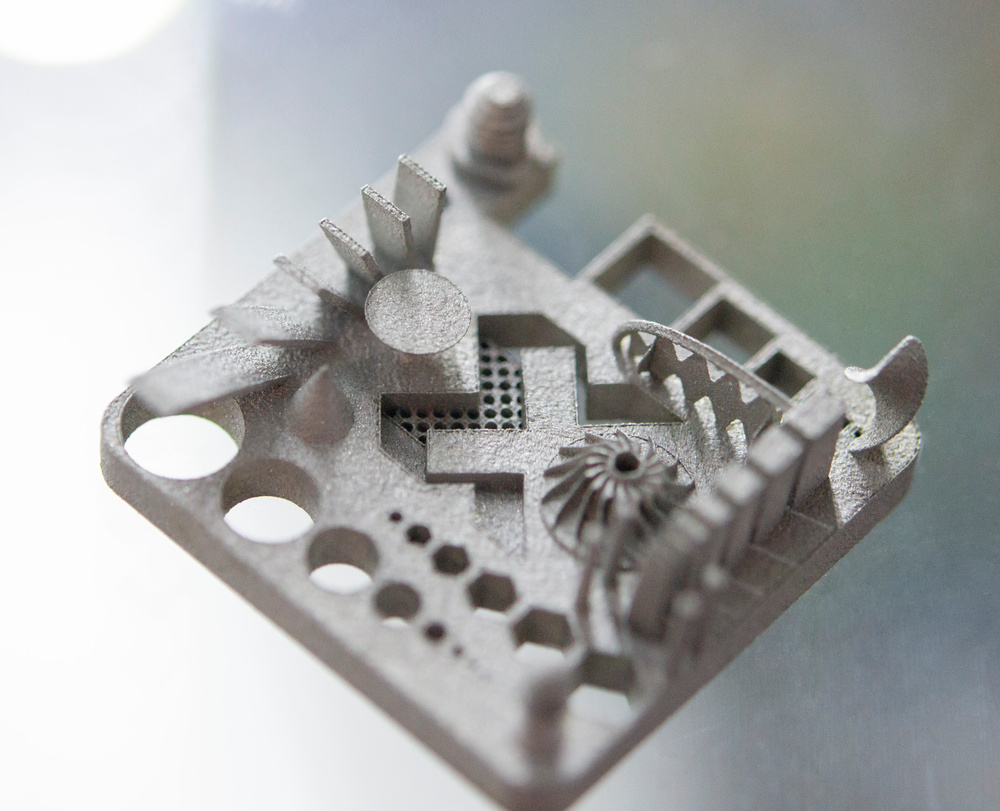

At the core of our expertise lies CNC turning, a cornerstone of our comprehensive machining capabilities. We leverage state-of-the-art 5-axis processing equipment to achieve tolerances as tight as ±0.005mm, ensuring every turned part meets the most rigorous standards. Our services include:

- Precision Turning: For cylindrical components in materials like aluminum, brass, stainless steel, copper, and bronze.

- Multi-Axis Machining: Complex geometries and multi-step operations for aerospace, automotive, and medical applications.

- Hardened Material Processing: Expertise in machining high-strength alloys and heat-treated metals without compromising accuracy.

Whether you need simple shafts or intricate aerospace components, our CNC turning solutions guarantee consistency, surface finish, and dimensional accuracy.

2. Comprehensive Capabilities Beyond Turning

As a full-service manufacturer, we offer end-to-end solutions for custom parts:

- Diverse Machining Services: Milling, drilling, boring, threading, EDM (electrical discharge machining), and rapid prototyping.

- Material Versatility: Processable materials include non-ferrous metals, plastics, and advanced alloys, with options for anodizing, plating, and other surface treatments.

- Multi-Industry Applications:

- Automotive: Custom engine components, bearings, and transmission parts.

- Aerospace: High-precision aluminum alloy die-castings and structural components.

- Medical Devices: Smooth-surface implants and surgical instrument parts.

- Consumer Electronics: Miniaturized components for watches, electronics, and hardware.

3. Why Choose Goldcattle as Your CNC Partner?

Technical Excellence

- 26 Years of Experience: A proven track record in mold design, CNC programming, and mass production.

- 100+ Processing Equipment: Advanced machinery to handle low-volume prototyping and high-volume production.

- In-House Expertise: A team of industrial designers and engineers skilled in optimizing part design for manufacturability.

Quality Assurance

- International Certifications: ISO 9001, SGS, CE, and RoHS compliance ensure adherence to global quality standards.

- Rigorous Inspection: Professional quality control equipment guarantees every part meets customer specifications.

Customer-Centric Solutions

- OEM/ODM Services: Full customization based on drawings, samples, or conceptual designs.

- Fast Turnaround: Rapid prototyping (72-hour lead times) and efficient production scheduling.

- Global Partnerships: Serving 98+ international clients with transparent communication and competitive pricing.

4. Innovation and Sustainability

As a national high-tech enterprise, we prioritize innovation and sustainable practices:

- Eco-Friendly Processes: Compliance with RoHS standards for environmentally responsible manufacturing.

- Continuous Improvement: Regular equipment upgrades and R&D investments to stay ahead of industry trends.

Partner with Goldcattle for Your Next Project

Whether you need a single prototype or large-scale production, Xiamen Goldcattle is your reliable partner for CNC turned parts and beyond. Our commitment to precision, efficiency, and customer satisfaction has made us a trusted name in global manufacturing.

Contact us today to discuss your requirements and discover how our expertise can elevate your next project.