Precision Engineered for Global Markets

At Xiamen Goldcattle Plastic & Metal Products Co., Ltd., we specialize in transforming ideas into high-performance, precision-engineered plastic components. Since our establishment in 2014, we have grown into a certified manufacturer dedicated to serving a global clientele across North America, Northern Europe, and beyond. With a foundation built on the principles of “Quality, Efficiency, Integrity, and Service,” we deliver complete solutions from initial design to final assembly, ensuring every part meets the highest standards of excellence and reliability.

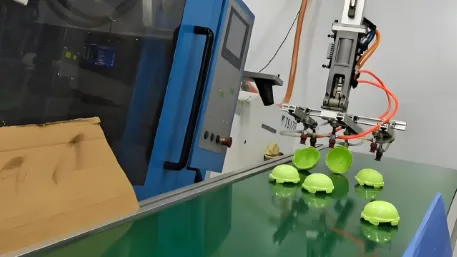

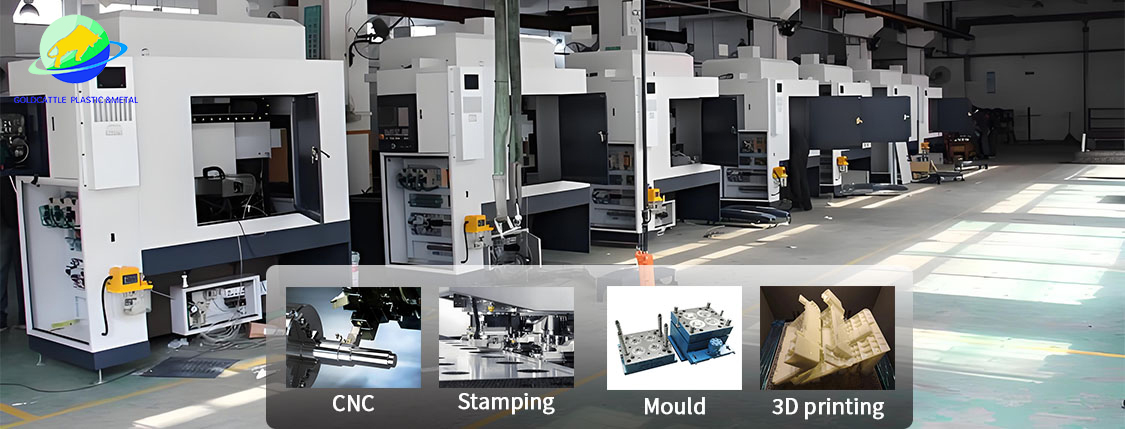

Our Modern Manufacturing Facility

Our state-of-the-art manufacturing facility is equipped with advanced injection molding machines and maintains a clean production environment to ensure the highest quality standards. We operate as a national grade high-tech enterprise with 26 years of experience in the industry.

Our Core Manufacturing Capabilities

We provide a comprehensive suite of services to cover every stage of your product development, from prototyping to mass production.

1. Advanced Injection Molding

As a core competency, our injection molding service is designed for high-volume production of detailed and complex parts. We excel in thin-wall injection molding, a process ideal for creating lightweight, robust components for packaging, automotive, and consumer electronics with high dimensional accuracy. Furthermore, our expertise extends to specialized processes like microcellular foam (MuCell) molding, which reduces part weight and minimizes warping and sink marks for superior quality.

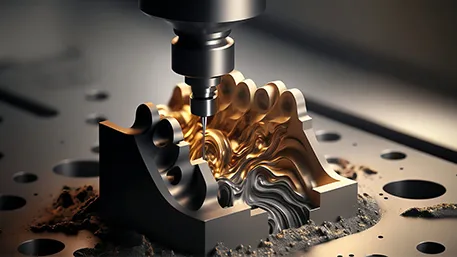

2. Precision CNC Machining

For prototypes, low-volume batches, or parts requiring extremely tight tolerances, our CNC machining (milling and turning) offers unmatched flexibility. This process is perfect for complex geometries and a wide range of engineering plastics, providing exceptional accuracy and surface finish. Our 5-axis processing equipment achieves an accuracy of ±0.005mm.

3. Comprehensive Secondary & Finishing Services

Our service doesn’t end with molding or machining. We offer a full range of secondary operations to deliver ready-to-use components:

- Overmolding: Combining materials to create soft-grip surfaces or multi-material components

- Surface Finishing: Including texture application (e.g., Mold-Tech), painting, silk-screen printing, and laser engraving

- Assembly & Integration: Full component assembly, including the installation of threaded inserts and other hardware

Table 1: Our Core Capabilities at a Glance

|

Capability

|

Key Process

|

Best For

|

Tolerance Range

|

|

High-Volume Production

|

Injection Molding (incl. Thin-Wall)

|

Complex, detailed parts in large quantities

|

+/- 0.05 – 0.1mm

|

|

Prototyping & Complex Parts

|

CNC Machining (Milling & Turning)

|

Low-volume batches and complex geometries

|

+/- 0.001 – 0.1mm

|

|

Lightweighting & Structural

|

Microcellular (MuCell) Foam Molding

|

Reducing weight & improving dimensional stability

|

Subject to design

|

|

Value-Added Finishing

|

Overmolding, Painting, Assembly

|

Enhancing function, aesthetics, and readiness

|

N/A

|

Material Selection Expertise

Choosing the right material is critical to a part’s performance. Our engineering team guides you through our extensive selection of thermoplastics to find the optimal balance of properties, cost, and manufacturability.

Table 2: Common Material Selection Guide

|

Material

|

Key Properties

|

Typical Applications

|

|

ABS

|

High impact strength, good stiffness, excellent surface finish

|

Automotive interiors, consumer electronics housings, toys

|

|

Polypropylene (PP)

|

Excellent chemical resistance, fatigue resistance, low cost

|

Living hinges, food containers, automotive components

|

|

Polycarbonate (PC)

|

High impact strength, transparency, good heat resistance

|

Protective covers, lenses, transparent assemblies

|

|

Nylon (PA6, PA66)

|

High strength, good wear resistance, and toughness

|

Gears, bearings, and mechanical components

|

|

Acetal (POM)

|

Low friction, high stiffness, excellent dimensional stability

|

Precision gears, sliders, and fasteners

|

|

Polyethylene (HDPE/LDPE)

|

Good chemical resistance, moisture barrier, and flexibility

|

Bottles, chemical tanks, and packaging

|

Industries We Serve

Our parts are integral to the success of products in demanding industries worldwide:

Automotive & Transportation

Interior trim, functional components, under-hood parts, and lightweight structural elements.

Consumer Electronics

Durable and aesthetically pleasing housings, connectors, and internal components for devices.

Home Appliance & Hardware

Reliable parts for white goods, power tools, plumbing fixtures, and furniture.

Medical & Laboratory

Components for diagnostic devices, housings, and disposable items, with attention to material compliance and precision.

The Goldcattle Advantage: Quality & Partnership

Certified Quality System

We operate under an ISO 9001:2000 certified quality management system. Our in-house quality team performs inspections throughout production, from raw material checks to final dimensional verification using tools like CMM, ensuring every shipment meets your specifications.

Engineer-to-Engineer Support

Our team of experienced engineers provides Design for Manufacturability (DFM) feedback early in your design phase. We help optimize part design, material selection, and mold design to prevent issues like warping or sink marks, ensuring a smooth transition to production and cost-effectiveness.

Reliable Global Logistics

With extensive experience in international trade, we offer flexible shipping terms (FOB, CIF, EXW, etc.) and ensure timely delivery. Our average lead time is 15 days, helping you maintain efficient supply chain operations.

Our Process Flow

- Design Consultation & DFM – Initial design review and manufacturability analysis

- Quotation & Mold Design – Detailed pricing and mold engineering

- Tooling & Sample Approval – Mold fabrication and sample validation

- Mass Production & QC – Volume manufacturing with strict quality control

- Delivery & Support – Timely shipping and ongoing customer support

Let’s Start Your Project

Whether you are designing a new product or seeking a more reliable manufacturing partner, Xiamen Goldcattle has the expertise, technology, and commitment to support your goals.

Contact us today to discuss your custom plastic part requirements and receive a detailed project analysis.

Company Information

Xiamen Goldcattle Plastic & Metal Products Co., Ltd.

- Plant Area: 5,000-10,000 square meters

- Key Certifications: ISO 9001:2000

- Experience: 26 years in precision manufacturing

- Export Markets: North America, Northern Europe, and beyond

- Production Capacity: 1,000,000 pieces per month

Contact Information

- Location: Xiamen, Fujian, China

“High-quality, efficiency, honesty and service” – Our guiding principles for sustainable operation and customer satisfaction.