Imagine a world where every component—from the tiniest medical implant to the most complex aerospace engine part—functions flawlessly, with no room for error. That’s the reality zero tolerance machining products deliver. These engineering marvels, crafted to near-perfect specifications, are the backbone of industries where precision isn’t just a goal—it’s a lifeline. At GoldCattle, we’ve mastered the art and science of zero tolerance machining, blending cutting-edge technology with decades of expertise to redefine what’s possible.

Understanding Zero Tolerance Machining: Beyond Precision

Zero tolerance machining refers to manufacturing components with dimensional accuracy so tight that deviations are measured in microns or even nanometers. While achieving absolute zero variation is theoretically impossible due to material limitations and environmental factors, modern CNC (Computer Numerical Control) systems and advanced metrology allow us to push tolerances to ±0.0005mm (±0.00002 inches)—a level where a human hair’s thickness (≈0.06mm) would dwarf the allowable error .

This extreme precision is governed by standards like ASME Y14.5, which defines geometric dimensioning and tolerancing (GD&T). For example, a position tolerance with a material condition modifier allows zero tolerance under specific conditions, ensuring parts fit seamlessly in high-stress environments .

The Machinery and Materials Behind Zero Tolerance

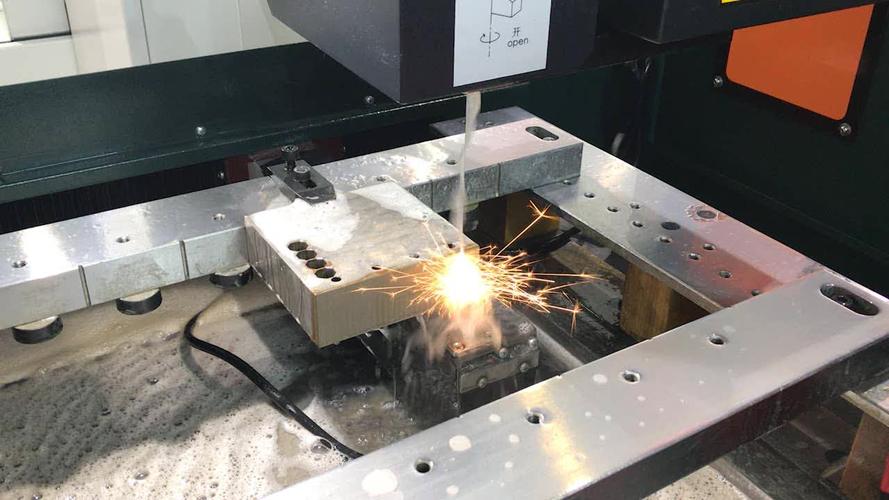

1. State-of-the-Art Equipment

GoldCattle’s facility houses 5-axis CNC machining centers capable of dynamic motion across three linear axes (X, Y, Z) and two rotational axes (A, C). These machines can carve intricate geometries with ±0.0005mm repeatability, outperforming traditional 3-axis systems by 50% in precision . For instance, a 5-axis machine can mill a turbine blade’s aerodynamic curves in a single setup, eliminating errors from repositioning—a process that would require 3–4 setups on older machines.

2. Material Selection for Extreme Performance

- Titanium Alloys: Used in medical implants and aerospace components for their strength-to-weight ratio and biocompatibility. Grade 5 Ti-6Al-4V, for example, withstands 800MPa tensile stress while resisting corrosion .

- Metal Ceramics (Ti(C,N)): Ultra-hard materials with 92.5 HRA hardness and 2.0–2.1 GPa strength, ideal for cutting tools and high-wear industrial parts .

- Engineering Plastics: PEEK (Polyether Ether Ketone) offers chemical resistance and thermal stability, making it critical for semiconductor wafer carriers.

3. The Zero Tolerance Workflow

- Design Validation: CAD/CAM software simulates stress points and tolerances, ensuring designs meet ISO 2768-1 and ASME Y14.5 standards.

- CNC Machining: High-speed spindles (up to 40,000 RPM) and diamond-coated tools remove material with sub-micron precision. For example, machining a medical syringe plunger requires surface finishes smoother than 0.1μm Ra to prevent drug contamination .

- Metrology & Inspection: Coordinate Measuring Machines (CMM) with 0.001mm resolution verify dimensions, while 3D laser scanning maps surface topography. A single aerospace bracket might undergo 100% inspection across 500+ points .

- Surface Treatment: Processes like electropolishing reduce friction in medical devices, while anodizing enhances corrosion resistance in automotive parts.

Applications in High-Stakes Industries

1. Medical Devices

- Implants: Custom knee replacements require ±0.002mm tolerance to mimic natural joint motion, reducing long-term wear .

- Surgical Tools: Laser-cut scalpels with 0.01mm edge sharpness ensure precise incisions, minimizing trauma .

2. Aerospace & Defense

- Turbine Blades: Nickel-based superalloys machined to ±0.005mm tolerance withstand 1,200°C temperatures in jet engines .

- Avionics: Micro connectors with 20μm pitch enable reliable data transmission in fighter jets .

3. Semiconductor Manufacturing

- Wafer Chucks: Diamond-turned aluminum components with ±0.001mm flatness hold silicon wafers during lithography, ensuring nanometer-scale circuit patterns .

4. High-Precision Robotics

- Actuator Gears: Micro-machined gears with ±0.001mm backlash enable robotic arms to assemble electronics with sub-millimeter accuracy .

Why GoldCattle Leads in Zero Tolerance Machining

1. Decades of Expertise

With 26 years of experience, we’ve delivered critical components for NASA satellites, medical device leaders, and Formula 1 teams. Our engineers specialize in DFM (Design for Manufacturability), optimizing designs to balance cost and precision.

2. Advanced Technology

Our 5-axis CNC machines and EDM (Electrical Discharge Machining) systems handle materials as hard as tungsten carbide, achieving aspect ratios of 38:1 for micro-structures .

3. Rigorous Quality Assurance

Every part undergoes FAI (First Article Inspection) and PPAP (Production Part Approval Process), ensuring compliance with AS9100D (aerospace) and ISO 13485 (medical) standards .

4. Custom Solutions

From prototype to mass production, we offer turnkey services—including mold design and assembly. A recent project for a drone manufacturer reduced lead time by 40% via integrated 5-axis machining and in-house finishing .

FAQs About Zero Tolerance Machining

Q: What’s the smallest feature size you can machine?

A: We regularly produce features as small as 40 microns (0.04mm), suitable for microfluidic channels and fiber optic connectors .

A: We regularly produce features as small as 40 microns (0.04mm), suitable for microfluidic channels and fiber optic connectors .

Q: How does zero tolerance machining differ from standard precision machining?

A: While standard precision aims for ±0.05mm, zero tolerance targets ±0.001mm or tighter, requiring advanced metrology and specialized tooling .

A: While standard precision aims for ±0.05mm, zero tolerance targets ±0.001mm or tighter, requiring advanced metrology and specialized tooling .

Q: Can you machine non-metal materials?

A: Yes! We work with ceramics, PEEK, and composites. For example, a ceramic valve seat for a semiconductor pump must maintain ±0.003mm flatness to prevent gas leaks .

A: Yes! We work with ceramics, PEEK, and composites. For example, a ceramic valve seat for a semiconductor pump must maintain ±0.003mm flatness to prevent gas leaks .

Q: What industries benefit most from zero tolerance products?

A: Aerospace, medical, and semiconductor sectors, where failures can lead to catastrophic consequences or multimillion-dollar losses .

A: Aerospace, medical, and semiconductor sectors, where failures can lead to catastrophic consequences or multimillion-dollar losses .

Q: How do you handle thermal expansion in high-temperature applications?

A: We simulate thermal cycling in CAD models and use materials like Invar (36Ni-Fe) with 0.8ppm/°C thermal expansion to minimize dimensional shifts .

A: We simulate thermal cycling in CAD models and use materials like Invar (36Ni-Fe) with 0.8ppm/°C thermal expansion to minimize dimensional shifts .

Ready to Engineer Perfection?

Zero tolerance machining isn’t just about precision—it’s about enabling innovation. At GoldCattle, we combine cutting-edge technology with relentless attention to detail to deliver components that redefine industry standards.

Contact us today at https://www.xmgoldcattle.com/ to discuss your project. Whether you need a single prototype or 10,000 production parts, we’ll ensure every dimension is flawless.