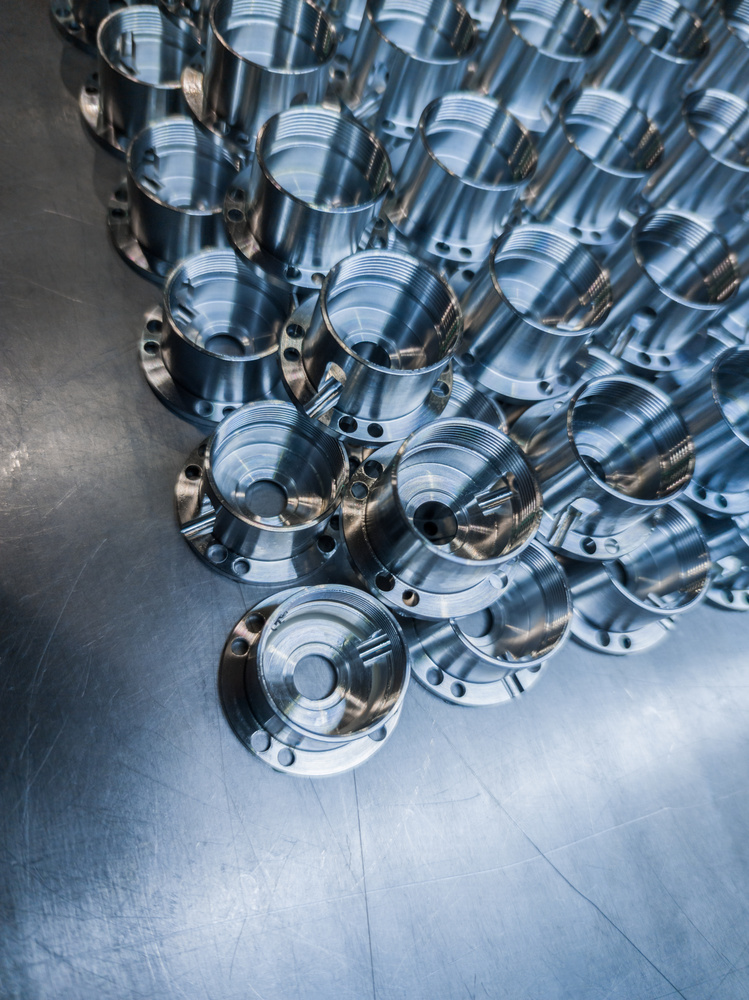

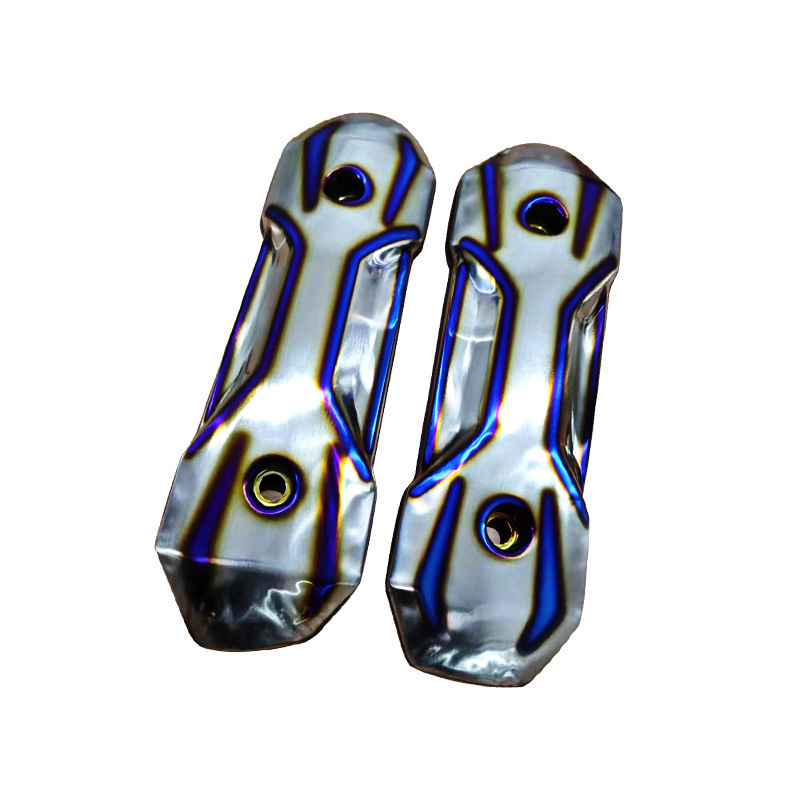

As a professional CNC machining custom manufacturer, Xiamen Goldcattle possesses advanced CNC custom machining equipment and has extensive experience in CNC milling stainless steel parts, providing precision stainless steel parts to numerous partners worldwide.

Introduction: Is Stainless Steel CNC Milling Important?

When processing CNC stainless steel parts, without professional operators and equipment, it is difficult to produce precision stainless steel parts, which not only increases production costs but also significantly delays delivery deadlines.

The main difficulties in stainless steel processing are reflected in three aspects:

- The influence of cutting resistance

- Work hardening during processing, leading to accelerated tool wear

- Poor thermal conductivity, materials are prone to temperature exceeding limits, affecting the final precision and quality of parts

Choosing a professional CNC milling service provider is not just about finding a processing partner, but also a key investment in ensuring project success. Professional service providers have the knowledge, equipment, and process experience to effectively solve these technical challenges and provide you with high-quality, high-precision stainless steel parts.

CNC Milling Stainless Steel Parts Processing Requirements

Only with advanced equipment and rich processing experience can the qualification rate and precision of stainless steel parts be maximized:

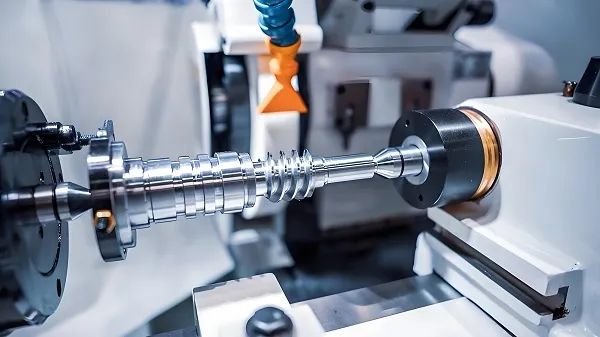

Multi-axis Machining Capability: Utilizing 5-axis CNC machining centers, complex geometric shapes can be completed in a single setup, greatly reducing repeat positioning errors. This is particularly important for stainless steel thin-walled parts, effectively avoiding deformation risks caused by multiple setups.

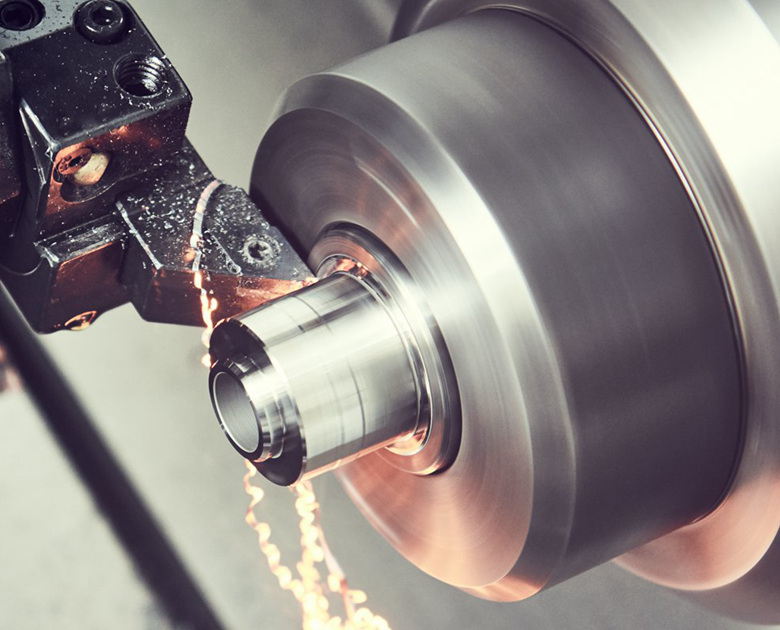

High-pressure Cooling Systems: Equipped with high-pressure cooling systems above 3000 psi, which can effectively reduce cutting zone temperatures, promptly flush away chips, and prevent the formation of tool built-up edges. This not only extends tool life but also significantly improves part surface quality.

High Rigidity Machine Structure: Machine beds are made of high-rigidity cast iron materials, combined with precision guideways and ball screws, which can effectively suppress vibrations in stainless steel processing. High rigidity is the foundation for ensuring processing accuracy and surface finish, ensuring stable processing performance even under heavy cutting conditions.

Material Science and Tool Technology Expertise

In-depth material understanding and professional tool technology are key to overcoming stainless steel processing challenges:

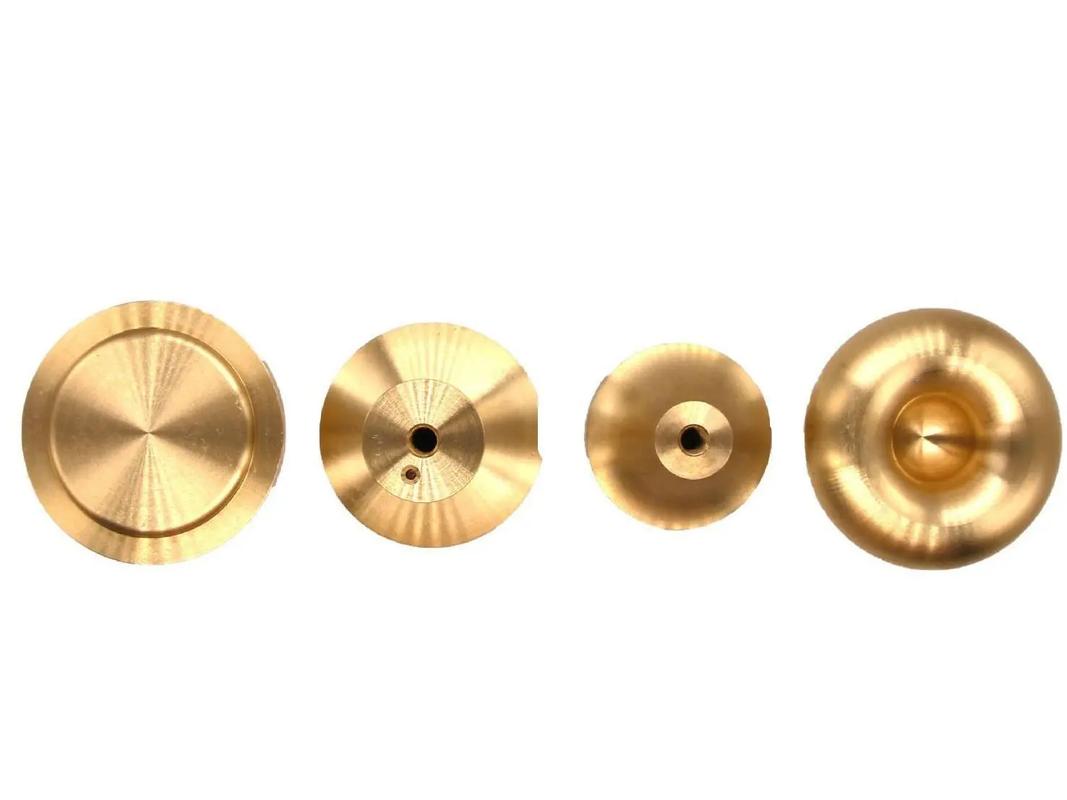

Stainless Steel Material Property Analysis: Developing personalized processing solutions based on the processing characteristics of different stainless steel grades. 304 stainless steel has good corrosion resistance and processability, suitable for general purposes; 316 stainless steel contains molybdenum, offering superior corrosion resistance but slightly higher processing difficulty; 17-4PH precipitation-hardening stainless steel can achieve high strength through heat treatment, requiring special attention to processing parameter control.

Professional Tool Selection: According to the processing characteristics of different stainless steels, specialized coated carbide tools are selected. For example, when processing 316 stainless steel, carbide tools with higher cobalt content combined with AlTiN coating are used; for high-strength stainless steels like 17-4PH, ultra-fine grain carbide tools are employed. At the same time, precise optimization of cutting speed, feed rate, and cutting depth ensures processing efficiency while maximizing tool life.

Core Application Areas: Your Industry, Our Solutions

Medical Devices and Biocompatibility Requirements

Medical equipment parts have extremely high requirements for materials and processing quality:

Medical-grade Stainless Steel Processing: Specialized processing of 316L VL, 17-4PH and other medical-grade stainless steels, ensuring material purity and biocompatibility. These materials are widely used in implantable devices, surgical tools, and medical equipment components.

Precision Processing Capability: Achieving mirror-level surface finish (Ra < 0.4μm), effectively preventing bacterial growth and biological contamination. Simultaneously, micron-level tolerances (±0.005mm) can be achieved to meet precision assembly requirements.

Compliant Post-processing: Providing surface treatment services such as electropolishing and passivation that meet biocompatibility requirements. These processes not only improve surface finish but also enhance material corrosion resistance, ensuring the safety and reliability of medical devices during long-term use.

Aerospace and High-strength Structural Components

The aerospace industry has strict requirements for part strength, reliability, and weight:

High-strength Material Processing: Specialized processing of 15-5PH, 17-4PH and other high-strength precipitation-hardening stainless steels, which have excellent strength-to-weight ratios and corrosion resistance, widely used in aerospace structural components.

Structural Integrity Assurance: Focusing on part structural integrity and fatigue strength, using advanced processing technologies and testing techniques to ensure part reliability under extreme working conditions.

Strict Quality System: Strictly following AS9100 aerospace quality management system, with rigorous quality control and traceability at every stage from material procurement to finished product delivery.

Complex Feature Processing Capability: Possessing the ability to process deep cavities, complex curved surfaces, thin-walled structures and other features, meeting the complex design requirements of aerospace parts.

Food Industry and Corrosion Resistance Hygiene Standards

Food processing equipment has special requirements for hygiene and corrosion resistance:

Hygienic Design Processing: Ensuring parts are designed without dead corners and easy to clean, meeting food-grade hygiene standards. Surface treatment uses mechanical polishing and passivation to form a uniform chromium oxide protective film.

Corrosion Resistance Treatment: Through professional passivation treatment processes, significantly improving the corrosion resistance of stainless steel surfaces, enabling them to withstand frequent chemical cleaning and high-temperature, high-pressure environments. This is crucial for the long-term use of food processing equipment.

Design Optimization Guide: Manufacturing-oriented Design Recommendations

Design optimization is an important way to reduce costs and improve quality:

Internal Corner Radius Design: It is recommended that the internal corner radius be slightly larger than the radius of the end mill used (usually 0.1mm or more), avoiding sharp tool turns during processing. This not only extends tool life but also improves surface quality and reduces stress concentration.

Uniform Wall Thickness Design: Design uniform wall thickness as much as possible to avoid thermal stress and deformation caused by uneven heat dissipation. For necessary wall thickness changes, gradual transitions should be used to reduce stress concentration points.

Thin-wall Design Specifications: For stainless steel materials, the minimum wall thickness is recommended to be no less than 0.8mm. For large-area thin-wall structures, it is recommended to add stiffeners or adopt other structural optimization measures to improve part rigidity and reduce deformation risks during processing and use.

Deep Hole/Cavity Processing Considerations: When the depth-to-diameter ratio exceeds 10:1, processing difficulty increases significantly. It is recommended to communicate with manufacturing engineers to consider alternative solutions such as through holes, segmented processing, etc., to reduce processing costs and improve processing quality.

Thread Design Optimization: Blind hole threads should reserve at least 1.5 times the thread pitch of retraction space at the bottom to ensure thread quality and prevent tool breakage. At the same time, standard thread sizes and tolerances are recommended to reduce processing complexity and costs.

Quality Assurance: Full Process Control from Drawing to Qualified Parts

Comprehensive Inspection System

Establishing a comprehensive quality inspection system to ensure every part meets design requirements:

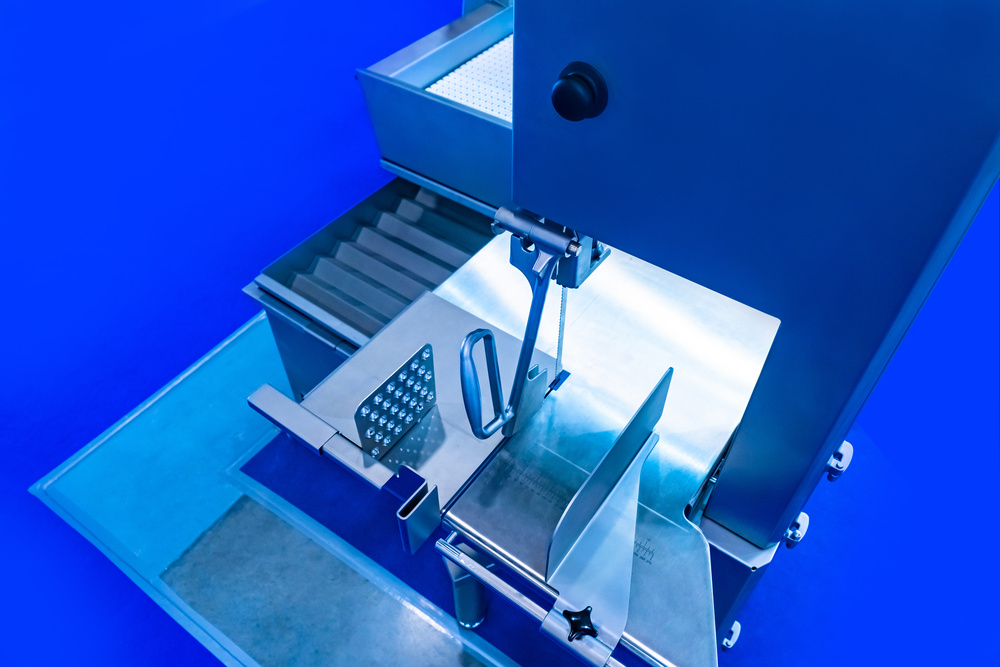

First Article Inspection: Using high-precision coordinate measuring machines (CMM) for full-size verification of first articles, generating detailed inspection reports for archiving. First article inspection data is traceable, providing a reliable basis for subsequent mass production.

In-process Inspection: In mass production processes, statistical process control (SPC) methods are used to regularly sample key dimensions and characteristics. By real-time monitoring of the processing process, deviations are detected and corrected in a timely manner, ensuring process stability.

Final Inspection Confirmation: Using precision testing equipment such as optical comparators, profilometers, and surface roughness testers for final confirmation of finished products. All inspection data is recorded and archived to ensure product quality traceability.

Certifications and Standards

Obtaining multiple industry certifications, demonstrating professional capabilities and quality levels:

Quality Management System Certification: Holding ISO 9001:2015 quality management system certification, ensuring overall management level meets international standards.

Industry-specific Certifications: According to the industry sectors served, obtaining corresponding specialized certifications, including IATF 16949 (automotive industry), AS9100D (aerospace), ISO 13485 (medical devices), etc. These certifications demonstrate professional capabilities and compliance in specific industries.

Frequently Asked Questions

Q: What typical tolerances can be achieved with CNC milled stainless steel parts?

A: Standard tolerances can reach ±0.025mm, and under high-precision processing conditions, tight tolerances of ±0.005mm can be achieved. Specific tolerance capabilities depend on part features, size, and material characteristics. Our engineers will provide the most economically feasible tolerance solutions based on your specific requirements.

Q: What types of stainless steel do you typically process?

A: We specialize in processing various types of stainless steel, the most common including:

- Austenitic stainless steel: 304, 316, 316L, 321, etc.

- Martensitic stainless steel: 416, 420, 440C, etc.

- Precipitation-hardening stainless steel: 17-4PH, 15-5PH, 17-7PH, etc.

- Duplex stainless steel: 2205, 2507, etc.

Our material experts can recommend the most suitable stainless steel material based on your corrosion resistance requirements, strength needs, and budget considerations.

Q: What is the typical lead time from quote to delivery?

A: We provide fast response services:

- Quotes for simple parts are usually provided within 1-2 working days

- For complex parts or projects requiring special processes, quotation time may extend to 3-5 working days

- Production lead time depends on part complexity, quantity, and current capacity, typically 5-15 working days

- We offer expedited service options, completing urgent orders within 3-7 working days

Q: How can I optimize my design to reduce CNC milling costs?

A: In addition to referring to the DFM suggestions above, you can also consider the following optimization measures:

- Simplify part geometry and reduce complex features

- Avoid hard-to-process features such as deep cavities and deep holes

- Choose standard tool sizes corresponding to fillet radii and hole diameters

- Appropriately relax tolerance requirements for non-critical features

- Consider modular design of parts for easier processing and assembly

We provide free DFM analysis services to help you optimize part manufacturability during the design phase and reduce production costs.

How to Obtain High-quality Stainless Steel Parts?

Professional CNC milling stainless steel parts service is not just a reflection of processing capabilities, but a comprehensive demonstration of technical strength, quality control, and industry experience. We have advanced equipment, professional technical teams, and complete quality systems, enabling us to provide one-stop solutions from design optimization to finished product delivery.

Whether you are in the medical device, aerospace, or food industry, we can provide customized processing services according to your specific needs. Our advantages include:

- Advanced processing equipment and process technology, ensuring high-precision, high-quality processing results

- In-depth material understanding and professional tool technology, effectively solving stainless steel processing challenges

- Rich industry experience, familiar with special requirements and standards of various industries

- Complete quality control system, ensuring product quality stability and reliability

- Fast response service capabilities to meet your urgent needs

Contact us now to get free DFM analysis and project evaluation. Let our professional team provide the best processing solutions for your project and jointly ensure successful project implementation.

Take Action Now:

- Send your part drawings and requirement specifications

- Our engineers will provide preliminary evaluation within 24 hours

- Get detailed quotation and delivery information

- Start your project and enjoy professional processing services

Professional CNC milling stainless steel parts service starts here.