In today’s fast-paced technological era, every electronic device and industrial instrument requires a robust yet precise “home” — the metal housing. More than just a protective barrier, it symbolizes quality and technological advancement. Xiamen Goldcattle Industrial & Trade Co., Ltd., a national high-tech enterprise with 26 years of professional experience, is crafting perfect product enclosures for global clients through its outstanding custom CNC metal housing machining services.

Chapter 1: The Importance of Metal Housings — More Than Just Protection

Metal housings play a crucial role in modern manufacturing. They must not only shield internal precision electronic components from external environmental factors but also offer excellent heat dissipation, electromagnetic shielding, and meet multiple requirements such as aesthetics, portability, and durability. In high-end fields like aerospace, medical devices, automotive manufacturing, and communication equipment, the precision and quality demands for metal housings reach the micron level.

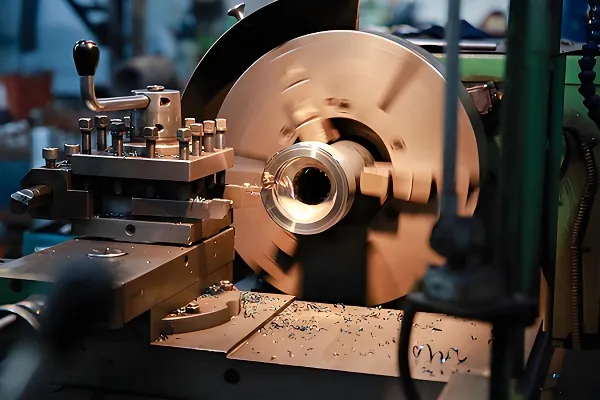

Traditional casting and sheet metal processes often struggle to meet complex structural and high-precision requirements. The emergence of CNC machining technology has revolutionized metal housing manufacturing. Equipped with computer-controlled precision machining equipment, we can achieve a machining accuracy of ±0.005mm — equivalent to 1/20 the diameter of a human hair — providing a solid foundation for product reliability and stability.

Chapter 2: Diverse Housing Solutions — Meeting Industry-Specific Needs

Xiamen Goldcattle’s custom CNC metal housing machining services cover multiple fields, catering to the unique needs of different industries:

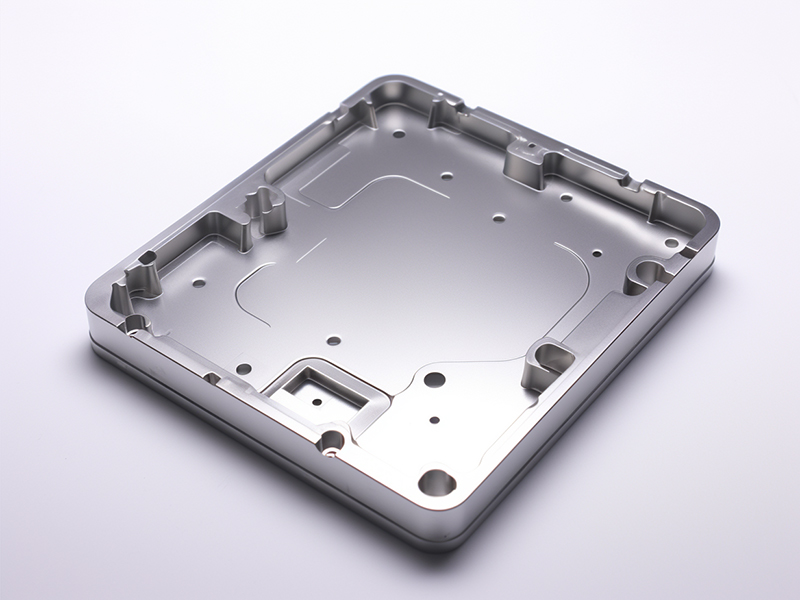

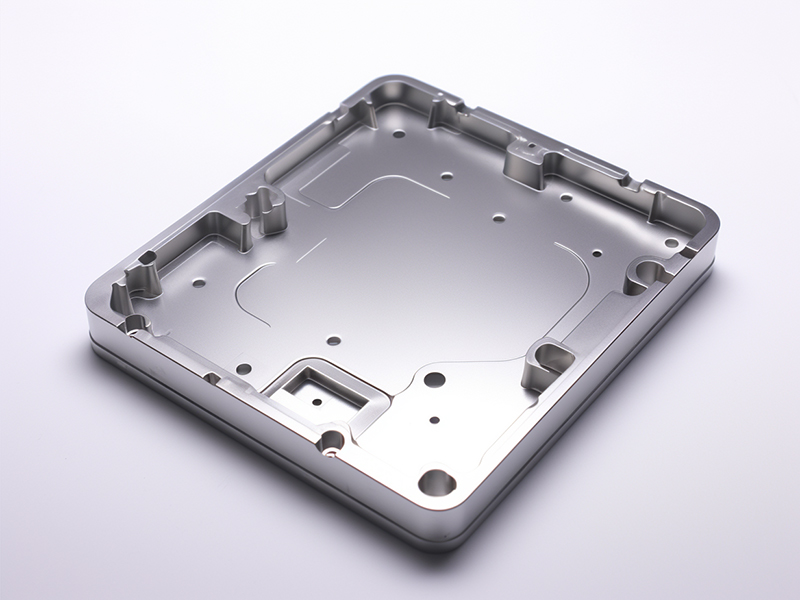

Electronic device housings are one of our specialties. From smartphone casings to industrial control equipment enclosures, camera bodies to communication device housings, we deliver optimal solutions. Particularly in the 5G communication equipment sector, our high-precision machining capabilities ensure signal transmission quality and device stability.

For industrial equipment housings, we provide protective enclosures for various sensors, controllers, and measuring instruments. These housings must not only offer superior protection but also consider ease of installation and maintenance. Our design team delivers optimized structural solutions tailored to clients’ specific requirements.

Outdoor protective housings require enhanced weather resistance and protection levels. Using specialized materials and surface treatment processes, we ensure products perform reliably in harsh environments. From waterproof boxes to outdoor surveillance equipment enclosures, we offer IP67 and higher protection grade solutions.

Chapter 3: The Art of Materials — Selecting the Right Metal

Material selection directly impacts product performance and cost. Xiamen Goldcattle offers a range of high-quality materials for clients to choose from:

Aluminum alloy is one of the most commonly used housing materials. Different grades such as 6061, 6063, 6082, and 7075 each have unique characteristics. 6061 aluminum alloy provides balanced performance for most applications, while 7075 aluminum alloy offers higher strength for demanding scenarios. Aluminum alloy advantages include light weight, excellent thermal conductivity, and ease of machining and surface treatment.

Stainless steel is renowned for its exceptional corrosion resistance and strength. 304 stainless steel suits general environments, while 316 stainless steel offers superior seawater corrosion resistance — ideal for marine environments and medical devices. Though heavier, stainless steel housings are perfect for applications requiring high protection levels and long service life.

Magnesium alloy is the top choice for lightweight designs, weighing approximately 30% less than aluminum alloy while maintaining similar strength. It is particularly suitable for weight-sensitive products like laptops and tablets.

Titanium alloy is the preferred material for high-end products. With excellent strength-to-weight ratio, corrosion resistance, and biocompatibility, it is widely used in aerospace and medical device industries.

Copper and brass are commonly used for applications requiring good electrical conductivity or decorative appeal. Copper offers excellent conductivity for electromagnetic shielding housings, while brass provides good machinability and aesthetic effects.

Chapter 4: The Art of Precision Machining — Perfect Integration of Technology and Craftsmanship

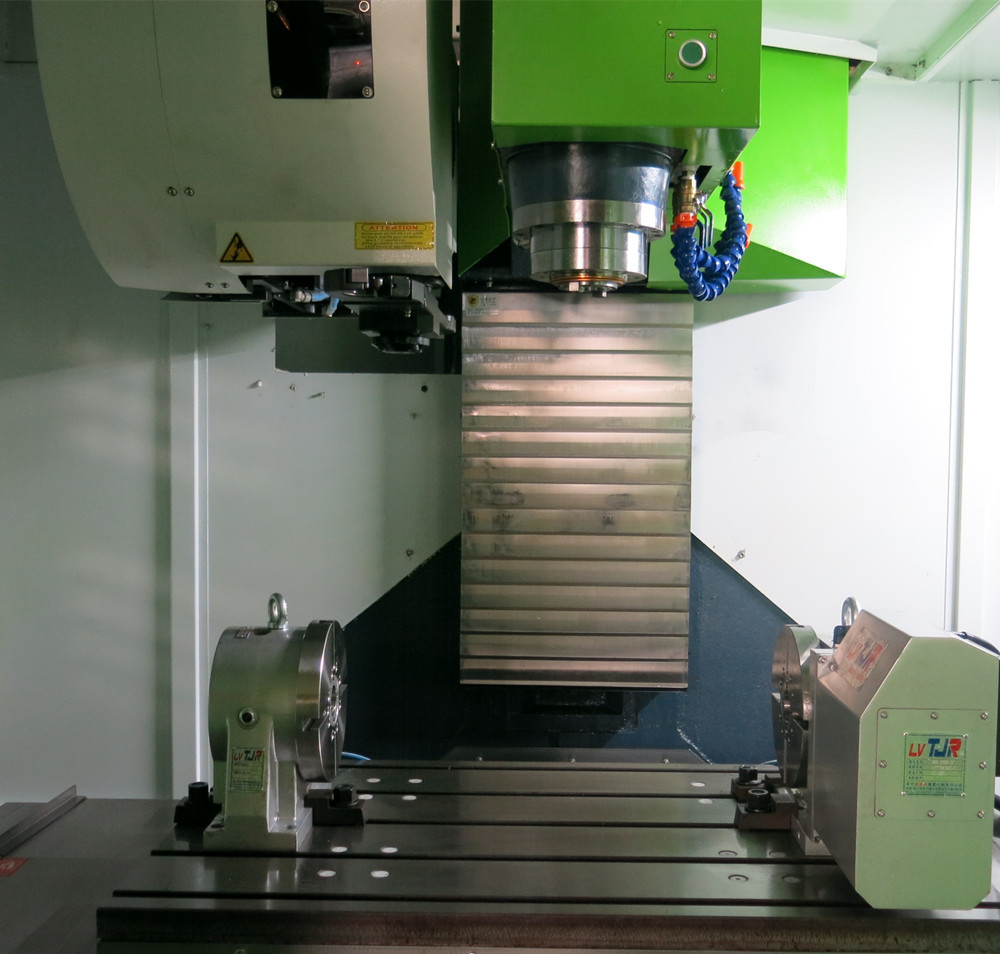

CNC machining is a precise art that requires advanced equipment and extensive experience. Xiamen Goldcattle boasts state-of-the-art machining facilities and a skilled technical team, capable of handling various complex machining tasks:

Multi-axis machining technology is one of our core competencies. 4-axis and 5-axis machining centers enable the processing of complex curved surfaces and deep cavities, significantly improving efficiency and precision. Especially for housings with complex internal structures, multi-axis machining completes multiple surface operations in one setup, reducing clamping times and enhancing accuracy.

Thin-wall machining presents a technical challenge. Thin-walled structures (0.8–1.5mm) are prone to deformation during processing. We employ specialized machining strategies and fixture designs to ensure machining precision and surface quality of thin-walled components.

Precision slot, hole, and interface machining directly affects product assembly performance. Using high-precision tools and processes, we guarantee dimensional and positional accuracy of various interfaces, facilitating subsequent assembly.

Heat dissipation structure machining is critical for electronic device housings. We can machine various complex heat sink structures to improve heat dissipation efficiency and ensure long-term stable equipment operation.

Chapter 5: The Magic of Surface Finishing — Enhancing Product Appeal

Surface finishing not only influences product appearance but also directly impacts performance and service life. Xiamen Goldcattle offers a variety of surface treatment options:

Anodizing is the most common surface treatment for aluminum alloy. We provide natural, black, hard anodizing, and various colored anodizing finishes. Anodizing not only improves corrosion and wear resistance but also offers a wide range of color choices.

Sandblasting, brushing, and polishing alter surface texture and luster. Sandblasting creates a uniform matte effect; brushing produces elegant linear textures; polishing achieves a mirror-like shine.

Powder coating and painting provide richer color options and higher protection performance. We offer powder coatings in various colors and textures to meet different design requirements.

Electroplating processes such as nickel and chrome plating enhance corrosion resistance and decorative appeal. Particularly for applications requiring conductivity or electromagnetic shielding, electroplating is an ideal choice.

Laser engraving enables product personalization. We can engrave intricate logos, text, or patterns on product surfaces to enhance brand recognition.

Chapter 6: Quality Assurance — Full-Cycle Control from Design to Delivery

Quality is the lifeline of an enterprise. Xiamen Goldcattle has established a comprehensive quality management system to ensure every product meets client requirements:

Dimensional tolerance control is the core of quality assurance. We achieve machining precision of ±0.02–0.05mm, far exceeding industry standards. For products with special requirements, we can achieve even higher precision levels.

Advanced testing equipment forms the foundation of quality control. We possess coordinate measuring machines (CMM), 2D vision measuring systems, surface roughness testers, and other advanced inspection equipment for comprehensive product testing.

Material certification and surface treatment testing ensure raw material and process quality. We conduct strict inspections on each batch of materials and perform multiple tests (salt spray, hardness, etc.) on surface treatment effects.

Comprehensive inspection reports provide quality assurance for clients. We deliver complete quality documentation including First Article Inspection (FAI) reports, Production Part Approval Process (PPAP) documentation, and batch sampling inspection reports, giving clients full confidence in product quality.

Chapter 7: Customization Services — Tailored Solutions for Clients

Every client has unique needs. Xiamen Goldcattle offers comprehensive customization services:

Size and shape customization is the most basic requirement. We can accurately replicate or improve designs based on client-provided drawings or samples.

Surface color and texture customization meets design requirements. From color matching to texture design, we provide professional advice and solutions.

Waterproof and sealing structure design is one of our specialties. With extensive waterproof design experience, we deliver optimized sealing solutions for clients.

Mounting hole design directly impacts assembly efficiency. We collaborate closely with client design teams to optimize hole layouts and improve assembly processes.

Logo customization helps clients enhance brand image. We offer various logo production processes, from laser engraving to screen printing, to meet different needs.

Chapter 8: Production Capacity and Lead Time — Balancing Efficiency and Quality

In today’s competitive market, rapid response and timely delivery are crucial. Xiamen Goldcattle possesses strong production capabilities and flexible scheduling:

Rapid prototyping completes sample production within 3–7 days, helping clients quickly validate designs and conduct market testing. We use advanced rapid prototyping technology to ensure consistency between samples and final products.

Low-volume production (50–500 units) suits product trial production and market promotion stages. We respond quickly to low-volume requests with flexible production arrangements.

Mass production (1,000–50,000 units) demonstrates our scale advantages. Equipped with advanced production lines and comprehensive management systems, we ensure stability and consistency in mass production.

Global logistics services ensure timely product delivery worldwide. We have established long-term partnerships with renowned logistics providers to offer safe and efficient logistics solutions.

Chapter 9: Cost Optimization — Balancing Value and Price

Cost control is a key concern for every client. Xiamen Goldcattle helps clients optimize costs through multiple approaches:

Processing time optimization is critical for cost reduction. We improve machining efficiency and lower costs by optimizing processes and tool paths.

Material cost control requires balancing performance and cost. Our engineers recommend the most suitable materials based on client needs, meeting performance requirements while controlling costs.

Surface treatment costs vary significantly by process. We recommend the most cost-effective surface treatment solutions based on application environments and appearance requirements.

Volume effects are an important factor in cost reduction. Unit costs decrease significantly with increased production volume. We encourage clients to adopt mass production for better cost-effectiveness.

Chapter 10: Starting Cooperation — How to Request a Quote

Cooperating with Xiamen Goldcattle is straightforward. Clients only need to provide the following information:

Detailed drawings are essential for quoting. Both 2D drawings (PDF format) and 3D models (STEP or IGES format) are acceptable. Drawings should include complete dimensions, tolerances, and material requirements.

Material selection directly impacts cost and performance. Clients can choose the most suitable materials based on our recommendations.

Surface treatment requirements should be clearly specified, including color, texture, and protection grade.

Precision and tolerance requirements should be determined based on actual needs. Excessively high precision requirements increase costs, and we assist clients in defining reasonable specifications.

Quantity information includes sample quantity and mass production volume. This helps us develop optimized production plans and quotes.

Conclusion: Choose Xiamen Goldcattle — Quality and Service Guaranteed

In the world of precision manufacturing, every detail determines product success. With 26 years of professional experience, advanced equipment, exquisite technology, and high-quality service, Xiamen Goldcattle Industrial & Trade Co., Ltd. is your trusted partner for custom CNC metal housing machining.

We not only deliver high-quality products but also provide comprehensive technical support and solutions. From product design to mass production, technical consultation to after-sales service, we are committed to serving you wholeheartedly.

Choose Xiamen Goldcattle for the perfect combination of quality and service. Let’s cooperate to create a better future!

Xiamen Goldcattle Industrial & Trade Co., Ltd. — Your Trusted Precision Manufacturing Expert