In the Custom CNC parts processing industry, the burr problem on the metal surface is a thorny issue. What exactly is this CNC metal burr problem that both customers and manufacturers dislike? Today, Xiamen Goldcattle will discuss this problem with you:

I. What are CNC Metal Parts Burrs?

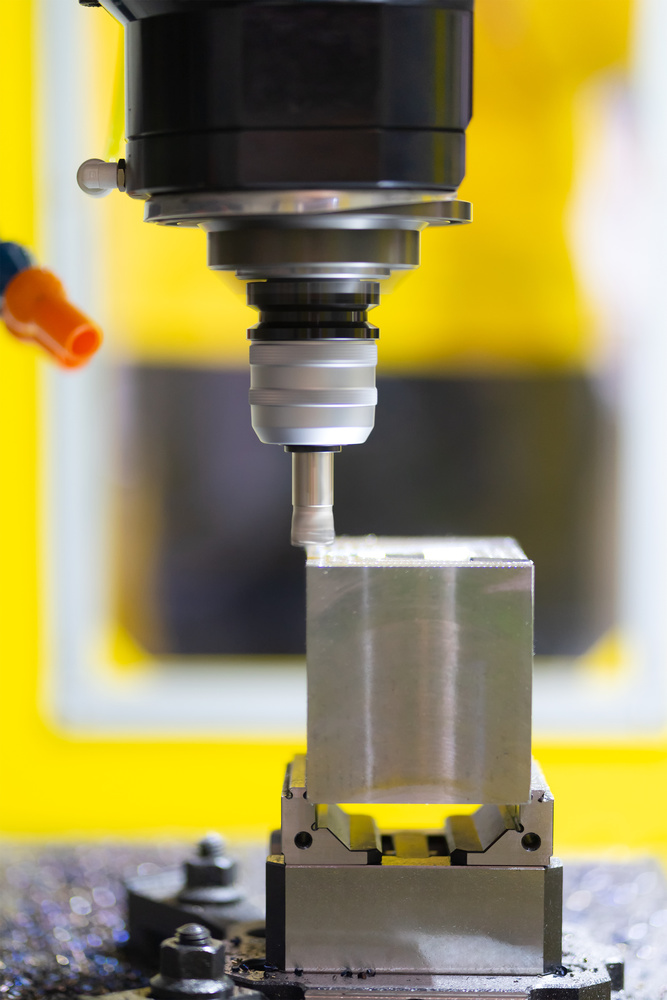

CNC metal parts burrs refer to excess metal protrusions or flashes formed on the surface or edges of metal materials after CNC machining processes such as cutting and milling.

Causes of Occurrence:

- Tool wear reduces cutting edge sharpness and increases cutting force

- Unreasonable cutting parameters, such as excessively high cutting speed or feed rate

- Material characteristics influence, with more ductile materials being more prone to burr formation

- Improper machining processes, such as unreasonable tool path design or insufficient cooling and lubrication

- Inadequate machine tool precision or fixture positioning deviations causing uneven cutting forces

- Unstable tool installation or unreasonable geometric angles

II. Impacts of CNC Metal Parts Burrs

Burrs directly damage product performance, assembly efficiency, and operational safety:

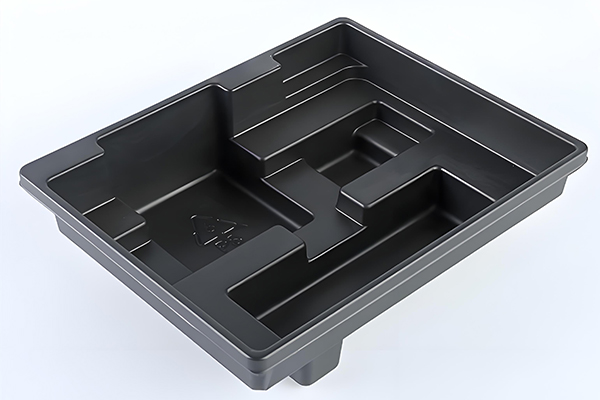

- Affect assembly precision, causing abnormal part fit clearances and reducing equipment operational stability

- Scratch adjacent part surfaces, damaging sealing performance and increasing wear risks

- Pose safety hazards, easily scratching operators or affecting electronic component conductivity

- Reduce product appearance quality, failing to meet high-end manufacturing precision requirements

- Increase subsequent processing costs and extend production cycles

- Impact product service life and reduce overall performance

III. How to Prevent CNC Metal Parts Burrs

Achieve burr prevention through optimizing the entire machining process:

- Select high-precision tools and regularly inspect wear conditions, replacing them promptly

- Optimize cutting parameters based on material characteristics, precisely matching spindle speed and feed rate

- Utilize 5-axis machining equipment to enhance cutting stability and precision control

- Design reasonable part structures with process chamfers or relief grooves

- Implement strict machine tool calibration and maintenance to ensure equipment precision

- Optimize cooling and lubrication systems to reduce cutting temperatures and tool wear

IV. CNC Metal Parts Burr Removal

Adopt efficient and precise removal methods for existing burrs:

- Mechanical grinding: Manual or automated grinding using grinding wheels, files, and other tools

- Chemical deburring: Remove micro-burrs through chemical solution corrosion without damaging the substrate

- Electrochemical deburring: Precisely remove burrs from complex structures using electrolytic reactions

- High-pressure water jet deburring: Suitable for precision parts without mechanical stress effects

- Vibratory finishing: Remove burrs in batches through friction between finishing media and parts

- Robotic automated grinding: Achieve high-precision, high-efficiency burr removal

V. How to Prevent CNC Metal Parts Burrs

Achieve burr prevention through optimizing the entire machining process:

- Select high-precision tools and regularly inspect wear conditions, replacing them promptly

- Optimize cutting parameters based on material characteristics, precisely matching spindle speed and feed rate

- Utilize 5-axis machining equipment to enhance cutting stability and precision control

- Design reasonable part structures with process chamfers or relief grooves

- Implement strict machine tool calibration and maintenance to ensure equipment precision

- Optimize cooling and lubrication systems to reduce cutting temperatures and tool wear

VI. CNC Metal Parts Surface Machining Techniques

Advanced surface machining processes simultaneously improve precision and finish while reducing burr formation:

- Precision milling: Adopt high-speed cutting technology to reduce material plastic deformation

- Grinding processes: Achieve surface flatness through fine grinding with grinding wheels

- Polishing treatments: Mechanical or chemical polishing to remove micro-defects

- Electrochemical machining: Suitable for complex surfaces to achieve high-precision surface forming

- Laser machining: Non-contact cutting reduces burrs and heat-affected zones

- Honing processes: Improve inner hole surface quality and reduce burr formation

VII. Common Defects in CNC Metal Parts

- Dimensional deviations: Caused by machine tool precision or programming errors; require regular equipment calibration and programming optimization

- Surface scratches: Caused by tool residues or clamping collisions; strengthen process protection and tool inspection

- Deformation issues: Caused by cutting heat or excessive clamping force; adopt cooling processes and reasonable clamping methods

- Porosity defects: Caused by insufficient material purity or improper processing parameters; strictly control raw material quality and adjust processes

- Excessive roughness: Caused by unreasonable cutting parameters; optimize tool and machining parameter combinations

- Surface cracks: Caused by material stress or improper temperature control; strengthen material pre-treatment and process control

VIII. CNC Metal Parts Machining Process

- Drawing analysis: Interpret part design requirements and precision standards

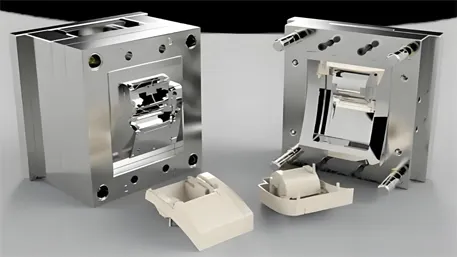

- Material selection: Choose appropriate materials such as aluminum alloy or stainless steel based on application

- Programming design: Write CNC machining programs and plan tool paths

- Clamping and positioning: Secure workpieces to ensure precise machining benchmarks

- Trial cutting: Small-batch trial production to verify program and parameter rationality

- Mass production: Initiate automated machining with real-time monitoring of operational status

- Quality inspection: Use precision instruments to inspect dimensions and surface quality

- Post-processing: Deburring, surface treatment, and other optimization processes

- Final inspection: Verify against standards before packaging and shipment

IX. Advantages of Online Custom CNC Machined Parts

- Customized to requirements, precisely matching personalized design needs

- Simplified communication process for quick quotation and production plan acquisition

- Shortened production cycle supporting small-batch rapid delivery

- Full-process visual tracking to monitor production progress in real-time

- Professional technical support to optimize design solutions and enhance product performance

- Transparent quality standards compliant with international certification specifications

- Reduced inventory costs and avoided backlog waste

- Flexible response to market changes with rapid customer demand fulfillment

X. Xiamen Goldcattle Online Custom CNC Parts Service Introduction

With 26 years of machining experience and national high-tech enterprise qualification, Xiamen Goldcattle provides professional CNC machining services:

- 26 years of machining experience with national high-tech enterprise certification

- Equipped with 5-axis machining equipment achieving precision up to ±0.005mm

- Certified with ISO 9001, SGS, CE, and other international authoritative certifications

- Supports multi-material processing including aluminum alloy, stainless steel, and copper alloy

- Provides one-stop solutions from design optimization to mass production

- Professional engineering team offers full-process technical support and process guidance

- Follows “high quality, high efficiency, integrity service” principles ensuring delivery timeliness

- Supports customization from drawings or samples with comprehensive after-sales technical service

Whether you need to solve burr issues, pursue high-precision machining, or have personalized CNC parts customization requirements, Xiamen Goldcattle can empower you with 26 years of industry experience and advanced processes. Upload your drawings or consult for details now, and we will provide you with accurate quotations, professional process optimization suggestions, and efficient delivery services. Let every part meet your exacting standards and work together to build high-end manufacturing core competitiveness!