In recent years, with the continuous advancement of the digital manufacturing and Industry 4.0 trends, 3D printing technology has gradually shifted from prototype making to mass – scale, personalized production. As an important participant in this transformation trend, Xiamen Goldcattle, with its advanced 3D printing equipment, diverse material options, and flexible customization services, is providing efficient and precise 3D printing solutions for various industries.

I. Precise Customization, Quick Response to Market Demands

Xiamen Goldcattle’s 3D printing services mainly focus on meeting customers’ needs for personalized and small – batch production. Whether it is metal, non – metal, resin, ceramic, or other materials, customized production can be achieved through a variety of 3D printing technologies, including FDM, SLA, SLS, DLP, and metal 3D printing. The company promises to complete the delivery from sample making to mass production in as fast as 1 – 7 days, greatly shortening the cycle from design to finished product and providing strong support for enterprises to shorten the time – to – market of their products.

“Under the current backdrop of the accelerated digital transformation of the manufacturing industry, the ability for customized production has become an important factor for enterprises to seize market opportunities,” said a relevant person in charge of Xiamen Goldcattle. “We rely on the ISO9001 quality management system to ensure that every printed product meets high – standard and high – precision requirements.”

II. Technical Strength and Quality Control

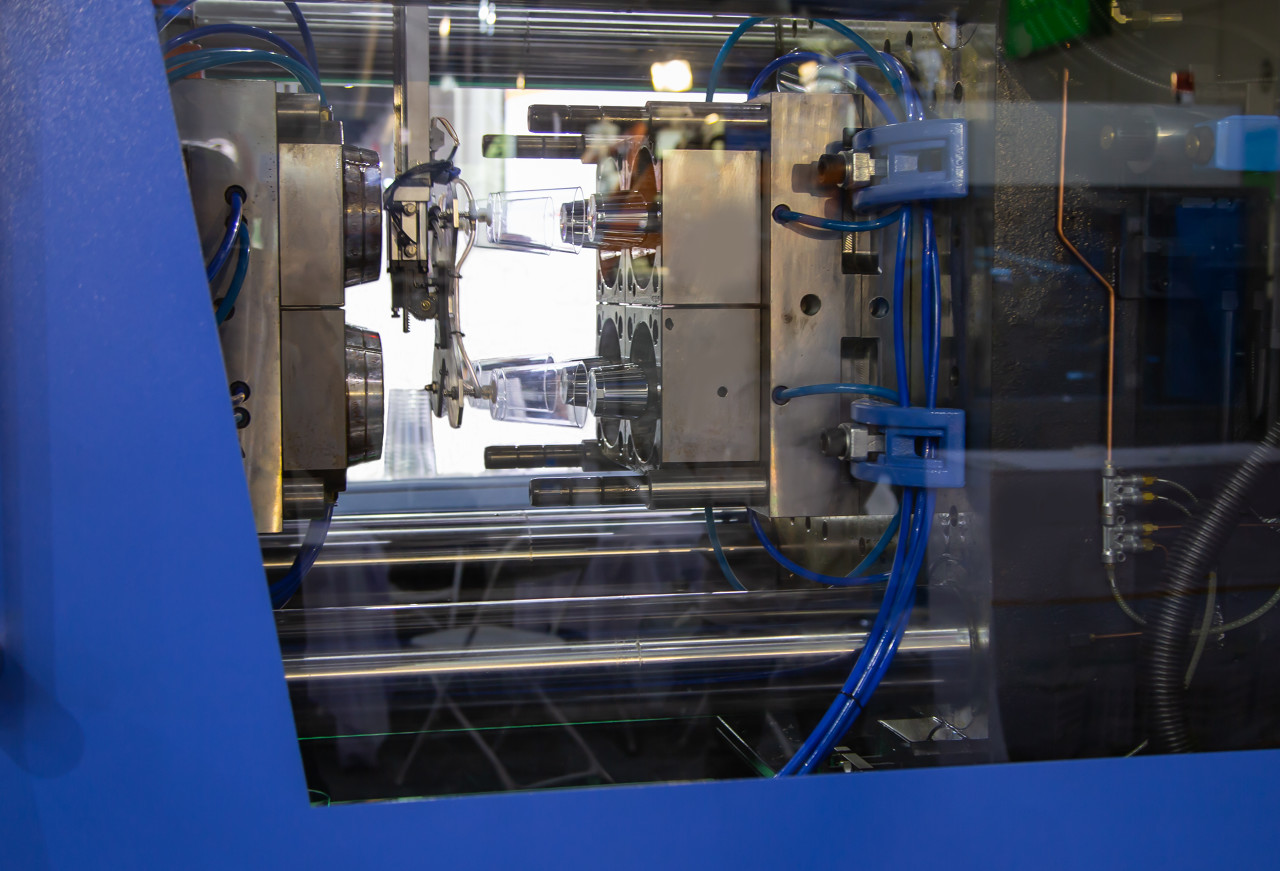

Xiamen Goldcattle has invested a large amount of resources in introducing advanced 3D printing equipment, covering various processes such as FDM (Fused Deposition Modeling), SLA (Stereolithography Apparatus), SLS (Selective Laser Sintering), as well as metal and ceramic 3D printing. Among them, the FDM technology, with its material diversity and cost – effectiveness, is suitable for industrial samples and functional verification. The SLA process, on the other hand, is widely used in the manufacture of visual prototypes and high – precision parts due to its high resolution and smooth surface effect.

In addition, Xiamen Goldcattle adopts a strict quality control process. Every link, from the pre – treatment of design files, material inspection to post – processing such as polishing, is carefully managed to ensure that products can meet customers’ diverse needs in terms of structure, appearance, and function.

III. Applications in Multiple Fields, Serving a Wide Market

Xiamen Goldcattle’s customized 3D printing services have achieved remarkable results in multiple industries, including but not limited to:

Industrial Manufacturing: Provide rapid printing of parts from prototypes to functional components for machinery, automotive, and electronics enterprises, reducing development costs and the difficulty of mold making.

Medical Field: Utilize high – precision SLA and metal printing technologies to provide customized solutions for medical devices, surgical pre – planning models, and personalized implants.

Cultural and Creative Industries: Meet the personalized needs of industries such as film and television animation, handicraft design, and customized jewelry, achieving a perfect integration of art and technology.

Home Life: Through rapid prototyping and small – batch customization services, assist in the efficient conversion of home products and creative products from design to production.

IV. Future Outlook: From Customized Services to Intelligent Manufacturing

Facing the growing market demand for high – quality, short – cycle customized products, Xiamen Goldcattle is actively exploring the path of deeply integrating artificial intelligence with 3D printing processes. By introducing a digital management platform and an intelligent parameter optimization system, the company has not only made breakthroughs in improving printing efficiency and reducing material waste but also further expanded the application boundaries in complex structure and multi – material printing.

“In the future, we plan to provide customers with one – stop services from design, simulation to production through building an integrated cloud manufacturing platform, truly realizing’manufacturing on demand,'” the person in charge introduced.

Conclusion

Xiamen Goldcattle’s customized 3D printing services not only provide customers with high – precision and high – quality products but also strongly support the intelligent transformation of the entire manufacturing industry. In the context of industrial upgrading and the increasing demand for personalized customization, Xiamen Goldcattle, with its leading technology and flexible service model, is helping enterprises in various fields to achieve the leap from traditional production to digital and intelligent manufacturing, injecting new vitality into the future market.