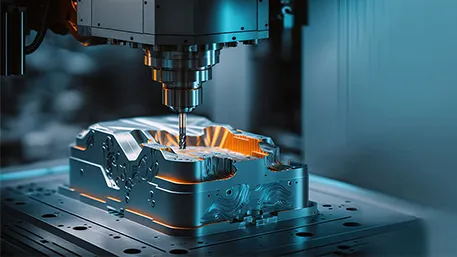

— Centered on Precision Machining Technology, Creating an “Acceleration Engine” for Product Innovation

I. Technical Advantages: Why Do Global TOP 500 Enterprises Choose CNC Prototypes?

±0.005mm Precision Standard, Breaking Through Functional Verification Bottlenecks

CNC processing achieves micron-level forming of complex curved surfaces through five-axis linkage technology, and its prototype parts can be directly used for assembly tests and stress analysis. For example, an orthopedic implant developed by a certain medical device enterprise verified the biomechanical properties through a CNC titanium alloy prototype, shortening the product’s time to market by 60%.

Over 200 Authentic Materials Restoration, Eliminating Process Adaptation Risks

Compared to the material limitations of 3D printing, CNC can directly process mass-production-level materials such as aluminum alloys, PEEK, and stainless steel, ensuring the mechanical property consistency between prototype parts and final products. A certain new energy vehicle battery box adopted a CNC aluminum alloy prototype for collision simulation, successfully avoiding shrinkage porosity defects in the die-casting process.

72-hour Rapid Delivery, Agile Response to Design Iterations

Through a modular tool library and an intelligent CAM programming system, the production cycle of CNC prototypes is 3-5 times faster than traditional processes. In the development of TWS headphones by a certain consumer electronics giant, three structural iterations were achieved per week, and the on-time delivery rate at key nodes reached 99.5%.

II. Industry Applications: Closed-loop Services from Concept Verification to Small Batch Pilot Production

Automotive Industry: Engine cylinder block functional prototypes, tooling fixtures for carbon fiber interior parts

Medical Devices: Dynamic simulation parts of surgical instruments, fatigue test parts of degradable bone plates

Smart Hardware: Metal middle frames of smart watches, heat dissipation structures of AR/VR devices

Industrial Equipment: Precision gears of robot joints, flow verification models of hydraulic valve bodies

(Industry Data: The global market size of CNC prototypes will reach 32 billion US dollars in 2024, with the automotive and medical fields contributing over 45% of the share)

III. Enterprise Service Ecology: Six Value-added Systems Beyond Processing

Design Optimization Services

Based on the DFM (Design for Manufacturability) principle, processing deformation and tool interference problems are avoided in advance. Through topological optimization, a certain unmanned aircraft propeller project reduced weight by 23%

Provide a material selection database covering 12 performance parameters such as strength/thermal conductivity/corrosion resistance, etc.

2. Full-process Digital Management and Control

The cloud collaboration platform updates 3D drawings in real-time, supporting online annotations and version management

Equipped with coordinate measuring machines and industrial CT scans, key dimension inspection reports are automatically generated

3. Small Batch Pilot Production Solutions

Flexible manufacturing units achieve elastic production capacity of 50 – 5,000 pieces, and the unit cost is reduced by 40% compared to traditional methods

Provide post-treatment processes such as anodic oxidation and micro-arc oxidation

IV. Customer Value Demonstration: Three Guarantees for Choosing Us

Technical Certification Endorsement: ISO 13485 medical system certification, IATF 16949 automotive industry standard

Full-industry-chain Resources: Establish strategic cooperation with Baosteel and Sandvik, optimizing material procurement costs by 12%

Intellectual Property Protection: Military-grade data encryption system, zero customer confidentiality leakage complaints in the past three years

Conclusion

Driven by both intelligent manufacturing and personalized customization, CNC prototype manufacturing is upgrading from an auxiliary tool to a strategic resource for product innovation. With the core concept of “Precision is the Voice”, we construct a full value chain service system covering design – verification – pilot production, helping customers seize market opportunities.

Click on the official website to make an appointment with an engineer, and you can get the “Full-process Guide to CNC Prototype Development” and exclusive preferential solutions for free – Let your creativity land at industrial-level precision with acceleration!