Xiamen Goldcattle CNC machining parts supplier, as the industry leader, with excellent technical strength, perfect customized service process and the relentless pursuit of quality, is leading the precision manufacturing to new heights. Today, let’s go into the world of Goldcattle and explore how it shines in the field of CNC machining.

1. Craftsmanship, customized services show professional style

In Goldcattle, the birth of each CNC machined part is a profound interpretation of the word “craftsmanship”. We know that customized service is not only to meet the basic needs of customers, but also a positive response to the pursuit of personalization and differentiation. Therefore, Goldcattle has set up a professional team consisting of senior engineers, designers and project management experts, who, with rich industry experience and keen market insight, are able to quickly capture the unique needs of customers and transform them into precise design solutions.

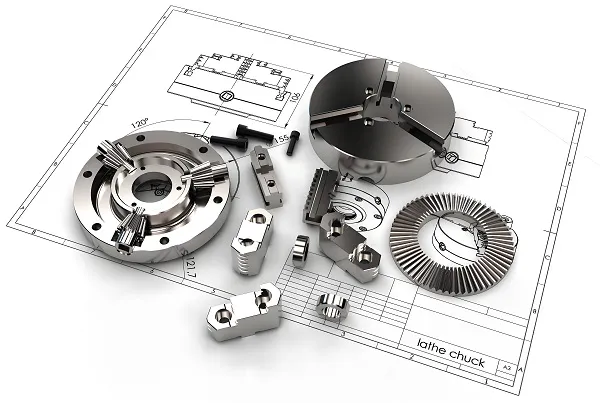

From initial consultation to schematic design, from material selection to process development, Goldcattle’s customized service process is rigorous and efficient. We use advanced CAD/CAM software system for 3D modeling and simulation analysis to ensure the accuracy of the design scheme; at the same time, through close communication with the customer, we continuously adjust and optimize the design until we reach a mutually satisfactory result. This customer-centered service model makes Goldcattle stand out in the fierce market competition and win the trust and praise of many customers.

2.Precision manufacturing, technical strength cast quality cornerstone

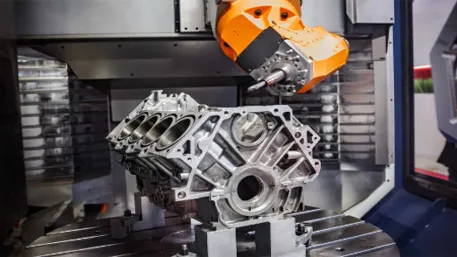

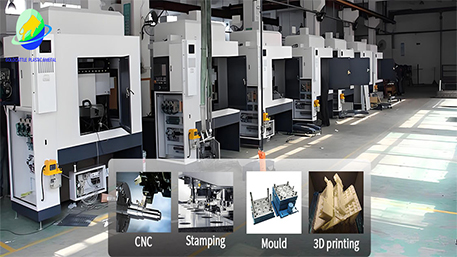

As a leader in the field of CNC machining, Goldcattle has advanced machining equipment and exquisite manufacturing technology. We have introduced a number of high-precision CNC machine tools, which are integrated with advanced CNC system, automatic tool changer and precision measurement system, which can realize the precision machining of complex parts and ensure the machining accuracy up to micron level. In addition, Goldcattle also focuses on technological innovation and research and development, and constantly introduces new technologies and techniques to improve machining efficiency and product quality.

In the process of machining, Goldcattle strictly implements ISO quality management system standards, and carries out strict control and inspection on every link. From the raw materials into the warehouse to the finished product out of the warehouse, each process has gone through strict quality control to ensure that each product meets customer requirements and industry standards. It is this relentless pursuit of quality that makes Goldcattle’s CNC machined parts win a good reputation in the market.

3.Depth and breadth of customized service

Goldcattle deeply understands that every customer is unique and their needs are equally unique. Therefore, our customized service is not only limited to the product itself, but also extends to the whole cooperation process. From the first contact, our professional team will have in-depth communication with customers to explore and understand their real needs, whether it is special requirements on the function, or personalized design on the appearance, we strive to achieve a precise grasp.

In the depth of customized services, Goldcattle, with rich industry experience and strong technical strength, can provide customers with one-stop solutions from conceptual design to finished product delivery. Our designers and engineers work closely together to combine our clients’ creativity with our expertise to create products that meet both functional needs and artistic aesthetics.

And in terms of breadth, Goldcattle’s customization services cover a wide range of industry sectors including, but not limited to, aerospace, automotive manufacturing, medical devices, precision instruments, and more. No matter how complex your project is and how special your needs are, we are confident and capable of providing customized solutions that meet your expectations.

4.Efficient and Flexible Customization Process

Goldcattle’s customization process is known for its efficiency and flexibility. We understand that in the fast-changing market environment, time is money and efficiency is life. Therefore, we constantly optimize our internal processes and improve the efficiency of teamwork to ensure that every order can be completed in the shortest possible time.

First of all, we adopt advanced project management tools to track and manage orders throughout the process. From order receipt, demand analysis, design confirmation, production arrangement to finished product inspection, logistics and distribution, every step of the process has been computerized and digitally managed. This not only improves the speed and accuracy of information transfer, but also ensures the seamless connection between each link.

Secondly, Goldcattle’s customization process is highly flexible. We are able to adjust the production plan and process in time according to the specific needs of customers and market changes. Whether it is increasing or decreasing production quantities, or changing product specifications or materials, we are able to respond quickly and meet our customers’ needs.

In addition, Goldcattle focuses on communication and feedback with our customers. Throughout the customization process, we always keep in close contact with our customers, report the production progress and problems encountered in a timely manner, and invite our customers to participate in the decision-making process of key aspects. This open and transparent communication not only enhances customer trust and satisfaction, but also provides us with opportunities for continuous improvement.

5.High-quality products, win market reputation

Goldcattle’s high quality products are the cornerstone of our reputation in the market. We know that product quality is the lifeline of enterprise survival and development. Therefore, we always put product quality in the first place, start from the source, and carry out strict quality control and testing for each link.

In the production process, we have established a perfect quality management system and testing process. From the incoming inspection of raw materials, the process inspection of the production process to the final inspection of the finished products, each link is equipped with professional testing equipment and personnel to ensure the stability and reliability of product quality. At the same time, we have also established a quality traceability mechanism, numbering and recording each product so that it can be quickly traced and dealt with in case of quality problems.

It is this unremitting pursuit and strict control of product quality that makes Goldcattle’s CNC machined parts win wide acclaim and praise in the market. Whether it is from the appearance quality, dimensional accuracy or performance performance, our products have reached the industry leading level, won the trust and recognition of customers.

6.Customized service to meet diversified customer needs

In addition to exquisite craftsmanship and high-quality products, Goldcattle is also known for its excellent customized services. We are well aware that in the fast-changing market environment, customers’ needs are also changing and evolving. Therefore, we always put our customers’ needs first and are committed to providing them with more personalized and customized services.

Our customized services cover every aspect from product design, process development to production and processing. We conduct in-depth communication and exchanges with our customers to understand their specific needs and expectations, and develop detailed design programs and process routes accordingly. At the same time, we also provide sample trial production and testing services so that customers can verify and validate their products before formal production.

In the process of customization service, we focus on close cooperation and interaction with customers. We have established a specialized customer service team and technical support team to provide customers with technical advice and solutions at any time. At the same time, we also regularly visit and communicate with our customers to understand the use of products and customer feedback, so that we can continuously improve and optimize the quality of service and product performance.

1. What are the advantages of CNC machining over traditional machining?

A: CNC machining has significant advantages over traditional machining. First of all, CNC machining is highly accurate and can realize micron-level machining to meet the needs of high-precision parts. Secondly, high processing efficiency, high degree of automation, can significantly shorten the production cycle. In addition, CNC machining also has the characteristics of strong flexibility and wide adaptability, and can process a variety of complex shapes and materials.

2. How to ensure the dimensional accuracy and surface quality of CNC machined parts?

Answer: Ensuring the dimensional accuracy and surface quality of CNC machined parts requires efforts in many aspects. First of all, select high-precision CNC machining equipment and advanced measuring instruments to ensure the stability and accuracy of the machining process. Secondly, rationally design the machining process and select cutting parameters to avoid excessive or small cutting force resulting in dimensional deviation and surface roughness. In addition, regular maintenance and repair of equipment, keep the equipment in good condition is also an important factor to ensure the quality of machining.

3. CNC machining parts delivery cycle is how long?

Answer: The delivery cycle of CNC machined parts is affected by a variety of factors, including the complexity of the parts, the number of machining, equipment utilization and production arrangements. Generally speaking, for simple parts and small quantities, the lead time is relatively short; while for complex parts and large quantities, the lead time may be longer. The specific delivery cycle should be determined by negotiation according to customer demand and the actual situation.

4. How is the price of CNC machined parts determined?

A: The price of CNC machined parts is affected by a variety of factors, including the material cost of the part, the difficulty of machining, machining time, equipment depreciation and labor costs. Generally speaking, we will be based on the drawings or samples of the parts for a detailed quotation accounting, and take into account the market competition and customer demand to give a reasonable price. The specific price should be determined by mutual negotiation.