In the highly competitive field of customized machinery, Xiamen Goldcattle Plastic & Metal Products Co., Ltd. has become a leader in the industry by virtue of its excellent injection mold manufacturing capability and profound industry accumulation. As a leading company focusing on the design and manufacture of plastic injection molds, we always adhere to the core concept of “rigorous, scientific and data-supported” to provide customers with one-stop, high-quality injection mold solutions.

1.Company Profile

Xiamen Goldcattle was founded in 1999, with registered capital of 10 million RMB and paid-up capital of 10 million RMB, which demonstrates the company’s strong financial strength and sound operation foundation. The company is located in Xiamen Area of China (Fujian) Pilot Free Trade Zone, which is strategically located to facilitate the expansion of domestic and international markets and the efficient management of the supply chain. We are a comprehensive cnc injection mold manufacturer integrating R&D, design, production and sales, with a professional and skilled team to ensure the smooth progress and high quality delivery of every project.

2.Manufacturing strength

2.1 Advanced equipment and technology

Xiamen Goldcattle has introduced a number of international advanced CNC machining centers, high-speed precision engraving machines, EDM machines and injection molding machines, etc. These high-precision, high-efficiency production equipment provides a solid guarantee for the fine processing and high-quality production of molds. We adopt CAD/CAM/CAE integrated design and manufacturing technology to realize digitalization and intelligence from product design to mold manufacturing, which greatly improves the precision and efficiency of the molds.

2.2 Customization Capability

Customized service is one of Xiamen Goldcattle’s core competencies. We have an experienced design team that can provide personalized mold design solutions according to customers’ specific needs and product characteristics. Whether it is complex structural parts, precision electronic component housings, or large automotive parts, we can ensure the accuracy and durability of the molds with precise dimensional control, excellent material selection, and superb craftsmanship. Our customized services have covered a wide range of industry sectors, including automotive, electronics, home appliances, medical, etc., and have won the trust and praise of many customers.

2.3 Quality Control

We know that quality is the foundation for the survival of an enterprise. Therefore, Xiamen Goldcattle has established a perfect quality management system, from raw material procurement, production and processing to finished product inspection, every link is strictly controlled to ensure the stability and reliability of product quality. We have advanced testing equipment and professional quality inspectors, who are capable of comprehensively testing the precision, strength and wear resistance of the molds to ensure that the molds meet the standards required by customers.

3.Service Advantages

3.1 Rapid response

We emphasize on communication and collaboration with customers and provide fast response service. Whether it is pre-consultation, program design, or feedback during the production process, we can reply and solve the problems in the shortest time to ensure the smooth progress of the project.

3.2 All-round service

In addition to mold manufacturing, we also provide mold maintenance, upgrading and injection molding and other ancillary services. Customers can choose the appropriate combination of services according to their own needs, realizing one-stop procurement and service experience.

3.3 Continuous optimization

We continue to pay attention to the industry dynamics and technology development trend, and constantly optimize the product design, production process and service flow, and are committed to providing customers with more high-quality, efficient and convenient injection mold manufacturing services.

Xiamen Goldcattle Plastic & Metal Products Co., Ltd. has established a good brand image and reputation in the field of plastic injection mold manufacturing by virtue of its advanced equipment, exquisite technology, customized service and strict quality control system. In the future, we will continue to adhere to the core concept of “rigorous, scientific, data-supported”, continuous innovation, the pursuit of excellence, to provide customers with more high-quality and efficient injection mold manufacturing services.

Injection Mold Manufacturing FAQ

What is an injection mold?

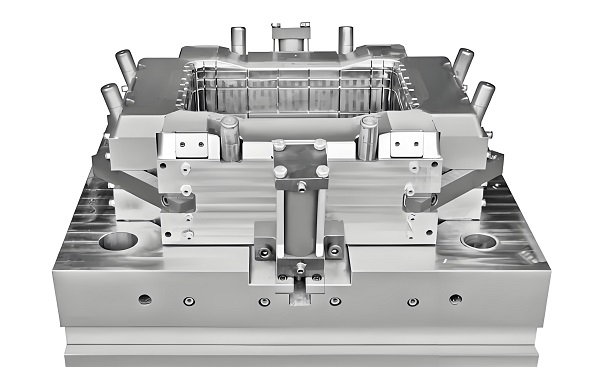

Plastic injection mold is a key tool for producing plastic products, it is through the injection molding process, the molten plastic material into the mold cavity, cooling and curing to get the desired shape of the plastic products. The injection mold consists of a front mold (convex mold), a rear mold (concave mold), and the related pouring system, guiding parts, launching mechanism and so on.

What are the main components of an injection mold?

Injection molds are mainly composed of the following parts:

Molding parts: including the moving and fixed mold parts, forming the internal and external shapes of the products.

Pouring system: The channel that guides the molten plastic from the injector nozzle to the mold cavity, including the main flow channel, diversion channel, gate and cold material cavity.

Guide parts: Ensure the mold can be accurately aligned when closing the mold, including guide pillar and guide sleeve, etc.

Push-out mechanism: After mold parting, the device to push out the products from the cavity, such as ejector pin, push plate and so on.

Temperature control system: control the temperature of the mold to meet the requirements of the injection molding process, usually including cooling waterway or heating element.

Exhaust system: Exclude the air and plastic volatile gases in the cavity during molding, often open the exhaust groove on the parting surface.