Acrylic CNC technology, an important branch in the field of mechanical customization, which combines the unique nature of acrylic materials with the precision of CNC machining technology, providing efficient, high-quality solutions for a number of industries. The following is a detailed analysis of acrylic CNC technology:

1. Acrylic material properties

Acrylic, scientifically known as polymethyl methacrylate (PMMA), is a thermoplastic with excellent transparency, toughness and processing performance. Its main characteristics include:

High transparency: transparency comparable to glass, light transmission rate of up to 92% or more.

Good processing performance: easy to cut, carve, heat bending and bonding.

Strong weather resistance: UV resistance, good weather resistance, not easy to aging.

Light and strong: half as light as glass, but high strength, not easy to break.

2.CNC Processing Technology

CNC processing technology, that is, computer numerical control (CNC) processing, is a modern manufacturing technology through computer programming to control the machine tool to automatically complete the processing task. Its features include:

High precision: capable of realizing micron-level machining accuracy.

High efficiency: high degree of automation, significantly reducing manual intervention and improving productivity.

Complex shape processing capability: capable of processing a variety of complex shapes and precision parts.

3. Acrylic CNC parts customization process

Acrylic CNC parts customization process is a delicate and complex process, which combines the characteristics of the acrylic material with the precision of CNC machining technology. The following are the main steps of the customization process:

● Requirements communication and design

Requirements communication: The customer and the manufacturer have an initial communication to clarify the specific needs of the part, including size, shape, color, transparency, quantity, and any special functional or decorative requirements.

Design: According to the customer’s needs, the designer draws detailed design drawings using professional design software. The design process needs to take into account the utilization rate of materials, the difficulty of processing and the aesthetics and practicality of the finished product.

● Material Selection and Purchase

Material selection: according to the design requirements and the use of parts, choose the appropriate acrylic material. There are many types of acrylic materials, including transparent, translucent, colored and other types, which need to be selected according to the actual needs.

Material Purchase: Purchase selected acrylic sheets or profiles from reliable suppliers to ensure that the quality of the material meets the standards.

● CNC Programming and Processing Preparation

CNC Programming: Convert the design drawings into program codes that can be recognized by the CNC machine. The programming process needs to consider the tool path, cutting speed, feed and other parameters to ensure machining accuracy and efficiency.

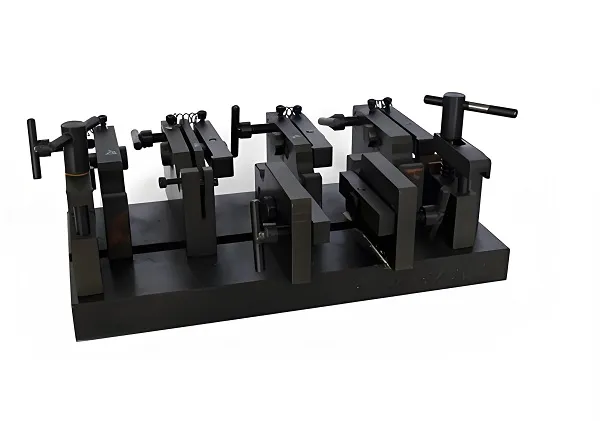

Preparation for machining: Prepare the tools, fixtures and other auxiliary tools required by the CNC machine tool, and debug and warm up the machine tool to ensure that the machining process is carried out smoothly.

● CNC machining

Cutting: Use the CNC cutting machine to cut the acrylic sheet accurately and form the basic shape of the part.

Engraving and punching: According to the design requirements, use the CNC engraving machine to engrave and punch the parts. Engraving creates complex patterns and textures, while punching is used to mount or connect other parts.

Hot Bending and Molding: Parts that need to be bent or molded are processed using a hot bending machine. By controlling the temperature and pressure, the acrylic sheet is formed into the desired curved shape during the hot bending process.

● Post-processing and inspection

Polishing and sanding: The processed parts are polished and sanded to eliminate surface burrs and unevenness and to improve the finish and aesthetics of the parts.

Quality Inspection: Conduct comprehensive quality inspection on the finished parts, including size, shape, color, transparency, surface quality and other aspects. Ensure that the parts meet the design requirements and customer expectations.

● Packaging and shipment

Packing: Properly pack the inspected parts to prevent them from being damaged during transportation. Packing materials should be selected to prevent shock, moisture and scratches.

Shipment: Ship the packaged parts to customers according to the time and method agreed in the contract. At the same time provide necessary transportation documents and after-sales service information.

4.Acrylic CNC application fields

Acrylic material is widely used in several industries due to its excellent performance. The following are the main industries in which acrylic materials are used and their specific application scenarios:

● Advertising industry

Billboards and display racks: acrylic is often used to make outdoor billboards, indoor display racks and display props due to its high transparency and good processing performance. These applications not only enhance the visual effect of advertising, but also facilitate installation and maintenance.

● Transportation industry

Vehicle doors and windows: Acrylic is used to make doors and windows in trains, automobiles and other transportation vehicles. Its high-strength, lightweight and weather-resistant features ensure passenger safety and visibility, while helping to reduce vehicle weight and fuel consumption.

Traffic signs: Acrylic is also commonly used to make traffic signs, road signs, etc. Because of its strong weather resistance, it can be used for a long time in harsh outdoor environments without fading or deformation.

● Medical industry

Medical equipment and instruments: acrylic is used in hospitals for guardianship room doors and windows, baby care boxes and a variety of surgical medical instruments. Its easy-to-clean, corrosion-resistant and high-transparency properties make the medical environment safer, more hygienic and comfortable.

● Construction industry

Windows and partitions: Acrylic is often used for windows, partitions and light roofs in buildings due to its high transparency, light weight and unbreakable properties. It not only provides good lighting effects, but also insulates against noise and wind, enhancing the aesthetics and comfort of the building.

Decoration and Lighting: Acrylic is also widely used in interior decoration and lighting, such as chandeliers, wall sconces, light boxes and so on. Its colorful colors and easy processing add a sense of art and modernity to the architectural space.

● Home industry

Home decorations: Acrylic can be used to make home decorations, such as photo frames, vases, lampshades and so on. Its beauty and durability are loved by consumers, adding a touch of sophistication and fashion to home life.

Industrial and electronic products

Instrument surface plate and cover: Acrylic can be used to make the surface plate and cover of large and small instruments, etc. It can protect the precision and stability of the instrument, and also improve the appearance and applicability of the instrument.

Display and touch screen protection plate: In the field of electronic equipment, acrylic is often used to make display and touch screen protection plate, in order to prevent scratches and impact damage to the equipment.

Retail and Display

Store windows and display cases: Store windows, exhibits and display cases are often made from acrylic to showcase products and keep them safe. Acrylic’s transparency and ease of processing make these display spaces more attractive and practical.

● Arts & Crafts

Art Production: Acrylic is widely used by artists to create canvases, sculptures and various works of art. Its high transparency and plasticity provide more possibilities and imagination for artistic creation.

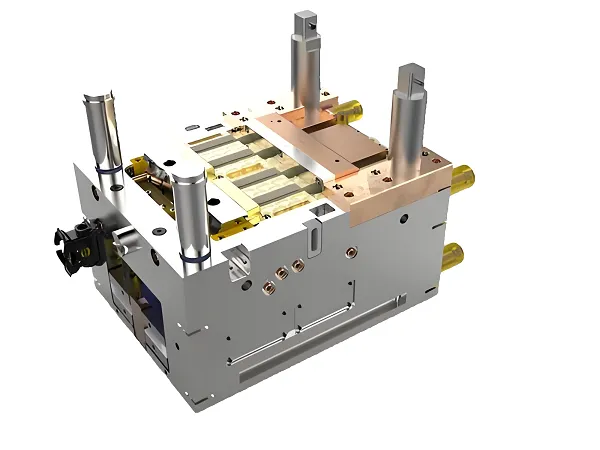

5. Acrylic CNC processing equipment

Acrylic CNC processing equipment mainly includes CNC engraving machines, laser cutting machines, heat bending machines and so on. These devices can achieve accurate processing of acrylic materials through precise program control. For example, CNC engraving machine can complete the cutting and engraving of complex shapes; laser cutting machine has become one of the preferred equipment for acrylic cutting with its high precision and non-contact processing characteristics.

Acrylic CNC Parts Customization FAQ

What are the advantages of acrylic CNC parts customization?

A: Acrylic CNC parts customization has the following significant advantages:

High precision: CNC machining technology can ensure that the size and shape of the parts are accurate and meet the needs of precision manufacturing.

Flexibility: it can be personalized according to the specific needs of customers, including complex patterns, shapes and sizes.

High machining efficiency: automated CNC machining equipment can dramatically increase productivity and shorten production cycles.

High material utilization: Through precise calculation and optimization of cutting paths, material waste can be reduced and costs lowered.

What is the most important part of the customization process?

A: In the customization process of acrylic CNC parts, the following links are particularly important:

Design link: Design is the starting point of the customization process, which directly determines the final form and function of the part. Therefore, it is crucial to communicate fully with customers to ensure that the design meets the needs.

CNC Programming: The accuracy and reasonableness of programming directly affects machining accuracy and efficiency. Experienced programmers are needed to program accurately according to the design drawings.

Quality Inspection: Quality inspection is the last hurdle to ensure that the quality of parts meets the requirements. Through comprehensive quality inspection, problems can be detected and corrected in time to avoid non-conforming products into the market.

How to choose the right acrylic material?

A: The following factors need to be considered when choosing the right acrylic material:

Transparency: Choose the right level of transparency according to the usage scenario and needs of the part. For example, parts that need to show the internal structure can choose high transparency materials.

Weather resistance: consider the use of parts of the environment, choose weather-resistant materials to ensure that the long-term use of non-deformation, non-fading color.

Processing performance: different types of acrylic materials in the processing performance differences. According to the processing method and requirements to choose the right material, you can improve processing efficiency and yield.