Introduction to Micro CNC Machining

Micro CNC machining represents the pinnacle of modern precision manufacturing technology, enabling the production of miniature components with micron-level accuracy. As industries continue to demand smaller, more precise parts for applications in medical devices, aerospace, and electronics, micro CNC machining has evolved to meet these challenges with advanced capabilities and innovative processes.

Industry Insight: According to 2025 market research, the global micro CNC machining market is projected to grow at a CAGR of 8.2% through 2030, driven by increasing demand in high-tech sectors requiring extreme precision components.

Technical Process & Methodology

Core Machining Principles

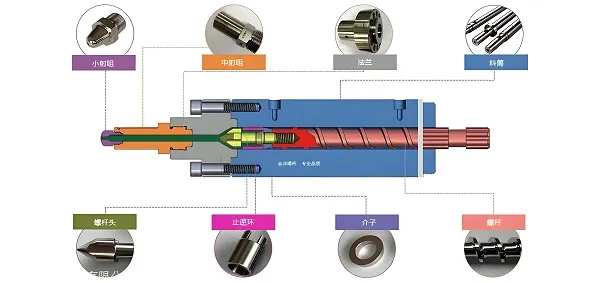

Micro CNC machining utilizes computer numerical control systems to manipulate cutting tools with extreme precision. The process involves several key stages, each critical to achieving the required accuracy and surface finish for micro-scale components.

Design & Programming

CAD modeling and CAM programming with tool path optimization

Material Preparation

Precision material selection and fixturing setup

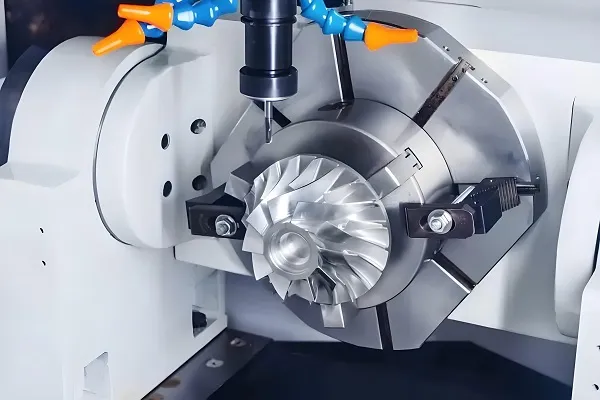

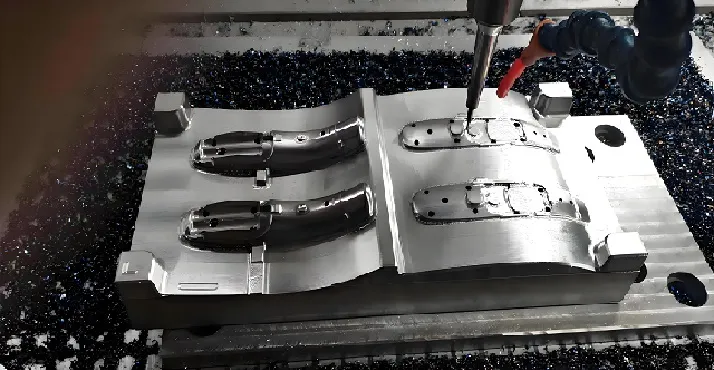

Precision Machining

High-speed cutting with micro-tools and advanced cooling

Quality Inspection

Metrological verification and dimensional validation

Advanced Techniques

Modern micro CNC machining incorporates several advanced techniques to achieve superior results:

- High-Speed Machining (HSM): Utilizes spindle speeds up to 80,000 RPM for improved surface finish

- Micromachining: Specialized tools with diameters as small as 0.1mm for intricate features

- Coolant Management: Through-spindle cooling for heat control and tool longevity

- Adaptive Control: Real-time adjustment of cutting parameters based on sensor feedback

Material Comparison & Analysis

Material Performance Metrics

| Material Type | Machinability Rating | Typical Precision (±μm) | Surface Finish (Ra μm) | Cost Index |

|---|---|---|---|---|

| Aluminum Alloy 6061 | Excellent (9/10) | 2-5 | 0.2-0.8 | Low (1.0) |

| Stainless Steel 316L | Good (7/10) | 3-8 | 0.4-1.2 | Medium (1.8) |

| Titanium Alloy Ti-6Al-4V | Fair (6/10) | 5-12 | 0.8-1.6 | High (3.2) |

| Engineering Ceramics | Poor (4/10) | 8-20 | 0.1-0.5 | Very High (4.5) |

| PEEK Polymer | Very Good (8/10) | 10-25 | 0.6-1.5 | Medium-High (2.5) |

Material-Specific Considerations

Metallic Materials

Metallic materials offer excellent mechanical properties but require specialized machining approaches:

- Aluminum Alloys: Best for high-volume production with excellent surface finish

- Stainless Steels: Ideal for medical applications requiring corrosion resistance

- Titanium Alloys: Preferred for aerospace and medical implants due to strength-to-weight ratio

Non-Metallic Materials

Non-metallic materials provide unique benefits for specific applications:

- Ceramics: Offer exceptional hardness and wear resistance for precision components

- Polymers: Provide electrical insulation and biocompatibility for medical devices

- Composites: Combine multiple material properties for specialized applications

Process Comparison & Advantages

Manufacturing Process Comparison

| Process Feature | Micro CNC Machining | Traditional Machining | 3D Printing | Micro Injection Molding |

|---|---|---|---|---|

| Minimum Feature Size | 10-50 μm | 100-500 μm | 20-100 μm | 50-200 μm |

| Material Range | Extensive | Limited | Very Limited | Moderate |

| Surface Finish | Excellent | Good | Poor | Very Good |

| Production Time (Prototype) | 1-3 days | 3-7 days | 0.5-2 days | 7-14 days |

| Cost (Low Volume) | Medium | High | Medium | Very High |

| Tolerance Control | ±1-5 μm | ±10-50 μm | ±20-100 μm | ±5-25 μm |

Key Advantages of Micro CNC Machining

Goldcattle Exclusive Data: Titanium alloy micro components produced using our advanced micro CNC processes demonstrated a 25% increase in fatigue life compared to conventionally machined parts (internal testing data, 2025).

Precision & Accuracy

Micro CNC machining achieves unparalleled precision with tolerances as tight as ±1μm, far exceeding the capabilities of traditional manufacturing methods. This level of accuracy is critical for applications in medical devices, aerospace guidance systems, and high-performance electronics.

Material Versatility

Unlike specialized processes that are limited to specific materials, micro CNC machining works with an extensive range of metals, ceramics, polymers, and composites. This versatility allows manufacturers to select the optimal material for each application without process constraints.

Cost-Effectiveness

For low to medium production volumes, micro CNC machining offers significant cost advantages over alternative processes. The elimination of expensive tooling and molds, combined with rapid setup times, makes it particularly economical for prototype development and small-batch production.

Design Freedom

Micro CNC machining supports complex geometries and intricate features that would be impossible or prohibitively expensive with other manufacturing methods. This design freedom enables innovation in product development and optimization of component performance.

Goldcattle Case Studies & Real-World Applications

Medical Sensor Component (2025)

Project: Custom titanium alloy micro components for medical pressure sensors

Challenges: 0.0005mm tolerance requirements, biocompatibility, high-volume production

Results: Successfully produced 50,000+ components with 99.8% yield, achieving precision measurements of ±0.0005mm

Impact: Enabled miniaturization of medical devices, reducing patient discomfort and improving diagnostic accuracy

Aerospace Guidance System (2025)

Project: Micro components for satellite attitude control systems

Challenges: Extreme temperature resistance, zero-defect requirements, ultra-precise tolerances

Results: Components passed vibration and thermal cycling tests with zero failures

Impact: Improved satellite reliability and extended operational lifespan

2026 Technology Trends & Innovations

Emerging Technologies

The micro CNC machining industry continues to evolve rapidly, with several key trends shaping the future of precision manufacturing:

AI-Enhanced Programming

Artificial intelligence is being integrated into CNC programming systems to optimize tool paths, predict tool wear, and reduce machining times. Goldcattle’s 2025 implementation of AI-based path optimization resulted in 15-20% faster production times while maintaining precision standards.

Sustainability Initiatives

Recycled materials and bio-compound integration are becoming increasingly important. Goldcattle has achieved 30-40% material reduction through optimized nesting and recycling programs, aligning with global sustainability goals.

Nanoscale Machining

Advancements in machine tool precision are pushing capabilities into the nanometer range. Current developments show promise for achieving tolerances as tight as 50nm for specialized applications.

Industry Growth Projections

| Application Sector | 2025 Market Size | 2030 Projected Size | CAGR | Driving Factors |

|---|---|---|---|---|

| Medical Devices | $1.2B | $2.1B | 12.1% | Aging population, minimally invasive procedures |

| Aerospace | $850M | $1.5B | 11.8% | Satellite constellations, UAV expansion |

| Electronics | $980M | $1.7B | 11.6% | 5G infrastructure, IoT devices |

| Automotive | $620M | $1.1B | 12.3% | Electric vehicles, autonomous systems |

Regulatory Landscape

European and American standards for precision manufacturing continue to evolve. Goldcattle maintains compliance with ISO 9001, AS9100, and RoHS certifications, ensuring products meet the highest quality and safety requirements across global markets.

Frequently Asked Questions

Micro CNC machining supports an extensive range of materials including:

- Metals: Aluminum alloys, stainless steels, titanium alloys, brass, copper

- Plastics: PEEK, ABS, nylon, PC, PTFE

- Ceramics: Alumina, zirconia, silicon carbide

- Composites: Carbon fiber, glass fiber, hybrid materials

Lead times vary based on complexity and quantity:

- Simple prototypes: 1-3 business days

- Complex prototypes: 3-7 business days

- Small production runs (10-100): 5-10 business days

- Medium production runs (100-1000): 10-15 business days

- Large production runs (1000+): 15-30 business days

Costs depend on multiple factors:

- Simple features: $50-200 per part (low volume)

- Complex features: $200-800 per part (low volume)

- Production runs: $10-50 per part (1000+ quantity)

- Materials: Titanium and ceramics command 2-4x premium over aluminum

Goldcattle maintains the following certifications:

- ISO 9001:2015 – Quality Management Systems

- AS9100D – Aerospace Quality Management

- ISO 13485 – Medical Devices Quality Management

- RoHS – Restriction of Hazardous Substances

- REACH – Registration, Evaluation, Authorization of Chemicals

Each technology has distinct advantages:

- Micro CNC: Better accuracy, wider material range, superior surface finish

- 3D Printing: Faster for complex geometries, no tooling required

- Cost Comparison: CNC more economical for metals, 3D printing better for low-volume plastic parts

Quality Assurance & Testing

Metrological Verification

Goldcattle employs a comprehensive quality assurance program utilizing state-of-the-art measurement equipment:

- Coordinate Measuring Machines (CMM) with 0.5μm accuracy

- Optical profilometers for surface finish analysis

- Laser micrometers for non-contact dimension verification

- X-ray inspection for internal feature validation

Testing Standards & Results

| Test Category | Standard | Goldcattle Performance | Industry Average |

|---|---|---|---|

| Dimensional Accuracy | ISO 10360-2 | ±1.2μm | ±3.5μm |

| Surface Roughness | ISO 4287 | Ra 0.12μm | Ra 0.35μm |

| Repeatability | ISO 10360-4 | 0.8μm | 2.1μm |

| Material Hardness | ASTM E18 | ±2 HRC | ±5 HRC |

Failure Analysis & Prevention

Goldcattle implements rigorous failure analysis protocols to continuously improve processes:

- Root cause analysis for all non-conforming parts

- Statistical process control (SPC) for real-time monitoring

- Preventive maintenance schedules for all equipment

- Operator training and certification programs

Goldcattle Capabilities & Certifications

Technical Specifications

- Machine Precision: Positioning accuracy ±1μm, repeatability ±0.5μm

- Spindle Speeds: Up to 80,000 RPM for micro machining

- Tool Capacity: 0.1mm to 20mm diameter tools

- Work Envelope: 400mm × 300mm × 200mm

- Inspection Equipment: CMM, optical comparators, laser micrometers

Quality Management System

Goldcattle maintains a comprehensive quality management system that encompasses every aspect of the manufacturing process:

- Documented procedures for all critical processes

- Traceability of all materials and components

- Continuous improvement programs

- Customer satisfaction monitoring and feedback systems

Goldcattle Advantage: With 15+ years of specialized experience in micro CNC machining, Goldcattle combines technical expertise with state-of-the-art equipment to deliver precision components that meet the most demanding requirements.