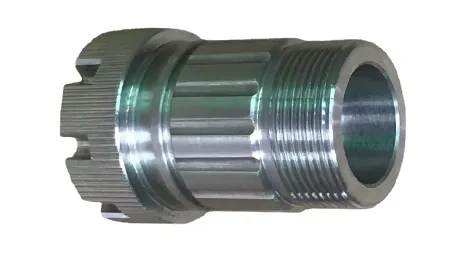

As a core component in the manufacture and assembly of machine tools, precision machine tool screws assume a variety of functions such as connection, fixation, transmission and positioning. Their precision, strength and durability are directly related to the overall performance and operational stability of machine tools. Therefore, customized precision machine screws are particularly important to meet the specific needs of different machine tools.

1. Precision machine screw production process

Material selection and pretreatment: According to the use of screws and performance requirements, selected high-strength, corrosion-resistant, wear-resistant alloy steel, stainless steel or titanium alloy and other materials. Materials need to undergo rigorous testing and pretreatment, such as pickling, phosphating, etc., in order to improve its surface quality and processing performance.

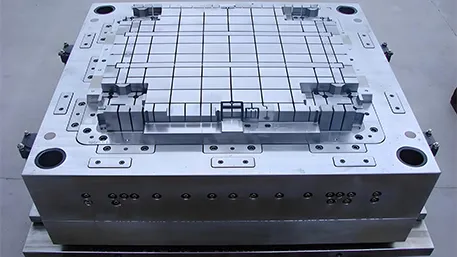

Precision design and manufacture of molds: According to the specifications, shape and accuracy requirements of the screw, precision design and manufacture of the corresponding injection or stamping molds. The precision and durability of the mold is directly related to the screw molding quality and production efficiency.

Molding and heat treatment: The material is processed into the initial shape of the screw by means of precision injection molding, stamping or machining. Subsequently, heat treatment, such as quenching, tempering, etc., to improve the hardness, strength and toughness of the screw.

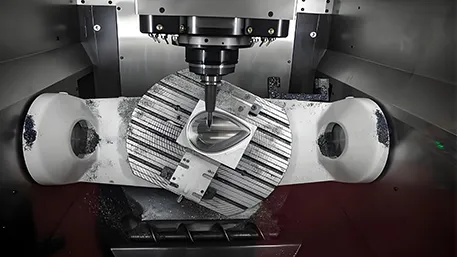

Precision machining and inspection: The preliminary shaped screws are subjected to precision machining, such as turning, milling, grinding, etc., in order to achieve the required accuracy and surface quality. At the same time, strict size measurement, performance test and appearance inspection are carried out to ensure that the quality of screws meets customer requirements and industry standards.

Surface treatment and packaging: The screws are subjected to surface treatment, such as zinc plating, blackening, plastic spraying, etc., in order to improve their corrosion resistance and aesthetics. Finally, packaging and labeling for storage, transportation and subsequent use.

2. Customization of precision machine screws

Specification customization: according to the specific needs of customers, provide a variety of specifications of screw customization services, including length, diameter, pitch, etc..

Shape customization: According to the special requirements of the machine tool, provide special shape screw customization services, such as hexagon head, hexagon head, flat head and so on.

Performance customization: According to the working environment of the machine tool, provide screws with different performance customization services, such as high-strength, corrosion resistance, wear resistance and so on.

Surface treatment customization: provide a variety of surface treatment customization services to meet the customer’s requirements on the appearance and corrosion resistance of screws.

Batch customization: according to the customer’s order quantity and delivery requirements, to provide efficient mass production services to ensure on-time delivery of high-quality screws.

3. Introduction of materials for precision machine screws

Material: alloy steel, stainless steel, titanium alloy, etc.

Characteristics:

High strength: alloy steel and titanium alloy screws have high tensile strength and yield strength, able to withstand large loads and torque.

Corrosion resistance: stainless steel screws have good corrosion resistance, can be in the wet, corrosive and other harsh environments such as long-term work.

Wear-resistant: after special treatment of the screw surface has a high hardness and wear resistance, can reduce wear and prolong the service life.

High precision: precision machine screws have high dimensional accuracy and surface quality, to meet the high precision requirements of machine tools for connectors.

Easy machinability: alloy steel and stainless steel and other materials have good machinability, easy to turn, milling, grinding and other precision machining.

4. Characteristics of precision machine tool screws of different materials

Alloy steel screws:

Tensile strength: ≥ 800MPa

Yield strength: ≥ 600MPa

Hardness: HRC30-50

Corrosion resistance: general (surface treatment required)

Use temperature range: -40℃ to +500℃

● Stainless steel screws:

Tensile strength: ≥500MPa

Yield strength: ≥200MPa

Hardness: HB≤220

Corrosion resistance: excellent (applicable to a variety of corrosive environments)

Operating temperature range: -196℃ to +800℃ (depending on the type of stainless steel)

●Titanium alloy screws:

Tensile strength: ≥400MPa

Yield strength: ≥300MPa

Hardness: HB≤130

Corrosion resistance: excellent (better than stainless steel)

Use temperature range: -253℃ to +600℃

Density: low (about 1/2 of steel)

Note: The above data is for reference only, the specific value may vary depending on the type of material, heat treatment process and manufacturer.

Customized Precision Machine Tool Screws Service FAQ

Q1: Can you provide customized service for precision machine screws?

A: Yes, we provide a full range of customized services for precision machine screws, including customization of specifications, shapes, properties, surface treatment and mass production.

Q2: What is the lead time for customized screws?

A: The lead time depends on the complexity and quantity of the screws and the customer’s lead time requirements. Generally speaking, we complete production and shipment within 7-15 working days after receiving the order.

Q3: What materials do you offer for screw customization?

A: We provide customized screws service in alloy steel, stainless steel, titanium alloy and other materials to meet customers’ different performance requirements.

Q4: How to ensure the quality of customized screws?

A: We have a perfect quality management system and advanced production equipment, each batch of screws are subjected to strict quality inspection and performance testing to ensure that the quality of screws meets customer requirements and industry standards.

Q5: What if I am not satisfied with the customized screws?

A: If customers are not satisfied with the customized screws, we will return or re-customize the screws according to the specific situation in order to meet the customer’s expectations and needs. At the same time, we provide technical support and after-sales service to help customers solve problems encountered during use.