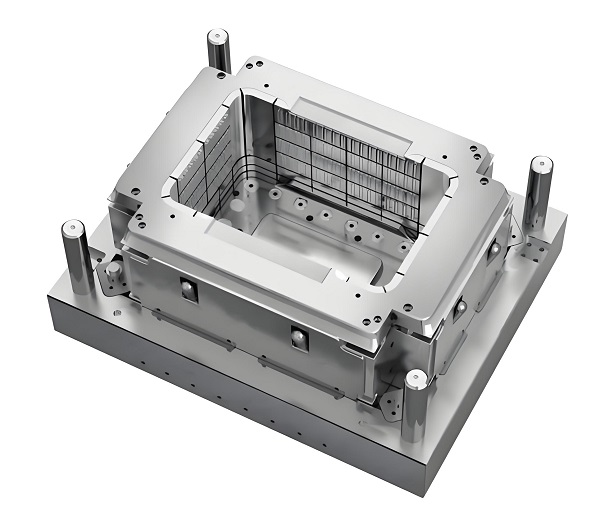

Storage box mold is a key tool for manufacturing storage boxes, its design accuracy and manufacturing quality directly affect the appearance, dimensional accuracy and production efficiency of storage boxes. There are many kinds of storage box molds, according to the different shapes, sizes and uses of storage boxes, the structure of the mold and the manufacturing process are also different.

1.Storage box mold production process

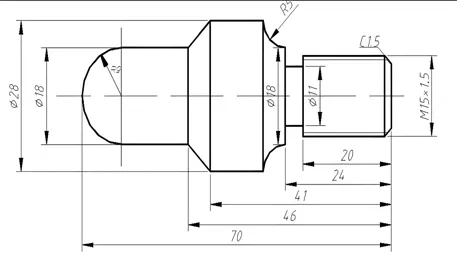

Design stage: according to the customer’s demand and the design drawings of the storage box, the three-dimensional modeling and detailed design of the mold. The design process needs to consider the structural strength of the mold, the choice of parting surface, cooling system arrangement and other factors.

Material selection and procurement: According to the design requirements of the mold and the use of the environment, select the appropriate mold materials, such as high-quality alloy steel, stainless steel, aluminum alloy and so on. At the same time, purchase the corresponding standard parts and accessories.

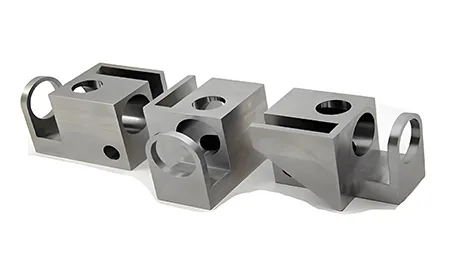

Mould processing: Adopt advanced CNC machining equipment and technology to carry out precision machining of the mold, including roughing, semi-finishing and finishing three stages. Processing process needs to strictly control the processing accuracy and surface quality.

Assembly and debugging: the processed mold parts are assembled and debugged to ensure smooth opening and closing of the mold, accurate positioning and good cooling effect.

Mold trial and acceptance: Use the mold for mold trial to check the molding quality and dimensional accuracy of the storage box. According to the results of the trial mold, make necessary adjustments and optimization to the mold until it meets the customer’s requirements.

2.Customized storage box mold

Communicate with customers: Communicate fully with customers to understand the shape, size, material, quantity and delivery time of the storage box and other specific requirements.

Program design and quotation: according to the customer’s needs, develop the design of the mold, including mold structure, material selection, manufacturing cycle. At the same time, calculate the cost of the mold according to the design scheme, and provide customers with a detailed quotation.

Contract signing and prepayment: After both parties confirm the quotation and design scheme, sign the customized contract and collect a certain percentage of prepayment.

Mould manufacturing and follow up: according to the time point agreed in the contract, manufacture and process the mold. During the manufacturing process, we will keep communicating with customers and report the manufacturing progress and problems encountered in time.

Acceptance and delivery of the mold: After the mold manufacturing is completed, acceptance and testing will be carried out. After acceptance, deliver the mold to the customer and collect the remaining payment.

3.Storage box mold material introduction

Material: high quality alloy steel, stainless steel, aluminum alloy and so on.

Characteristics:

High strength: these materials have high strength and hardness, and can withstand all kinds of stresses and impacts during the manufacturing and use of the mold.

Abrasion resistance: they have good abrasion resistance and can resist the wear and damage caused by friction during the use of the molds.

Corrosion resistance: strong resistance to acid, alkali and other chemical substances, to prevent the mold in the process of use due to corrosion and failure.

Easy processing: good processing performance, easy to cut, weld, polish and other processing operations.

4. Different materials storage box mold characteristics

Product:

High quality alloy steel storage box mold

Data: high strength and hardness, good wear resistance, long service life. Suitable for manufacturing large and heavy storage box mold.

Stainless steel storage box mold

Data: High corrosion resistance, high surface finish, easy to clean and maintain. Suitable for manufacturing storage box molds that need to be exposed to humid or corrosive environment for a long time.

Aluminum Storage Box Mould

Data: Low density, light weight, easy to process and mold. Good thermal conductivity and corrosion resistance. Suitable for manufacturing small, lightweight storage box molds, as well as molds that require rapid heat dissipation.

Other materials (e.g. titanium alloys, ceramics, etc.)

Data (example): titanium alloy molds have the characteristics of high strength, low density, corrosion resistance and high temperature resistance, but the cost is higher; ceramic molds have the characteristics of high hardness, high abrasion resistance and high corrosion resistance, but fragile and difficult to process.

Customized Storage Box Mould FAQ

Q1:How long is the customized cycle time for storage box mould?

A1:The customization cycle depends on the complexity of the mold, material selection and production arrangement and other factors. Generally speaking, the customization cycle for simple molds is between a few weeks to a few months, and complex molds may take longer.

Q2: How to ensure the precision of the storage box mold?

A2: We ensure the precision and dimensional stability of the molds through advanced CNC machining equipment and processes, as well as strict quality control processes. Meanwhile, we adopt high-precision measuring instruments for inspection and testing to ensure that the mold meets the design requirements.

Q3:How long is the life of the storage box mold?

A3:The life span of the mold depends on many factors, such as material selection, manufacturing process, usage environment and maintenance. High-quality alloy steel and stainless steel molds have a high service life, after reasonable use and maintenance, can maintain a good working condition for a long time.

Q4:How to calculate the price of storage box mold?

A4:The price of the mold is calculated according to the material, design complexity, manufacturing difficulty and quantity. We will provide a detailed quotation according to customers’ requirements and sign a customized contract after both parties confirm.

Q5:How to maintain the storage box mold to extend its service life?

A5:Regularly clean the dust and dirt on the surface of the mold to keep the mold clean and dry; avoid excessive impact and collision on the mold; regularly inspect and maintain the mold, such as replacing worn parts, adjusting the mold gap, etc.; reasonably control the use of the mold temperature and pressure and other parameters.