Small injection molded parts are a vital component in the realm of plastic products, distinguished by their small size, high precision, and complex structures. They are widely utilized across various industries such as electronics, automobiles, medical devices, and home appliances. This manual aims to provide a comprehensive introduction to our custom small injection molded parts service, including production processes, production workflows, material selection, applications, customization services, and a comparison of characteristics among different materials.

1. Production Processes for Small Injection Molded Parts

The production processes for small injection molded parts primarily encompass mold design, mold manufacturing, injection molding, finishing treatments, and quality inspection.

Mold Design: Based on customer needs and product characteristics, conduct three-dimensional design and simulation analysis of the mold to ensure a reasonable mold structure and smooth injection molding process.

Mold Manufacturing: Utilize advanced CNC machining technology and precision measurement equipment to manufacture high-quality injection molds.

Injection Molding: Heat the plastic raw material to a molten state, inject it into the mold under high pressure through an injection molding machine, and allow it to cool to form the desired shape of the small injection molded part.

Finishing Treatments: Perform deburring, grinding, polishing, and other treatments on the injection molded parts to enhance their surface quality and aesthetic appeal.

Quality Inspection: Conduct quality inspections on the injection molded parts in terms of dimensions, appearance, and performance to ensure they meet customer requirements.

2. Production Workflow for Small Injection Molded Parts

The production workflow for small injection molded parts includes the following steps:

Needs Analysis: Communicate with customers to understand product requirements, quantities, delivery schedules, and other information.

Mold Design: Based on product drawings or samples, conduct mold design and produce mold drawings.

Mold Manufacturing: Manufacture the injection mold according to the mold drawings.

Injection Molding: Adjust the injection molding machine, conduct injection molding trials, and tweak process parameters to ensure product quality.

Finishing Treatments: Perform finishing treatments on the injection molded parts to improve their appearance quality.

Quality Inspection: Conduct rigorous quality inspections on the injection molded parts to ensure they meet customer requirements.

Packaging and Shipment: Package the products and ship them according to customer specifications.

3. Materials for Small Injection Molded Parts

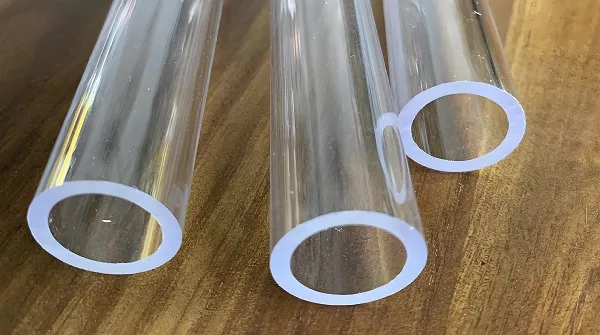

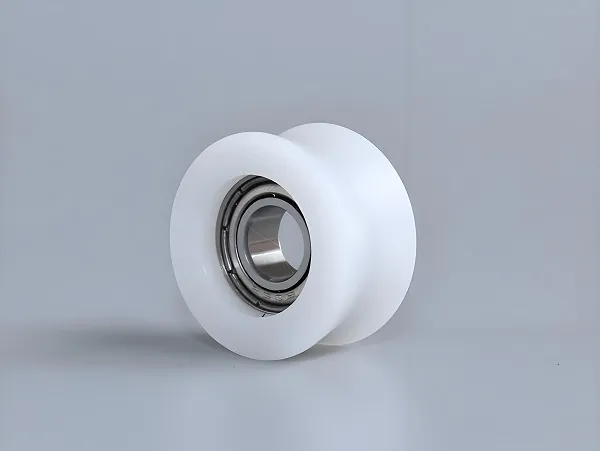

Commonly used materials for small injection molded parts include polypropylene (PP), polyethylene (PE), polystyrene (PS), polycarbonate (PC), and nylon (PA). These materials possess different physical and chemical properties, suitable for different applications.

4. Applications of Small Injection Molded Parts

Due to their high precision, low cost, and ease of processing, small injection molded parts are widely used in the following fields:

Electronics: Mobile phone cases, keyboard keys, electronic connectors, etc.

Automobiles: Dashboard components, interior trim, sensor housings, etc.

Medical Devices: Syringes, infusion sets, surgical instruments, etc.

Home Appliances: Remote control cases, washing machine control panels, refrigerator door handles, etc.

5. Customization of Small Injection Molded Parts

We offer comprehensive customization services for small injection molded parts, including:

Product Design: Based on customer needs, conduct product design and provide 3D models.

Mold Design and Manufacturing: Conduct mold design based on product design and manufacture high-quality molds.

Material Selection: Select appropriate plastic materials based on customer requirements and product characteristics.

Injection Molding: Utilize advanced injection molding technology and equipment to produce high-quality small injection molded parts.

Finishing Treatments: Perform finishing treatments on the injection molded parts to improve their appearance quality.

Quality Inspection: Conduct strict quality inspections on the injection molded parts to ensure they meet customer requirements.

6. Characteristics Comparison of Small Injection Molded Parts Made from Different Materials

| Material Type | Density (g/cm³) | Tensile Strength (MPa) | Flexural Strength (MPa) | Impact Strength (kJ/m²) | Heat Resistance (℃) |

|---|---|---|---|---|---|

| Polypropylene (PP) | 0.90-0.91 | 20-30 | 25-35 | 2-10 | 100-120 |

| Polyethylene (PE) | 0.92-0.96 | 10-25 | 15-30 | 1-5 | 80-100 |

| Polystyrene (PS) | 1.04-1.06 | 30-50 | 40-70 | 2-10 | 70-90 |

| Polycarbonate (PC) | 1.20-1.22 | 60-100 | 70-120 | 20-60 | 120-150 |

| Nylon (PA) | 1.10-1.15 | 50-100 | 80-150 | 5-20 | 150-200 |

Custom Small Injection Molded Parts FAQ

Q1: What is the customization cycle for small injection molded parts?

A: The customization cycle depends on various factors such as product design, mold manufacturing, and injection molding. It typically ranges from a few weeks to several months. Please communicate with our customer service personnel for a specific timeline.

Q2: How is the price of small injection molded parts calculated?

A: The price is determined based on multiple factors, including product design, mold manufacturing, material selection, and injection molding. Please provide detailed product requirements and quantities, and we will provide you with an accurate quotation.

Q3: How is the quality of small injection molded parts guaranteed?

A: We utilize advanced production equipment and technology, strictly adhering to the ISO quality management system for production and management. Additionally, we conduct rigorous quality inspections on the injection molded parts to ensure they meet customer requirements.

Q4: Can small injection molded parts undergo surface treatment?

A: Yes, we offer various surface treatment services, such as painting, plating, and printing. Please select the appropriate surface treatment method based on your needs.

Through the introduction in this manual, we hope you have a deeper understanding of our custom small injection molded parts service. If you have any questions or needs, please feel free to contact us, and we will be happy to assist you.