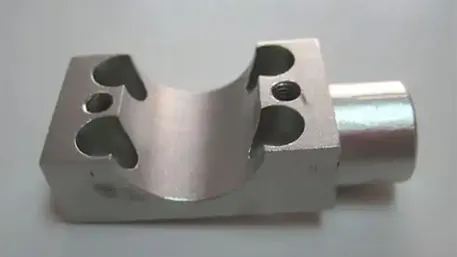

Small turning parts are one of the indispensable precision parts in the machinery manufacturing industry, which are processed through turning and have high precision, high surface quality and good mechanical properties. They are widely used in various equipments and systems, playing a key role in connection, transmission, support and so on.

1. Small turning parts process introduction

The machining process of small turning parts mainly includes the following steps:

Drawing design: according to the product requirements, draw detailed drawings of the parts, clear size, tolerance, material and other parameters.

Material preparation: according to the requirements of the drawings, select the appropriate raw materials, such as steel, aluminum, copper, plastic and so on.

Turning Processing: Utilize the lathe for cutting processing, through the relative motion of the tool and the workpiece, remove the excess material and form the required shape and size.

Quality Inspection: Quality inspection of the finished small turning parts, including dimensional accuracy, surface roughness, shape and positional tolerances.

Surface treatment: surface treatment, such as galvanizing, painting, polishing, etc., is carried out according to the need to improve the corrosion resistance and aesthetics of the parts.

2. Small turning parts production process

The production process of small turning parts usually includes the following links:

Raw material procurement: choose the raw material supplier that meets the requirements and purchase the required materials.

Process development: according to the parts drawings and process requirements, the development of detailed machining process.

Processing production: according to the process flow, using lathes for turning processing, forming the required shape and size.

Quality control: During the production process, quality control is carried out for each process to ensure product quality.

Finished Product Inspection: Finished product inspection is carried out on the processed small turned parts to ensure compliance with the design requirements and quality standards.

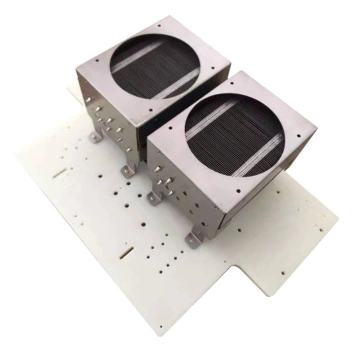

3. Application areas of small turned parts

Small turning parts are widely used in the following fields:

Automobile manufacturing: used in engine, transmission system, suspension system and other key components.

Electronic and electrical appliances: for connectors, switches, sensors and other precision parts.

Medical equipment: used for surgical instruments, testing equipment and other precision parts.

Aerospace: for precision parts of aerospace equipment such as airplanes and rockets.

Other fields: such as toys, stationery, clocks and watches and other precision parts of the industry.

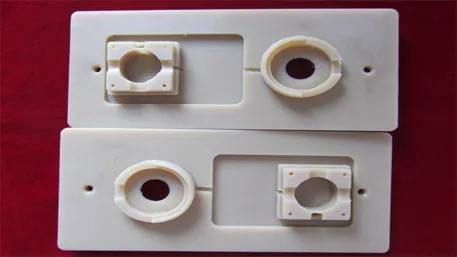

4. Small turning parts processing materials

Small turning parts processing materials are varied, common including:

Metal materials: such as steel, aluminum, copper, stainless steel and so on.

Non-metallic materials: such as plastic, rubber, ceramics, etc..

Composite materials: such as carbon fiber, glass fiber and so on.

When choosing the material, you need to consider the environment in which the part is used, the force situation, corrosion resistance and other factors.

5. Customization of small turning parts

Customization of small turning parts needs to follow the following steps:

Define the requirements: According to the product requirements, define the dimensions, tolerances, materials and other parameters of the parts.

Drawing design: according to the requirements, draw detailed drawings of the parts.

Selection of suppliers: choose the turning parts suppliers with rich experience and good reputation.

Communicate and confirm: Communicate with the supplier about the drawing requirements, confirm the machining program, delivery time and so on.

Production acceptance: Acceptance of the customized small turned parts to ensure compliance with the design requirements and quality standards.

Small Turned Parts FAQ

Q1: What is the precision of small turning parts?

A: The precision of small turning parts depends on the precision of lathe and processing technology. Generally speaking, the precision can reach micron level.

Q2:What are the considerations for material selection for small turning parts?

A: When choosing materials, you need to consider the environment in which the parts are used, the force situation, corrosion resistance and other factors. The machining performance and cost of the material also need to be considered.

Q3: How long does it take to customize small turning parts?

A: The time for customized small turned parts depends on factors such as the complexity of the drawings, the procurement cycle of the material, and the machining capability. Generally speaking, it takes several days to several weeks from drawing confirmation to delivery.

Q4: How to guarantee the quality of small turned parts?

A: To ensure the quality of small turned parts, we need to start from raw material procurement, machining process development, production monitoring, finished product inspection and so on. At the same time, it is also necessary to conduct strict screening and evaluation of suppliers.

Q5:How to calculate the price of small turning parts?

A: The price of small turning parts is usually calculated according to the complexity of drawings, the cost of materials, machining hours and other factors. The specific price needs to be determined after communicating with the supplier.

Through the above introduction, I believe you have a better understanding of customized small turning parts. If you have any questions or needs, please feel free to contact us.